Silicon carbide (SiC) exhibits outstanding wear and corrosion resistance due to its unique physical and chemical properties.

In terms of wear resistance, the Mohs hardness of silicon carbide can reach 9.5, second only to diamond and boron nitride. Its wear resistance is equivalent to 266 times that of manganese steel and 1741 times that of high chromium cast iron.

In terms of corrosion resistance, silicon carbide has extremely high chemical stability and exhibits excellent resistance to strong acids, alkalis, and salt solutions. Meanwhile, silicon carbide also has high corrosion resistance to molten metals such as aluminum and zinc, and is commonly used in crucibles and molds in the metallurgical industry.

At present, silicon carbide combined with superhard structure and its chemical inertness has been widely used in industries such as mining, steel, and chemical, becoming an ideal material choice under extreme working conditions.

|

material |

wear resistance |

corrosion resistance |

high temperature performance |

Economic(long-term) |

|

Silicon carbide |

Extremely high |

Extremely strong |

Excellent(<1600℃) |

High |

|

Alumina ceramics |

High |

Strong |

Average(<1200℃) |

Medium |

|

Metal alloy |

Medium |

Weak (requiring coating) |

Weak(prone to oxidation) |

Weak |

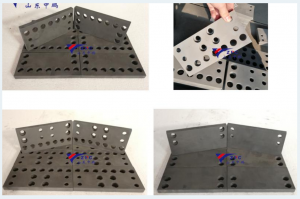

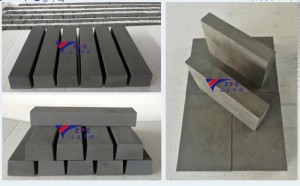

Silicon carbide wear-resistant block is an important classification in silicon carbide products.The wear-resistant and corrosion-resistant properties of silicon carbide make it widely used in grinding equipment such as mine crushers and ball mills, reducing frequent equipment replacement caused by wear and thus lowering machine maintenance costs.

The following is a comparison between silicon carbide wear-resistant blocks and other traditional material wear-resistant blocks:

|

Hardness and Wear Resistance |

Silicon carbide wear-resistant block |

Traditional materials |

|

Hardness and Wear Resistance |

Mohs hardness 9.5, extremely strong wear resistance (life increased by 5-10 times) |

High chromium cast iron has low hardness (HRC 60~65), and alumina ceramics are prone to brittle cracking |

|

Corrosion resistance |

Resistant to strong acids and alkalis |

Metals are prone to corrosion, while alumina has average acid resistance |

|

High temperature stability |

Temperature resistance of 1600 ℃, non oxidizing at high temperatures |

Metal is prone to deformation at high temperatures, while alumina has a temperature resistance of only 1200 ℃ |

|

Thermal conductivity |

120 W/m · K, fast heat dissipation, thermal shock resistance |

Metal has good thermal conductivity but is prone to oxidation, while ordinary ceramics have poor thermal conductivity |

|

Economic |

Long lifespan and low overall cost |

Metals require frequent replacement, ceramics are fragile, and long-term costs are high |

Post time: Mar-18-2025