Reaction-sintered silicon carbide ceramic, also known as RS-SiC, is an advanced ceramic material that has attracted widespread attention due to its excellent performance and wide range of applications. These ceramics are produced through a process called reactive sintering, which involves carbon and silicon reacting at high temperatures to form silicon carbide. The resulting material has excellent mechanical, thermal and chemical properties, making it suitable for a variety of industrial applications.

One of the main advantages of reaction-sintered silicon carbide ceramics is its exceptional hardness and wear resistance. These properties make them ideal for use in demanding environments such as mining, where equipment is subject to wear and erosion. RS-SiC components such as wear-resistant liners, nozzles and impellers are widely used in mining operations to improve the durability and performance of equipment exposed to harsh materials and conditions. The superior wear resistance of RS-SiC ceramics helps minimize downtime and maintenance costs, making it the first choice for mining applications.

In addition to mining, reaction-sintered silicon carbide ceramics are widely used in the power industry. RS-SiC’s excellent thermal conductivity and high temperature stability make it an ideal material for components in power generation and distribution systems. These ceramics are used in applications such as high-temperature heating elements, thermocouple protection tubes, and insulating components for electrical insulation. RS-SiC is able to withstand extreme temperatures and thermal shock, making it a reliable choice for critical components in power plants and electrical systems.

Furthermore, the chemical inertness of reaction-sintered silicon carbide ceramics makes it suitable for use in corrosive environments. They are resistant to chemical attack and oxidation and are used in the chemical processing, metallurgical and semiconductor manufacturing industries. RS-SiC components are used in processes involving corrosive chemicals, molten metals and high-temperature gases where conventional materials can degrade or fail. The corrosion resistance and stability of RS-SiC ceramics help increase equipment longevity and reliability in these challenging environments.

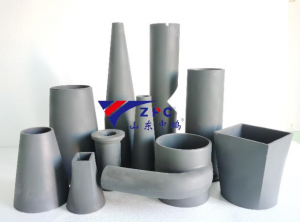

As the largest manufacturer of customized silicon carbide ceramic special-shaped parts in China, our company is committed to providing tailor-made high-quality RS-SiC parts to meet the specific requirements of different industries. We offer a variety of precision-engineered ceramic parts, including complex geometries and intricate designs, to meet our customers’ unique needs. Our expertise in reactive sintering technology allows us to produce complex shapes with tight tolerances, ensuring optimal performance and service life of ceramic components in a variety of applications.

The versatility of reaction-sintered silicon carbide ceramics extends beyond its mechanical and chemical properties. These ceramics also exhibit excellent electrical insulation, low thermal expansion and high stiffness, making them suitable for use in advanced engineering applications. Their ability to maintain dimensional stability at high temperatures and harsh environments further enhances their appeal in the aerospace, automotive and defense industries. RS-SiC components are used in aerospace propulsion systems, automotive braking systems and armor applications, where their superior properties help improve performance and reliability.

In summary, reaction-sintered silicon carbide ceramics offer a compelling combination of properties that make them indispensable in a wide range of industrial applications. Its exceptional hardness, wear resistance, thermal conductivity and chemical inertness make it the first choice for demanding environments in mining, power generation, chemical processing and other industries. As a leading manufacturer of customized silicon carbide ceramic special-shaped parts, our company is committed to providing innovative solutions that leverage the unique advantages of RS-SiC to meet the ever-changing needs of our customers. We focus on quality, precision and customization, and are committed to advancing the application of reaction-sintered silicon carbide ceramics in various fields, contributing to improving the performance, efficiency and reliability of key industrial processes.

Post time: Jul-30-2024