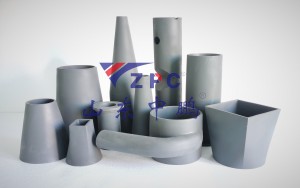

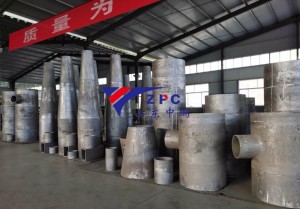

In the field of industrial separation processes, hydrocyclones play a key role in efficiently separating particles from liquids. Among the various materials used to manufacture hydrocyclones, silicon carbide ceramics are the first choice due to their excellent performance. This article takes an in-depth look at the advantages of silicon carbide ceramic hydrocyclones, focusing on their wear resistance, corrosion resistance and high thermal stability, which make them an ideal solution for a variety of industrial applications.

Excellent wear resistance

One of the most significant advantages of silicon carbide ceramic hydrocyclones is their superior wear resistance. Silicon carbide is known for its extremely high hardness, providing a strong lining for the hydrocyclone that can withstand the rigors of high-speed rotation and friction. In industries that process abrasive materials such as mining, mineral processing and wastewater treatment, wear and tear on equipment can lead to frequent maintenance and replacement costs. However, the use of silicon carbide ceramics can significantly extend the service life of the hydrocyclone, reduce downtime and improve operational efficiency.

The hardness of silicon carbide enables it to resist the erosive effects of solid particles suspended in the liquid. This property is particularly beneficial in applications where hydrocyclones are constantly subject to abrasive wear. As a result, companies can achieve higher production rates without having to worry about equipment failure, ultimately increasing productivity and profitability.

Excellent corrosion resistance

Another compelling benefit of silicon carbide ceramic hydrocyclones is their superior corrosion resistance. Silicon carbide exhibits excellent resistance to a wide range of chemicals, making it suitable for handling corrosive substances commonly found in a variety of industrial processes. Industries such as chemical manufacturing, oil and gas, and wastewater treatment often deal with corrosive chemicals that can degrade traditional materials over time.

Silicon carbide’s corrosion resistance ensures that hydrocyclone linings remain intact and functional even in harsh environments. This durability means longer equipment life, reducing the need for frequent replacement and maintenance. Additionally, the ability to handle corrosive materials without compromising performance enables companies to expand their operational capabilities and tackle more challenging applications.

High thermal stability

In addition to being wear and corrosion resistant, silicon carbide ceramic hydrocyclones also have high thermal stability. This property is critical for applications involving high temperature processes where conventional materials may fail or degrade. Silicon carbide maintains stable performance even under extreme temperature conditions, ensuring that the hydrocyclone operates efficiently without compromising its structural integrity.

Silicon carbide’s high thermal stability allows hydrocyclones to be used in a variety of applications, including those involving hot liquids or slurries. This versatility is particularly beneficial in industries such as petrochemical and power generation where temperature fluctuations are common. By using silicon carbide ceramic hydrocyclones, companies can ensure consistent performance and reliability even in the most demanding environments.

Improve operational efficiency

The combination of wear resistance, corrosion resistance and high thermal stability helps improve the operating efficiency of industrial processes. Silicon carbide ceramic hydrocyclones can operate for long periods of time without maintenance or replacement, allowing companies to maximize production capacity. This efficiency not only reduces operating costs, but also minimizes the environmental impact associated with equipment disposal and replacement.

Additionally, the ability of silicon carbide ceramic hydrocyclones to handle a wide range of materials and conditions makes them a versatile choice for a wide range of industries. Whether handling abrasive slurries, corrosive chemicals or high temperature processes, these hydrocyclones can adapt to the specific needs of the application, providing reliable and efficient separation.

Cost-effectiveness

While the initial investment in silicon carbide ceramic hydrocyclones may be higher than traditional materials, the long-term cost benefits cannot be ignored. The durability and longevity of silicon carbide means that companies can save significantly on maintenance and replacement costs over time. In addition, improvements in operational efficiency can increase productivity, further justifying the investment.

In an industry where downtime can result in significant financial losses, the reliability of silicon carbide ceramic hydrocyclones becomes even more important. By minimizing the risk of equipment failure and ensuring consistent performance, companies can maintain production schedules and meet customer needs without interruption.

Environmental Benefits

The use of silicon carbide ceramic hydrocyclones also complies with growing environmental concerns in industrial operations. The extended service life of these hydrocyclones reduces the frequency of replacement, thereby reducing waste generated by obsolete equipment. In addition, the ability to handle corrosive materials without degradation minimizes the risk of chemical leaks and environmental contamination.

By investing in durable and efficient equipment, such as silicon carbide ceramic cyclones, companies can demonstrate their commitment to sustainability and responsible resource management. This not only enhances their reputation, but also positions them well in an increasingly environmentally conscious market.

In summary, silicon carbide ceramic hydrocyclones offer a variety of advantages and are an excellent choice for a variety of industrial applications. Their outstanding wear resistance, excellent corrosion resistance, and high thermal stability ensure reliable performance in challenging environments. In addition, enhanced operational efficiency and long-term cost-effectiveness make them widely used in industries ranging from mining to chemical processing.

As industries continue to seek innovative solutions to improve productivity and sustainability, silicon carbide ceramic hydrocyclones stand out as a rugged and reliable choice. By leveraging the unique properties of silicon carbide, companies can optimize their separation processes, reduce maintenance costs, and ultimately achieve greater success in their operations.

Post time: Mar-25-2025