Silicon carbide is a synthetic ceramic composed of silicon and carbon atoms arranged in a tightly bonded crystal structure. This unique atomic arrangement gives it remarkable properties: it is nearly as hard as diamond (9.5 on the Mohs scale), three times lighter than steel, and capable of withstanding temperatures over 1,600°C. Additionally, its high thermal conductivity and chemical stability make it ideal for high-stress environments.

Military Applications: Shielding Lives in Combat

For decades, military forces have sought materials that balance protection and mobility. Traditional steel armor, while effective, adds significant weight to vehicles and personnel. Silicon carbide ceramics solved this dilemma. When used in composite armor systems—often layered with materials like polyethylene or aluminum—SiC ceramics excel at disrupting and dispersing the energy of bullets, shrapnel, and explosive fragments.

Modern military vehicles, body armor plates, and helicopter seats increasingly incorporate SiC ceramic panels. For instance, the U.S. Army’s next-generation combat helmets utilize SiC-based composites to reduce weight while maintaining protection against rifle rounds. Similarly, lightweight ceramic armor kits for armored vehicles improve mobility without compromising safety.

Civilian Adaptations: Safety Beyond the Battlefield

The same properties that make SiC ceramics invaluable in warfare are now being harnessed for civilian protection. As manufacturing costs decline, industries are adopting this “super ceramic” in creative ways:

1. Automotive Armor: High-profile executives, diplomats, and VIP vehicles now use discreet SiC ceramic-reinforced panels for bullet resistance, combining luxury with security.

2. Aerospace & Racing: Formula 1 teams and aircraft manufacturers embed thin SiC ceramic plates in critical components to guard against debris impacts at extreme speeds.

3. Industrial Safety: Workers in hazardous environments (e.g., mining, metalworking) wear cutting-resistant gear reinforced with SiC ceramic particles.

4. Consumer Electronics: Experimental uses include ultra-durable smartphone cases and heat-resistant casings for electric vehicle batteries.

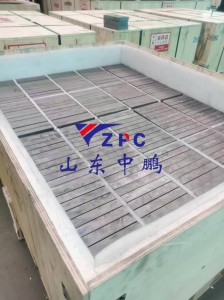

The most widespread civilian application, however, lies in ceramic protective plates. These lightweight panels are now found in:

- Firefighter gear to deflect falling debris

- Drone housings for collision protection

- Motorcycle riding suits with abrasion-resistant armor

- Security screens for banks and high-risk facilities

Challenges and Future Prospects

While silicon carbide ceramics offer unparalleled advantages, their brittleness remains a limitation. Engineers are addressing this by developing hybrid materials—for example, embedding SiC fibers in polymer matrices—to enhance flexibility. Additive manufacturing (3D printing) of SiC components is also gaining traction, enabling complex shapes for custom protection solutions.

From stopping bullets to safeguarding everyday lives, silicon carbide ceramics epitomize how military innovation can evolve into civilian lifesaving tools. As research continues, we may soon see SiC-based armor in earthquake-resistant building materials, wildfire-resistant infrastructure, or even wearable tech for extreme sports. In a world where safety demands grow ever more complex, this extraordinary ceramic stands ready to meet the challenge—one lightweight, ultra-tough layer at a time.

Post time: Mar-20-2025