Beside the scorching furnace in the steel plant, by the churning acid pool in the chemical plant, and in the core components of high-speed precision machinery, a seemingly ordinary gray black ceramic is quietly refreshing human understanding of material properties. Silicon carbide ceramics – this artificially synthesized material born in the late 19th century, after a century of technological refinement, is reshaping the material selection rules of modern industry with three disruptive advantages.

Superpower One: “Philosophy of Hardness”

If traditional ceramics are fragile glass beauties, silicon carbide can be called the kung fu master of the ceramic industry. It has a hardness comparable to diamonds, but is well versed in the wisdom of “overcoming hardness with softness” – on high wear battlefields, when metal materials are defeated by repeated friction, silicon carbide ceramics can always handle it calmly – its wear resistance is more than 8 times that of traditional hard alloys. This characteristic enables pipelines, equipment, etc. lined with silicon carbide ceramics to have a longer service life, greatly reducing the cost of frequent replacement and the losses caused by downtime.

Superpower 2: High Temperature ‘Calm Faction’

When ordinary metals soften and deform in flames, when conventional ceramics crack and disintegrate at high temperatures, silicon carbide remains steadfast like an iceberg, able to maintain its original color even when baked at 1200 ℃. This “high-temperature cooling” characteristic makes it an irreplaceable heat-resistant lining in glass furnaces and metal heat treatment equipment. Even better, its thermal expansion and contraction are almost synchronized with silicon materials, making it a golden partner for semiconductor manufacturing equipment.

Superpower Three: The Unbreakable Shield Corrupts the Battlefield

Faced with the “death corrosion” of concentrated sulfuric acid and the “flame baptism” of molten aluminum, silicon carbide exhibits extraordinary calmness. In the chemical workshop, the service life of desulfurization nozzles made of this ceramic can be several times that of other industrial materials; In the electrolysis workshop, its corrosion-resistant lining has bid farewell to the nightmare of frequent replacement of equipment.

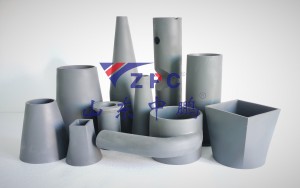

From desulfurization nozzles in the chemical industry to high-temperature resistant components baked at high temperatures, from wear-resistant liners in high wear environments to key modules in precision instruments, silicon carbide ceramics are writing a new chapter in the evolution of industrial materials – silicon carbide ceramic materials are no longer simply metal substitutes, but the master key for engineers to unlock technological bottlenecks. Shandong Zhongpeng has always been committed to researching and producing high-quality silicon carbide ceramic industrial products, striving to perfectly embody the performance advantages of silicon carbide materials in finished products, ensuring the best product and service experience for customers while meeting their requirements.

If you are also interested in our products, please visit Shandong Zhongpeng for more product details, or call (+86) 15254687377 to learn more about customized silicon carbide ceramics.

Post time: Apr-08-2025