-

In industrial scenarios such as mining beneficiation, chemical separation, and power desulfurization, there are always some inconspicuous but crucial components, and the industrial silicon carbide sand settling nozzle is one of them. Many people may feel unfamiliar with this name for the first ti...Read more »

-

Continuous production is the key to improving efficiency in high-temperature kilns in industries such as ceramics and glass. The workpiece needs to move smoothly and be uniformly heated at high temperatures, and the core component that achieves all of this is the seemingly ordinary but significan...Read more »

-

You may not have noticed that in the high-temperature furnaces of factories such as steel and ceramics, there is an inconspicuous but crucial component – the burner sleeve. It is like the “throat” of a furnace, responsible for stabilizing flames and protecting equipment. Among m...Read more »

-

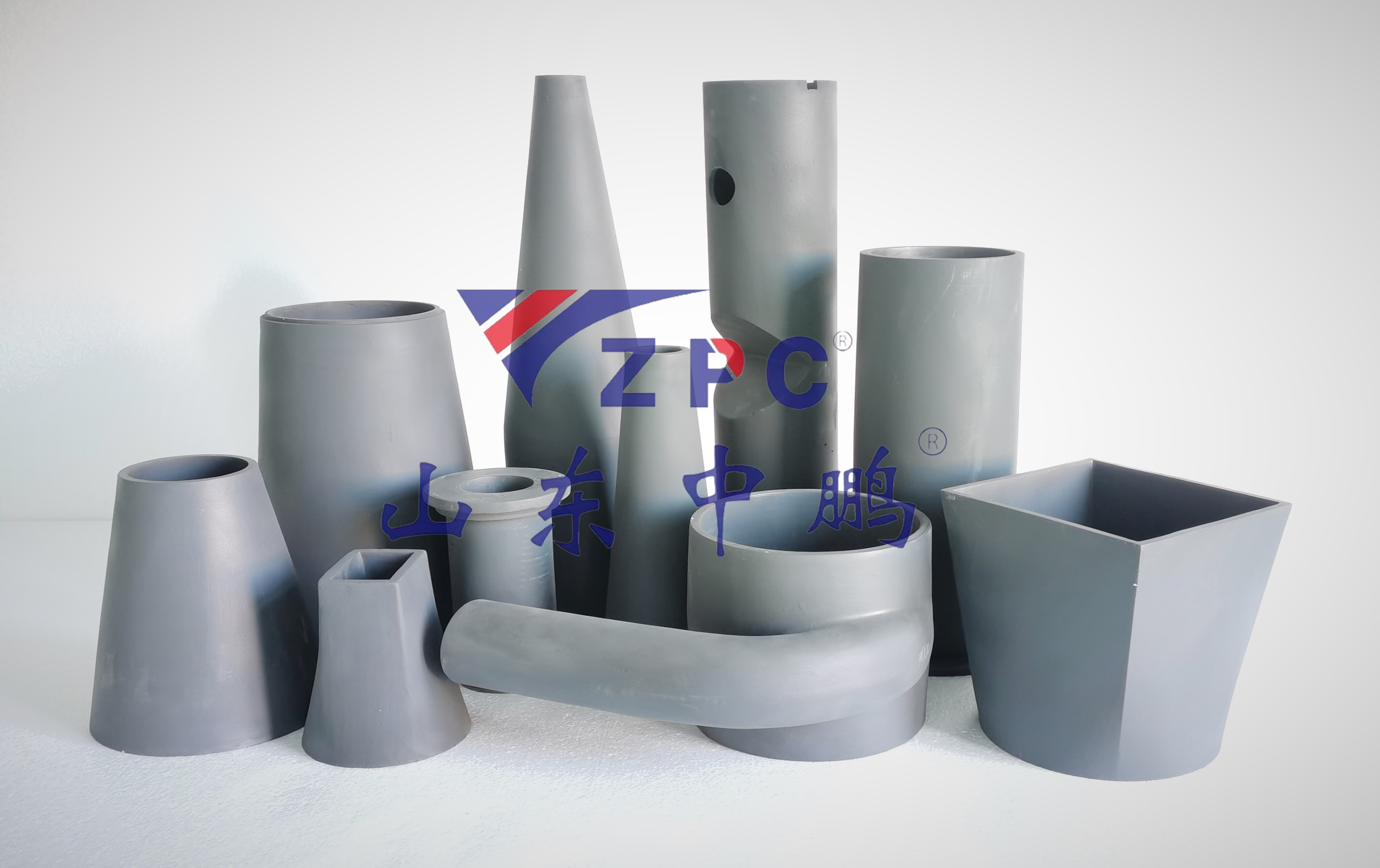

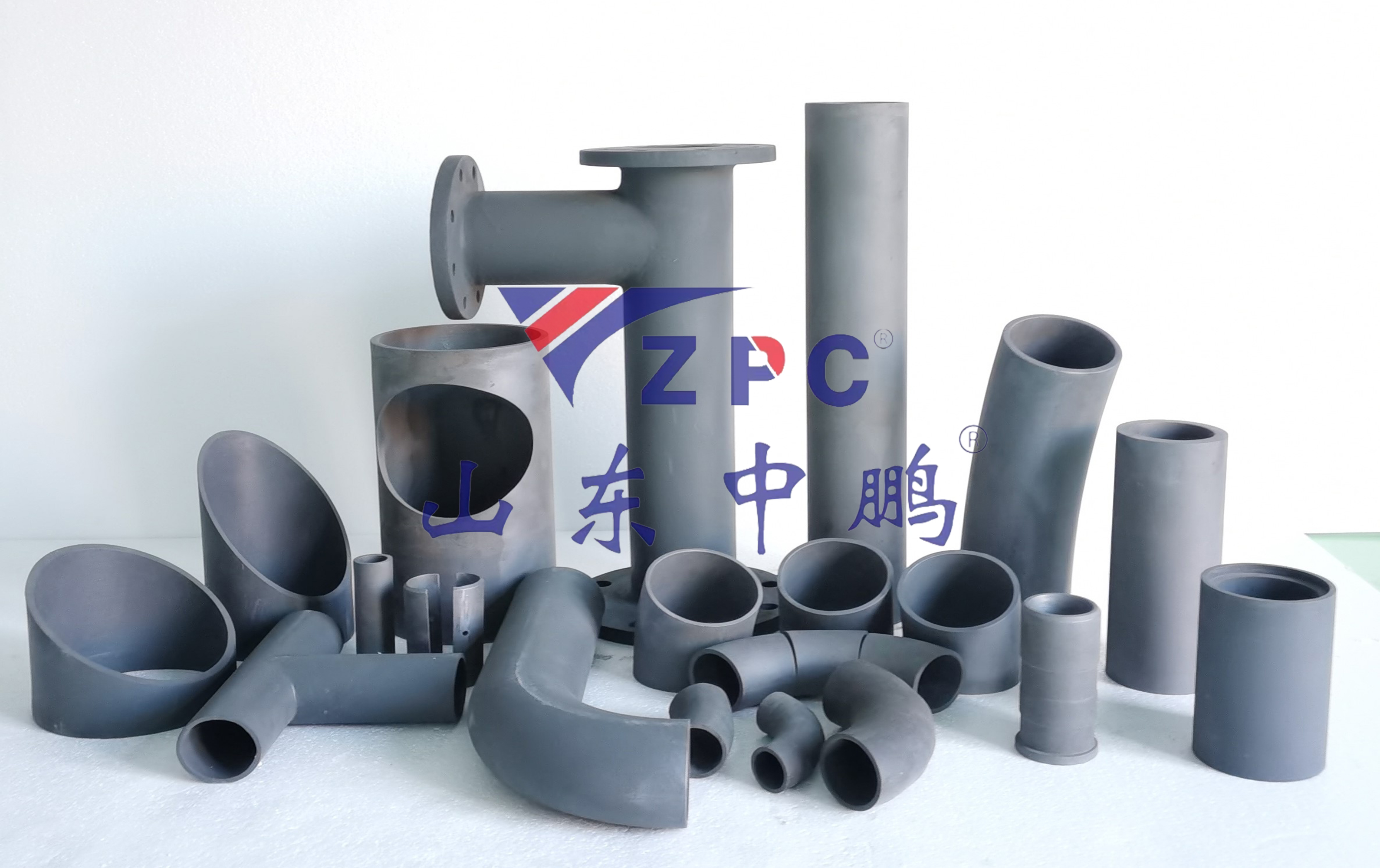

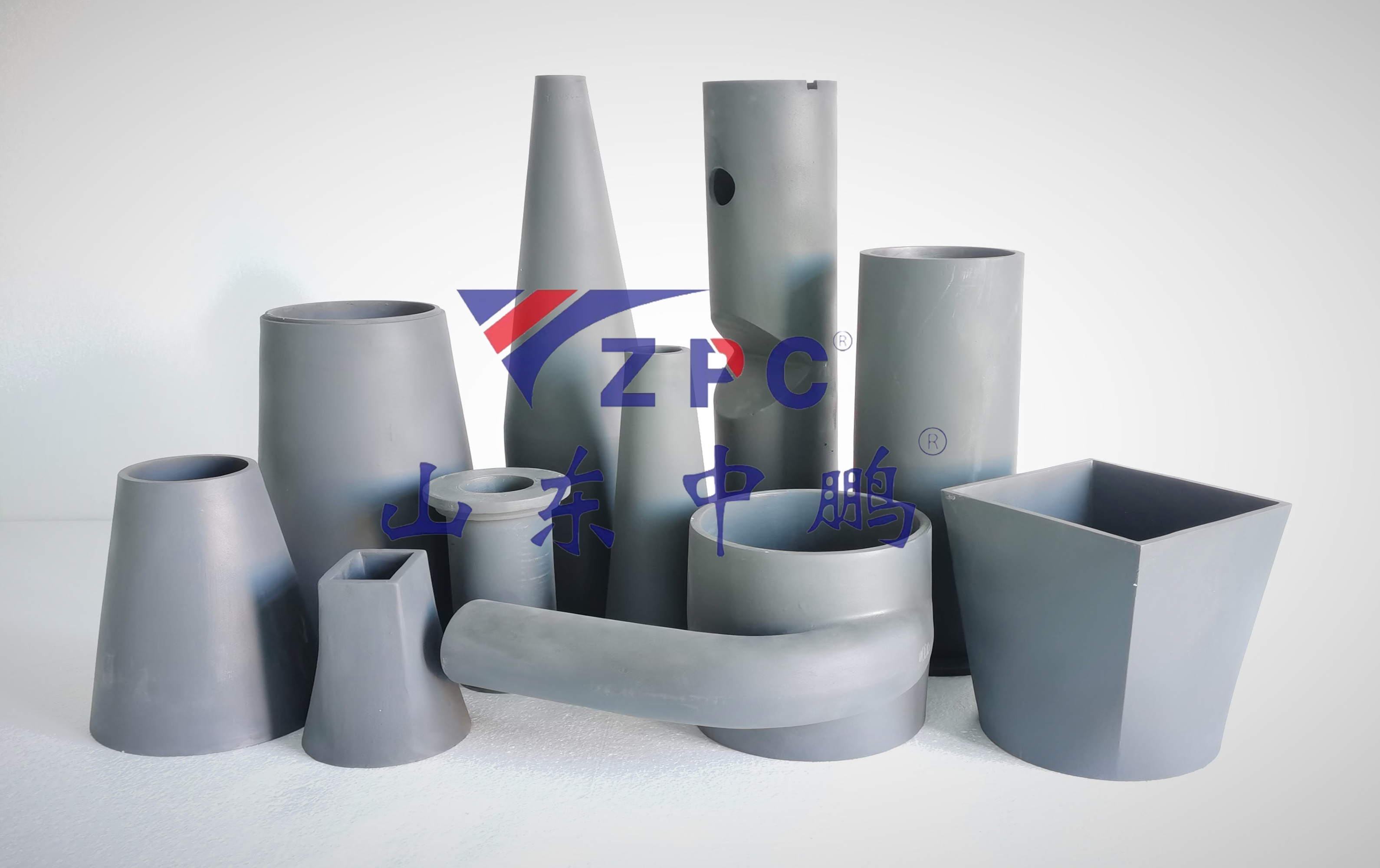

In many factories, some key equipment, such as fan casings, chutes, elbows, pump body mouth rings, etc., are often quickly worn out due to the erosion of high-speed solid containing fluids. Although these ‘easy to wear points’ are not significant, they directly affect the operational ...Read more »

-

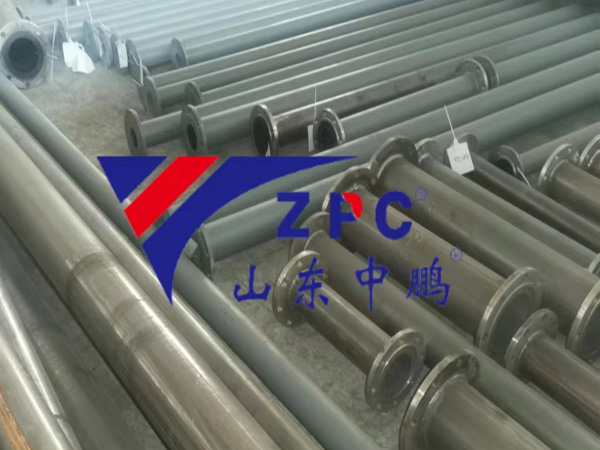

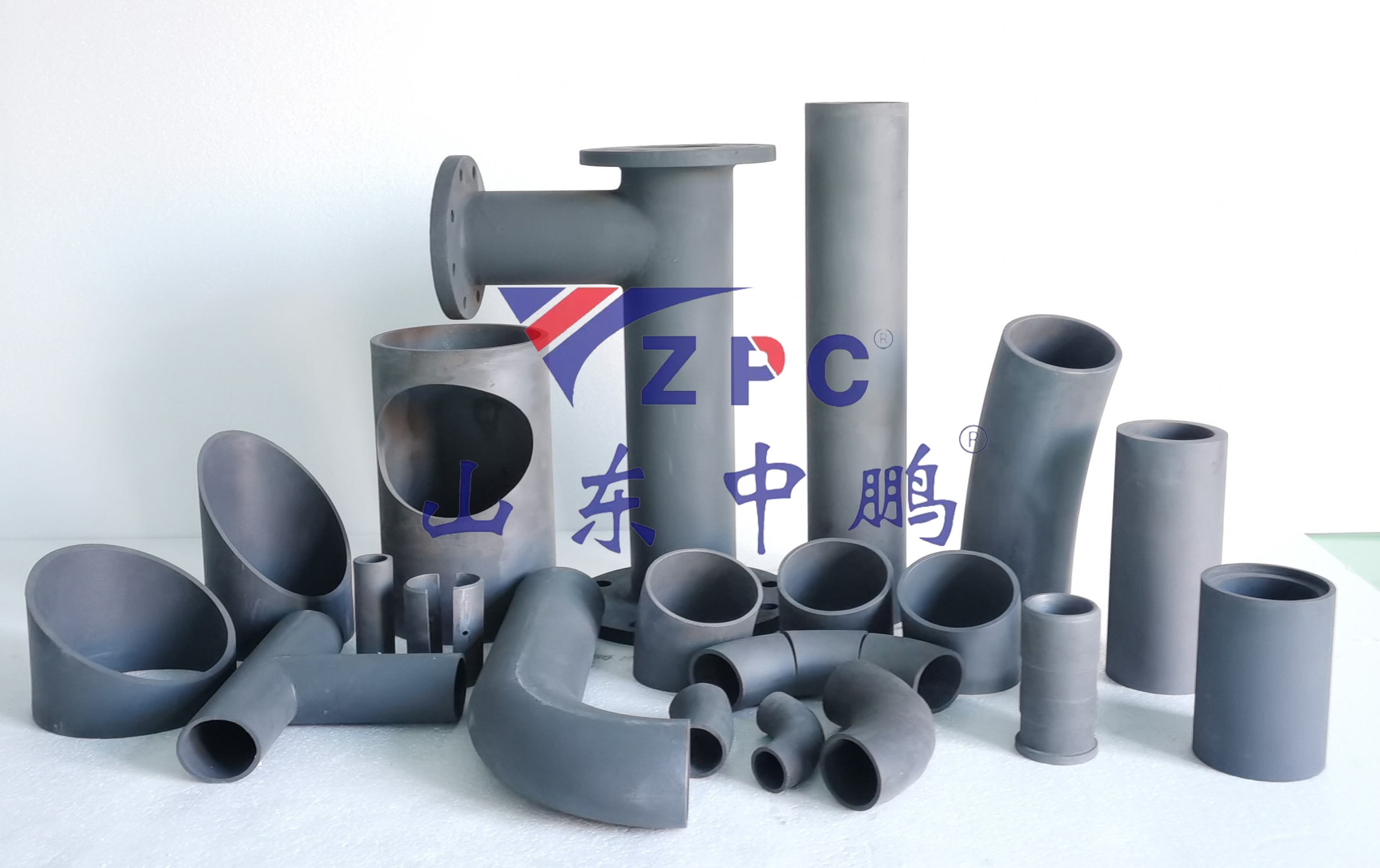

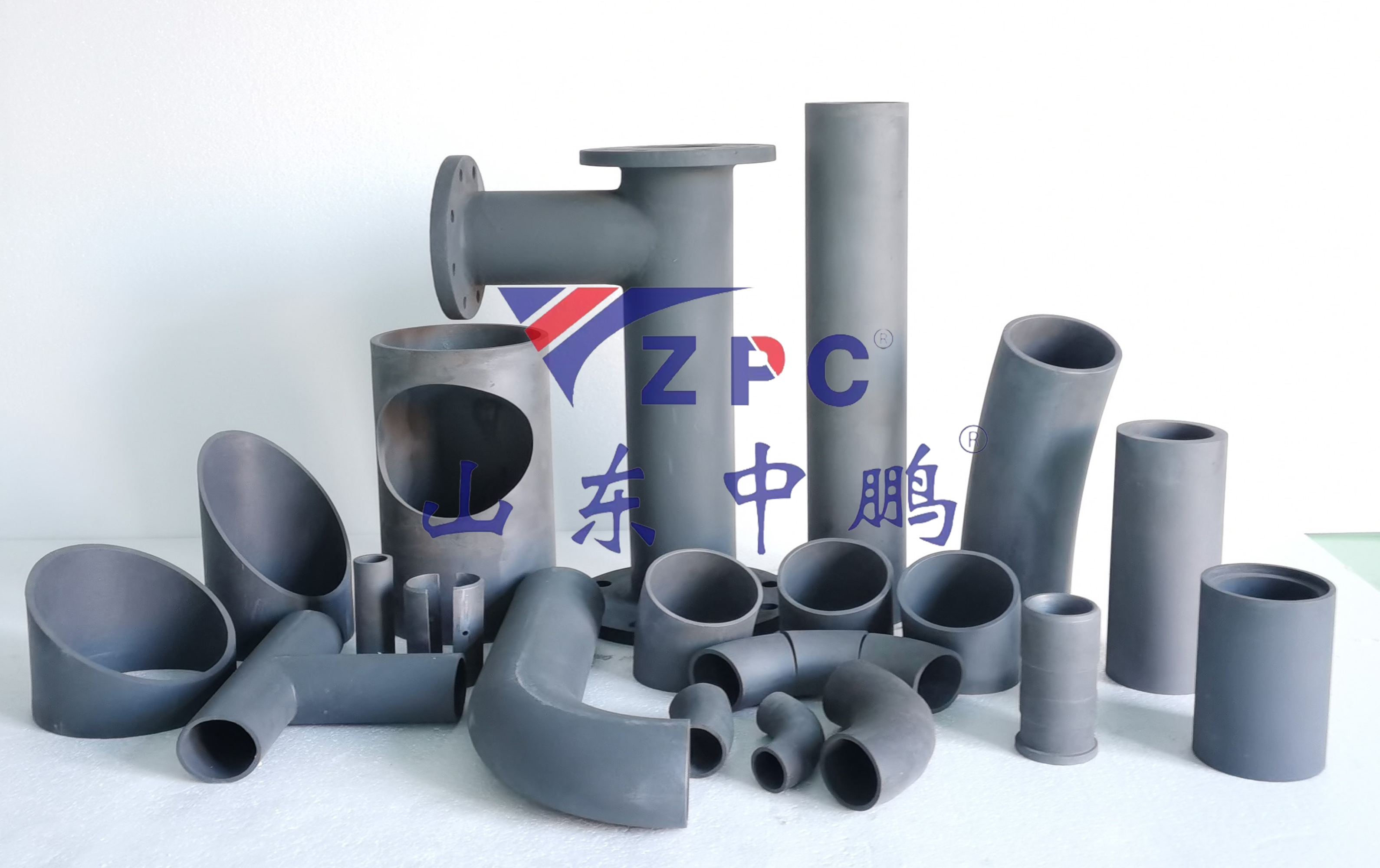

In many factories, some pipelines silently endure the harshest working conditions: high temperature, strong corrosion, and high wear. They are the ‘industrial blood vessels’ that ensure continuous and stable production. Today we are going to talk about the outstanding one in this type...Read more »

-

In the fields of mineral processing, chemical engineering, environmental protection, etc., cyclones are key equipment for achieving solid-liquid separation, classification, and concentration. Its core principle is simple: by generating centrifugal force through high-speed rotation, substances wit...Read more »

-

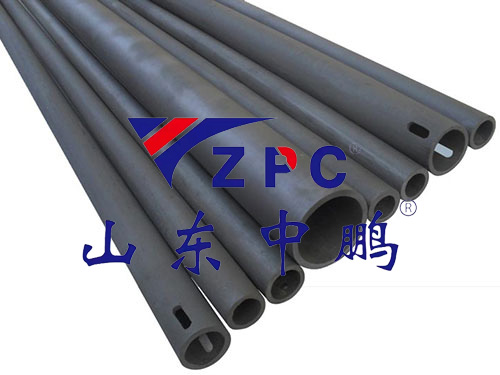

In many high-temperature kilns, the real heat source is not an open flame, but rather a series of quietly heating pipes. They are like the “invisible sun” in a kiln, uniformly heating the workpiece through thermal radiation, which is the radiation tube. Today we are going to talk abou...Read more »

-

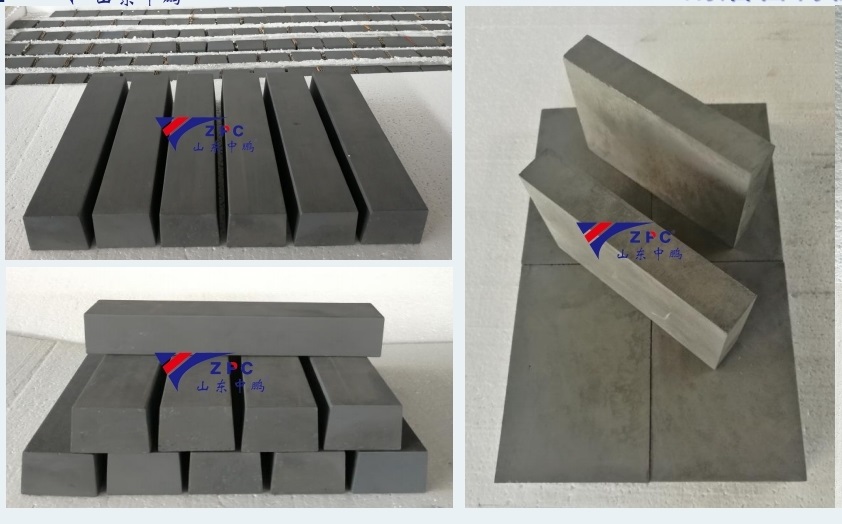

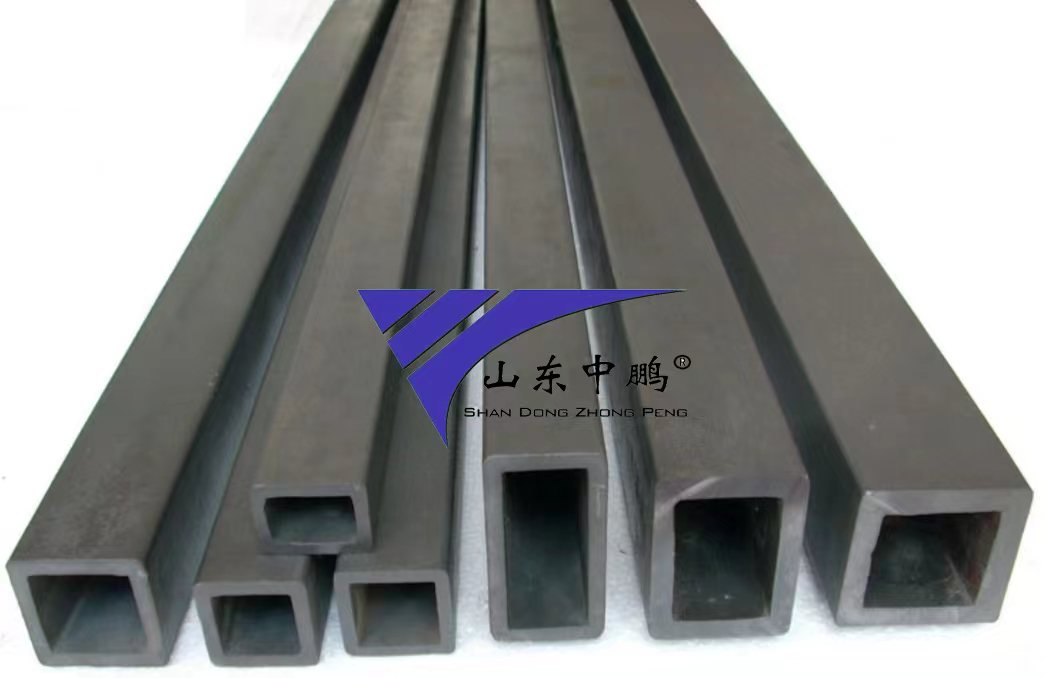

In high-temperature kilns in industries such as ceramics and glass, there is a type of key component that silently withstands the test of fire, and it is the silicon carbide square beam. Simply put, it is like the “backbone” of a kiln, responsible for supporting kiln equipment and wor...Read more »

-

In industrial production, “desulfurization” is a key link in safeguarding air quality – it can effectively remove sulfides from flue gas and reduce pollutant emissions. In the desulfurization system, there is a seemingly inconspicuous but crucial core component, which is the des...Read more »

-

In many industrial production scenarios, there are always some “unknown but crucial” components, and the silicon carbide bottom outlet is one of them. It is not as eye-catching as large equipment, but it plays the role of a “gatekeeper” in material conveying, solid-liquid ...Read more »

-

Heating is a fundamental but crucial step in many aspects of industrial production. From metal heat treatment to ceramic sintering, and even the processing of certain special materials, stable, efficient, and adaptable heating equipment is required. In these scenarios with strict requirements for...Read more »

-

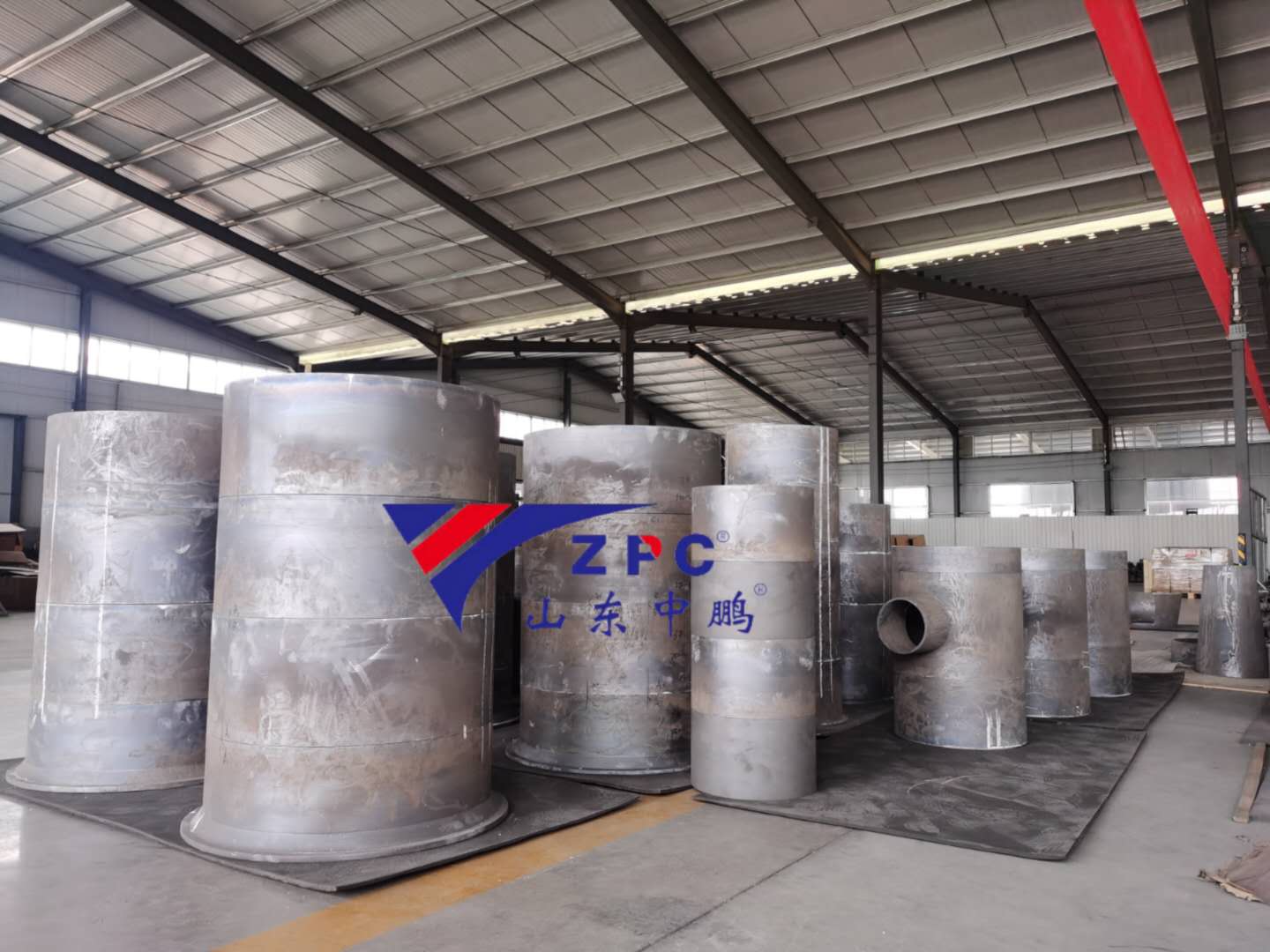

On the production line of the factory, there are always some equipment that “carries heavy loads” – such as pipelines for transporting ore and tanks for mixing materials, which have to deal with high-speed flowing particles and hard raw materials every day. These materials are l...Read more »

-

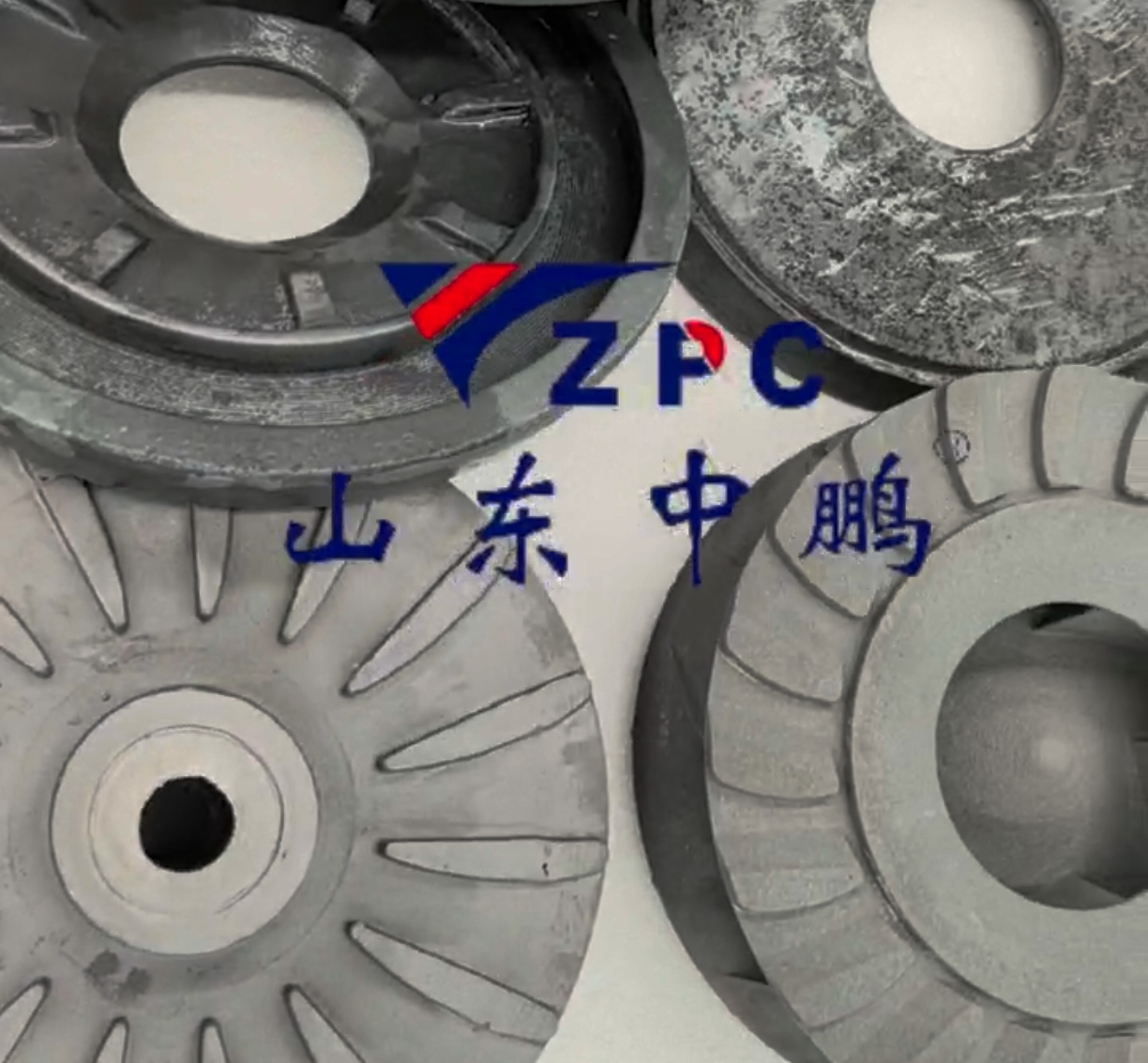

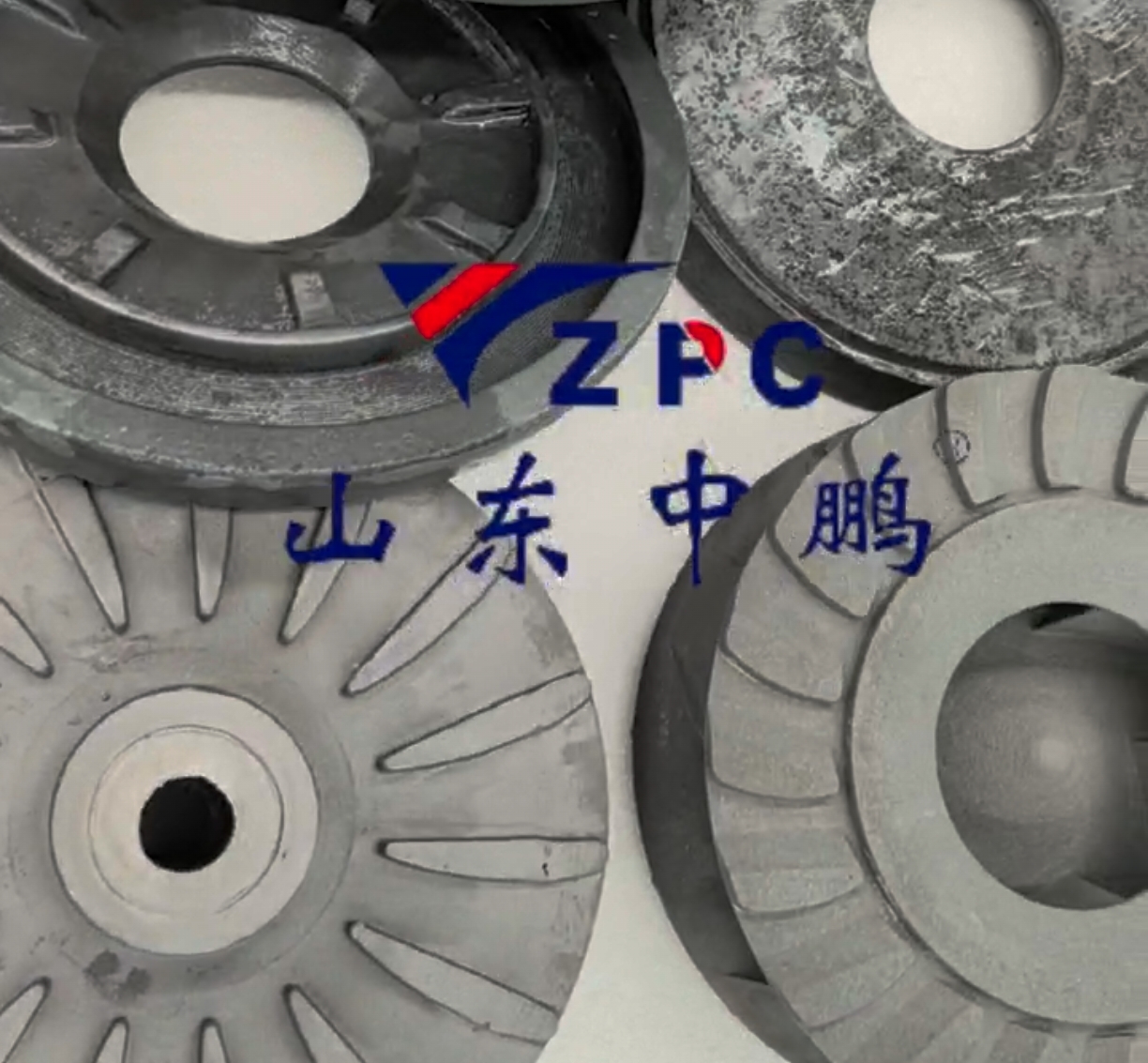

In factory production, there are always some “difficult to handle” liquids – such as mineral slurry mixed with ore particles, wastewater with sediment, these coarse and ground “slurries” that can be worn out by ordinary water pumps after only a few pumps. At this poi...Read more »

-

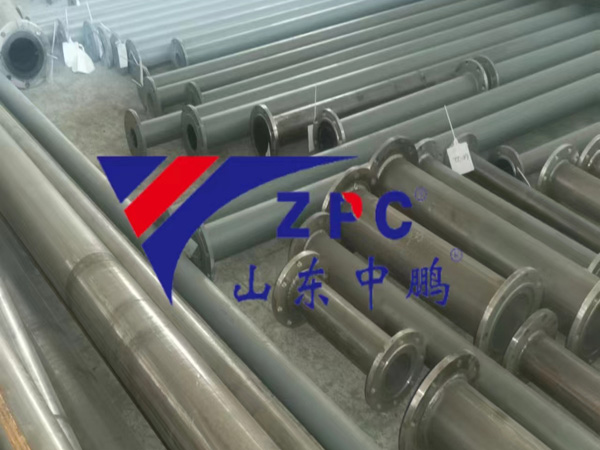

In industrial production, pipelines are like “blood vessels” transporting highly abrasive materials such as ore, coal powder, and mud. Over time, the inner walls of ordinary pipelines are easily worn thin and perforated, requiring frequent replacement and potentially affecting product...Read more »

-

Behind the technological breakthroughs in faster charging of new energy vehicles and more efficient aviation engines, there is a seemingly ordinary but powerful material – silicon carbide ceramics. This advanced ceramic composed of carbon and silicon elements, although not as commonly discu...Read more »

-

In the family of materials science, silicon carbide ceramics have gradually emerged as a “hot commodity” in multiple industrial fields due to their unique properties. Today, let’s step into the world of silicon carbide ceramics and see where it excels. Aerospace: Pursuit of Ligh...Read more »

-

When it comes to “ceramics”, many people first think of household dishes, decorative vases – fragile and delicate, seemingly unrelated to “industry” or “hardcore”. But there is a type of ceramic that breaks this inherent impression. Its hardness is second...Read more »

-

In the scenarios of factory workshops, mining, or power transmission, there is a type of pipeline that is “unknown” all year round but carries heavy responsibilities – they often transport media with strong abrasion properties such as sand, slurry, coal powder, etc. Ordinary pip...Read more »

-

Behind the scenes of industrial production, there are always some “unknown” equipment supporting the smooth operation of the entire production line, and the silicon carbide slurry pump is one of them. It may not be as eye-catching as precision instruments, but with its unique performa...Read more »

-

In the close relationship between industrial production and environmental protection, there are many seemingly insignificant but crucial equipment, and the silicon carbide desulfurization nozzle is one of them. It silently guards our blue sky and is an indispensable “behind the scenes hero&...Read more »

-

In the corners of factory workshops and mining transportation, there is a crucial but easily overlooked “role” – the conveying pipeline. They transport minerals, mortar, and chemical raw materials day after day, and their inner walls are constantly subjected to friction and impa...Read more »

-

In industrial scenarios such as mining and chemical engineering, cyclones are the core equipment for efficiently completing material classification. The key to determining its “combat effectiveness” is often hidden in the inconspicuous inner lining – it directly bears the erosi...Read more »

-

In industrial production, pipelines are like “blood vessels” responsible for transporting various media such as ore slurry, fly ash, and chemical raw materials. But these media often carry particles and are corrosive. Ordinary pipelines will soon be worn through and corroded, requirin...Read more »

-

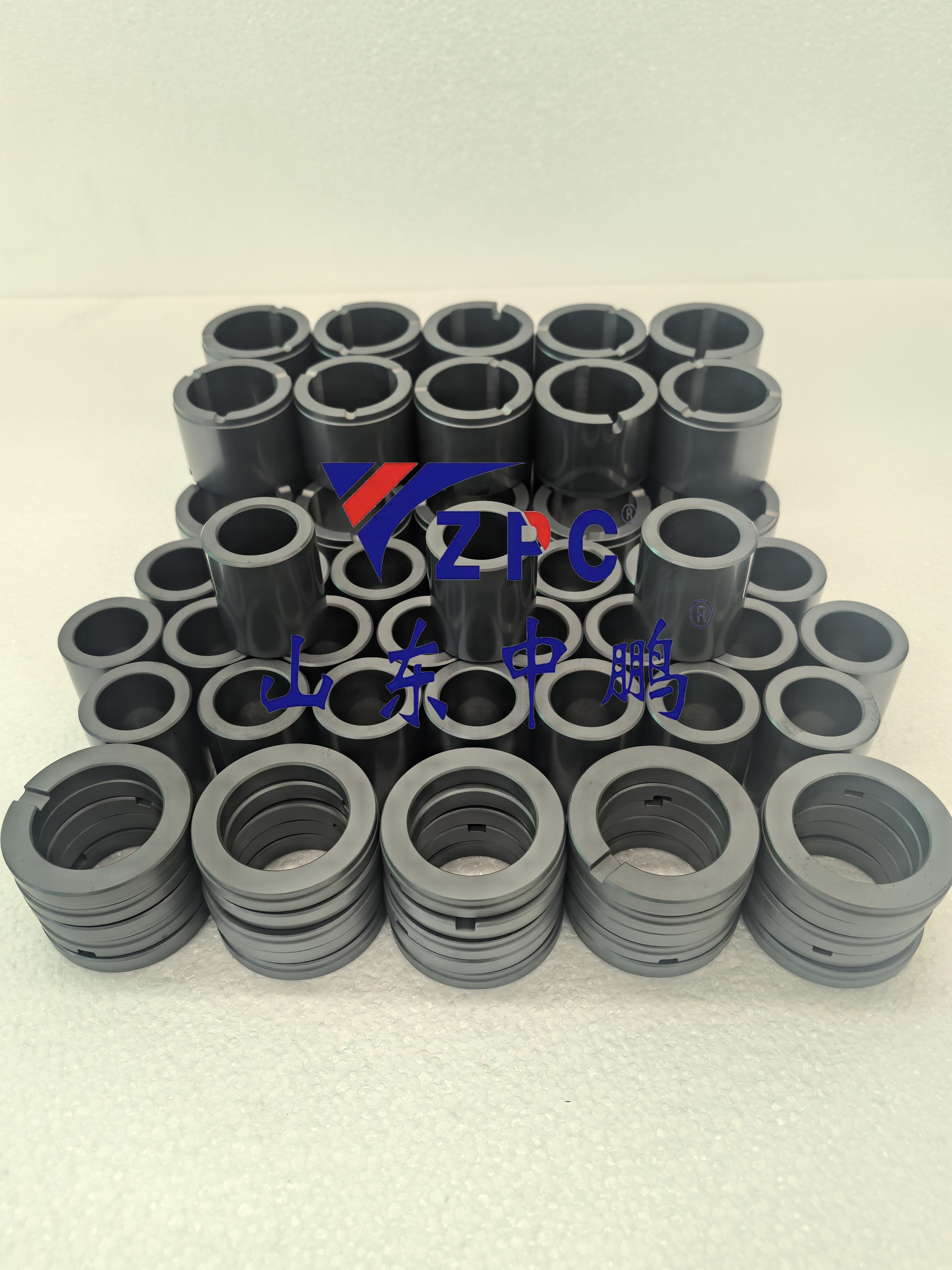

In the operation of industrial equipment, there is an easily overlooked but crucial component – the seal. It is like the “sealing ring” of a device, responsible for isolating internal fluids and gases, preventing leaks. Once the seal fails, it can affect the efficiency of the de...Read more »

-

Silicon carbide (SiC) ceramics have become the core material in the field of high-temperature structural ceramics due to their low thermal expansion coefficient, high thermal conductivity, high hardness, and excellent thermal and chemical stability. They are widely used in key fields such as aero...Read more »