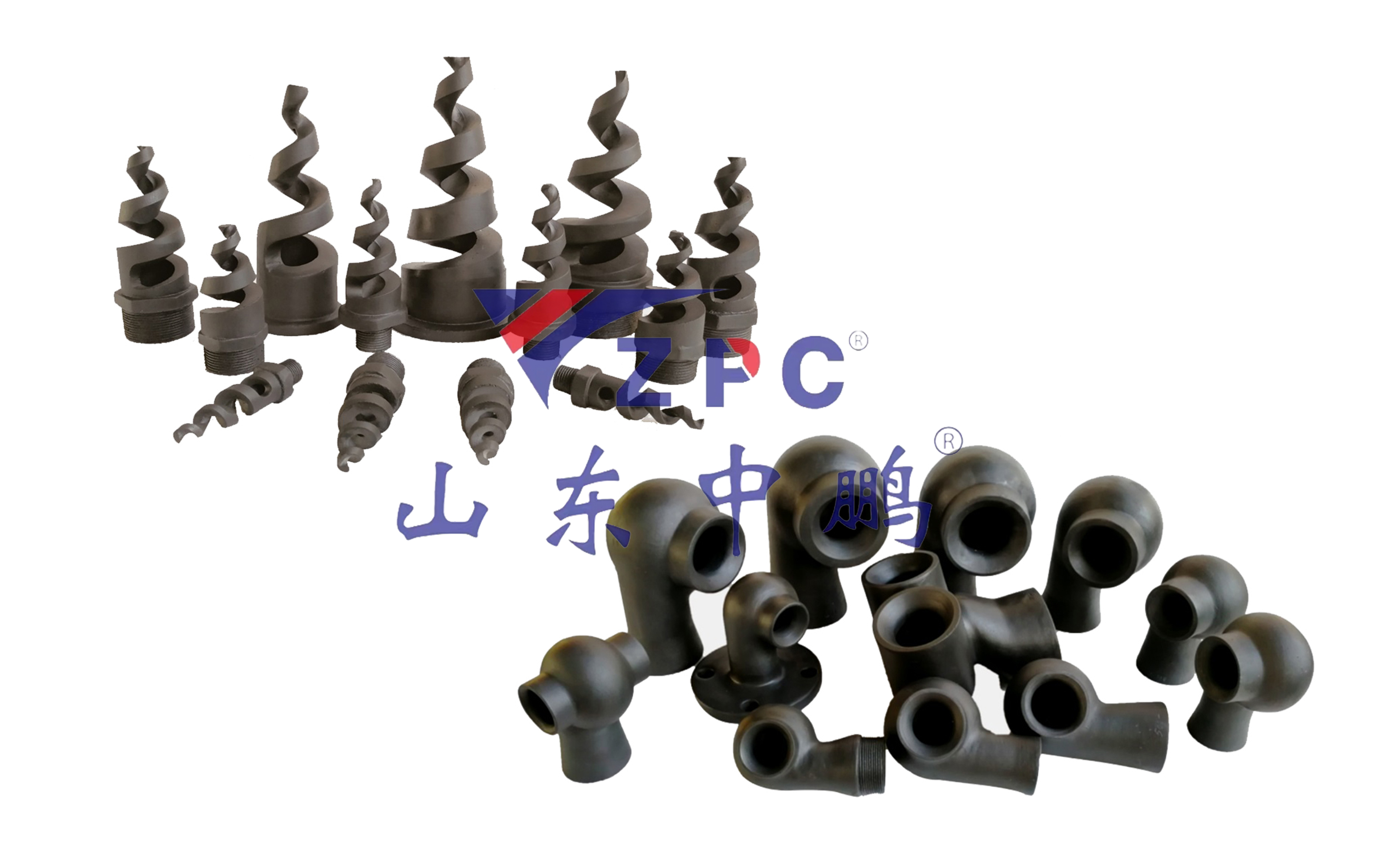

As the core component of modern flue gas purification systems, silicon carbide FGD Nozzles play a crucial role in industrial fields such as thermal power and metallurgy. This silicon carbide ceramic nozzle has successfully solved the technical bottleneck of traditional metal nozzles under strong corrosion and high wear conditions through innovative structural design and material breakthroughs, greatly improving desulfurization efficiency.

1、 Material properties lay the foundation for performance

The Mohs hardness of silicon carbide ceramics reaches 9.2, second only to diamond, and its fracture toughness is three times that of alumina ceramics. This covalent crystal structure endows the material with excellent abrasion resistance, and under the impact of high-speed slurry containing gypsum crystals (flow rate up to 12m/s), the surface wear rate is only 1/20 of that of metal nozzles. In an acid-base alternating environment with a pH value of 4-10, the corrosion resistance rate of silicon carbide is less than 0.01mm/year, which is much better than the 0.5mm/year of 316L stainless steel.

The thermal expansion coefficient of the material (4.0 × 10 ⁻⁶/℃) is close to that of steel, and it can still maintain structural stability under a temperature difference of 150 ℃. Silicon carbide ceramics prepared by reaction sintering process have a density of over 98% and a porosity of less than 0.5%, effectively preventing structural damage caused by medium infiltration.

2、 Precision atomization mechanism and flow field control

The silicon carbide spiral nozzle significantly increases the swirling speed of the slurry, and with precise outlet aperture, it breaks down the limestone slurry into small and uniform droplets. The hollow conical spray field coverage rate formed by this structure is very large, and the residence time of droplets in the tower is extended to 2-3 seconds, 40% higher than that of traditional nozzles.

3、 System matching and engineering optimization

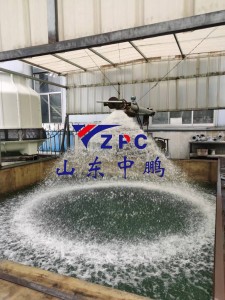

In a typical spray tower, silicon carbide FGD nozzles arranged in a chessboard manner are used, with spacing of 1.2-1.5 times the spray cone diameter, forming 3-5 layers of overlay. This arrangement ensures that the cross-sectional coverage of the desulfurization tower exceeds 200%, ensuring sufficient contact between the flue gas and the slurry. With an empty tower flow rate of 3-5 m/s, the system pressure loss is controlled within the range of 800-1200 Pa.

Operational data shows that the desulfurization efficiency of the FGD system using silicon carbide nozzles remains stable at over 97.5%, and the moisture content of gypsum by-products is reduced to below 10%. The equipment maintenance cycle has been extended from 3 months for metal nozzles to 3 years, and the cost of spare parts replacement has decreased by 70%.

The application of this FGD nozzle marks a leap from extensive to precise environmental protection equipment. With the maturity of 3D printing ceramic technology, topology optimization design of flow channel structure may be realized in the future, which can further improve atomization efficiency by 15-20% and promote ultra-low emission technology to enter a new stage of development.

Post time: Mar-24-2025