-

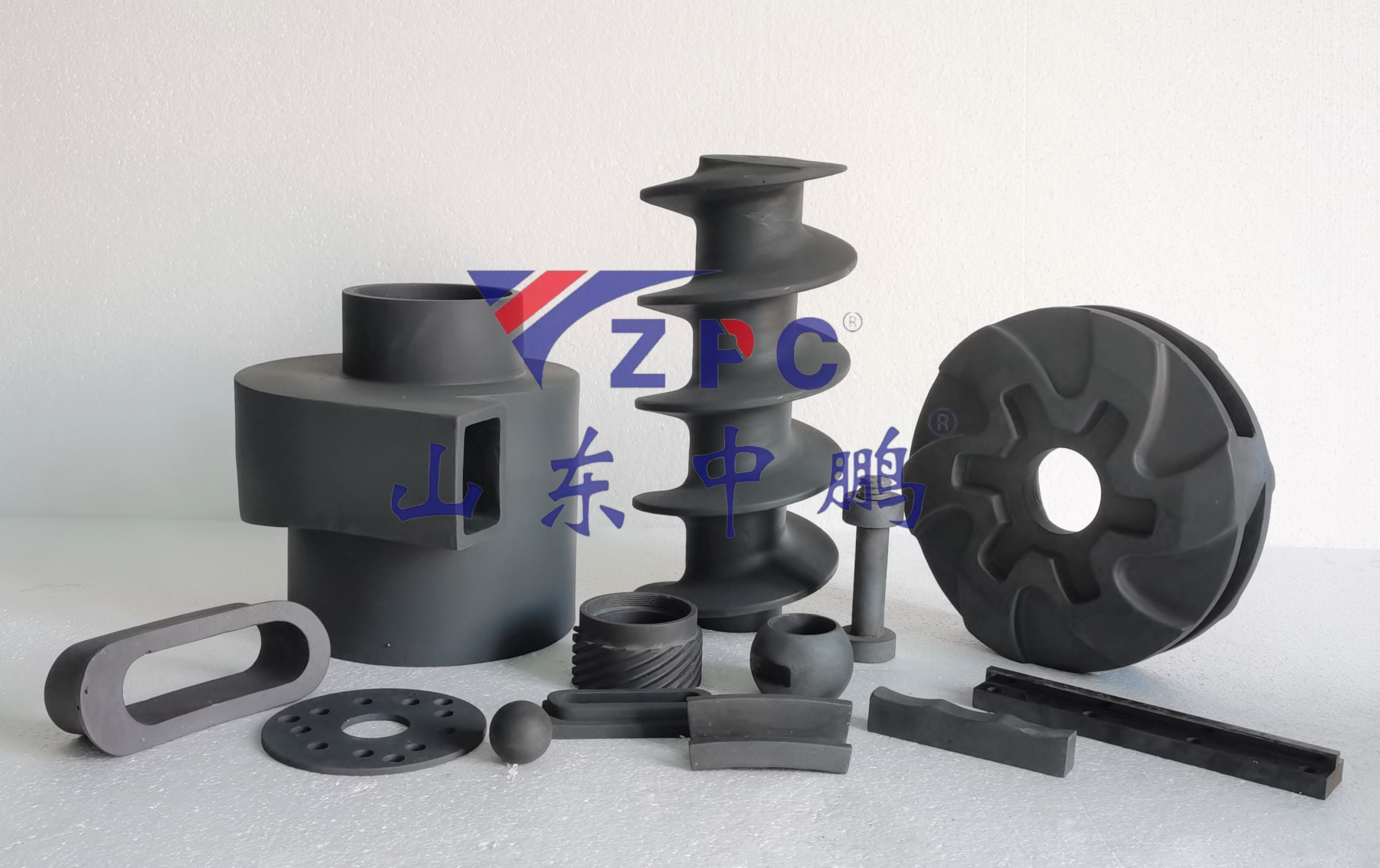

Entering the modern industrial world, one can always see the presence of a special type of material – they are neither as shiny as metals nor as light as plastics, but they silently support the operation of modern industry. This is the industrial ceramics family, a group of inorganic non-me...Read more »

-

In cutting-edge fields such as semiconductors, new energy, and aerospace, a grayish-black ceramic material is quietly playing a key role. It is silicon carbide ceramic – a material with a hardness comparable to that of diamond, which is changing the face of modern industry precisely because...Read more »

-

In the long dialogue between humans and protective materials, silicon carbide ceramics is responding to the eternal proposition of safety protection with a unique voice. This seemingly ordinary gray-black ceramic is performing a modern version of the story of “flexing with softness against ...Read more »

-

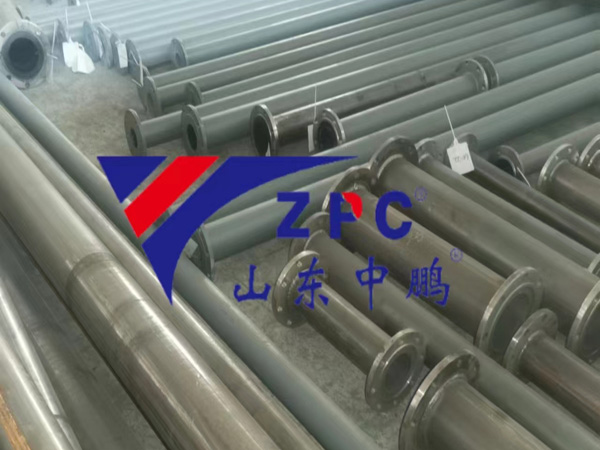

Deep in the mine, when the mineral sand rushes in the pipeline at a very high speed, ordinary steel pipes are often worn through in less than half a year. The frequent damage of these “metal blood vessels” not only causes resource waste, but also may lead to production accidents. Nowa...Read more »

-

In the field of modern industrial materials, zirconia ceramics and silicon carbide ceramics are both high-performance materials that have attracted much attention. However, there are significant differences in their characteristics, especially in extreme environments such as high temperature, wea...Read more »

-

In today’s booming new energy industry, industrial ceramics, with their unique performance advantages, are becoming a key material driving technological innovation. From photovoltaic power generation to lithium battery manufacturing, and then to hydrogen energy utilization, this seemingly o...Read more »

-

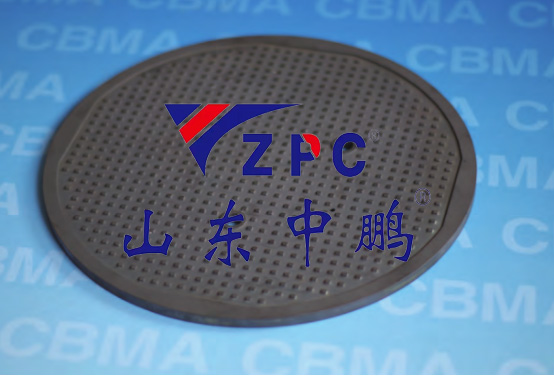

In modern industry, efficient, environmentally friendly, and durable materials are increasingly being valued. Silicon carbide microporous ceramics, as a high-performance porous material, are playing an important role in fields such as high-temperature filtration, environmental protection, and pre...Read more »

-

In the high-temperature furnace that continues to operate in the metallurgical workshop, a ceramic component is silently enduring the scorching heat; In the flue gas desulfurization system, a ceramic nozzle is resisting the corrosion test of strong acid and alkali. The ‘unsung heroes’...Read more »

-

From transportation pipelines to new energy vehicles, from high-temperature kilns to aerospace satellites, a material known as the “industrial diamond” is quietly rewriting the boundaries of modern manufacturing. Silicon carbide ceramics, a superhard material with a hardness second on...Read more »

-

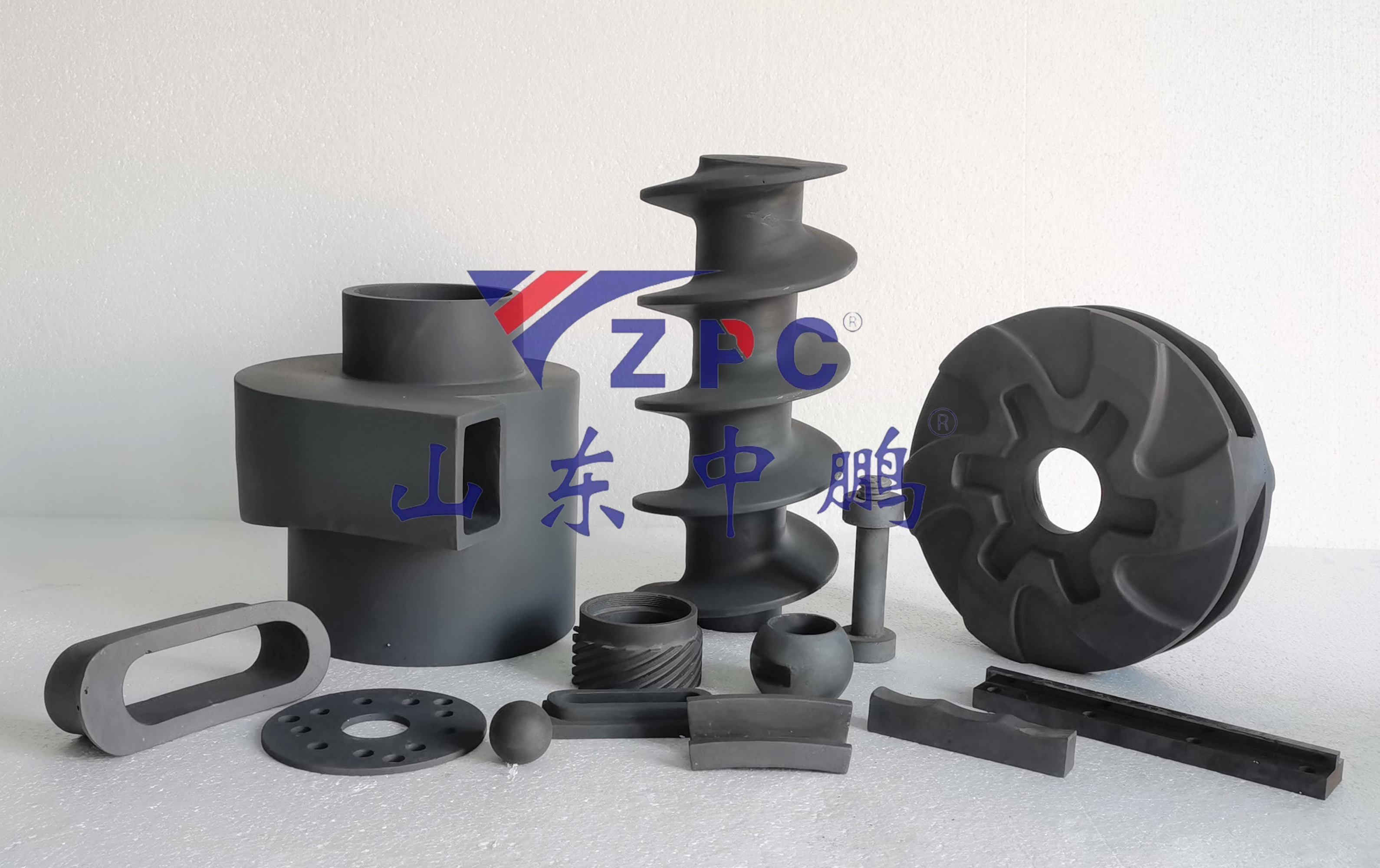

Beside the scorching furnace in the steel plant, by the churning acid pool in the chemical plant, and in the core components of high-speed precision machinery, a seemingly ordinary gray black ceramic is quietly refreshing human understanding of material properties. Silicon carbide ceramics –...Read more »

-

In the clean room of the semiconductor factory, black wafers shining with metallic luster are being precision processed one by one; In the combustion chamber of the spacecraft engine, a special ceramic component is undergoing a 2000 ℃ flame baptism. Behind these scenes, there is an active materia...Read more »

-

Industrial expert in upgrading pipelines’ hard core ‘- exploring silicon carbide wear-resistant tees

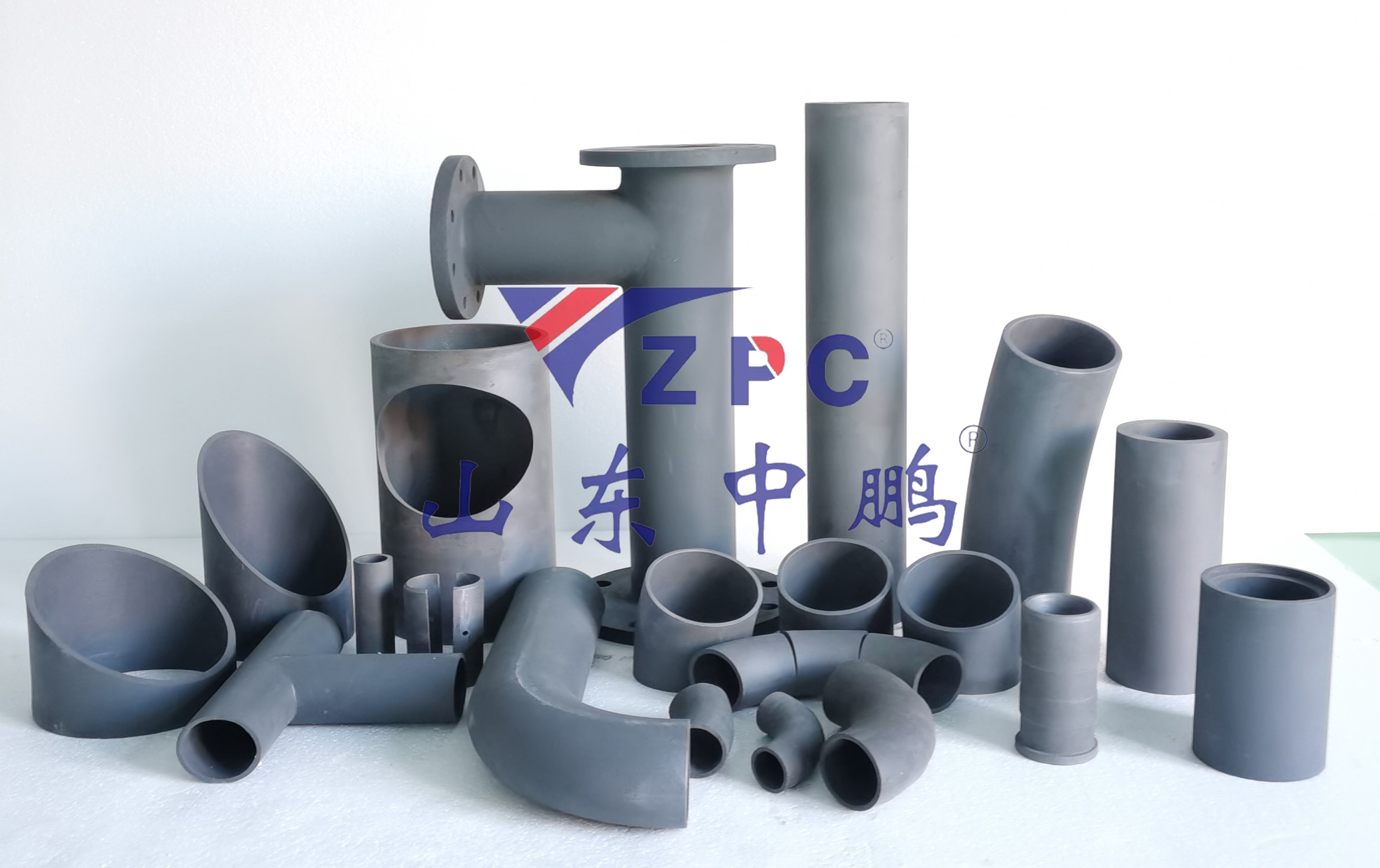

Industrial expert in upgrading pipelines’ hard core ‘- exploring silicon carbide wear-resistant teesIn industrial fields such as mining, electricity, and chemical engineering, pipeline systems are like the “vascular network” of the human body, undertaking the important mission of transporting various media. The three-way components in the pipeline, like the “traffic hub”...Read more »

-

In lithography machines for chip manufacturing, an invisible error can destroy wafers worth millions of dollars. Every micrometer of displacement here is crucial to the success or failure of nanoscale circuits, and the core that supports this precision dance is our protagonist today: silicon carb...Read more »

-

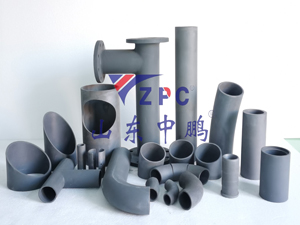

In industrial production, conveying pipelines are like blood vessels, carrying the flow of materials such as ore, slag, and high-temperature slurry. However, in the harsh environment of high-speed flow, high temperature and pressure, and strong corrosion, traditional pipelines often face the prob...Read more »

-

The lungs of industrial giants such as steel mills and power plants inhale and exhale tens of thousands of tons of smoke every day – how to make these industrial waste gases “spit out” cleaner air? An efficient desulfurization system is like a purifier, and the silicon carbide f...Read more »

-

In the flames leaping in high-temperature environments and on the temperature curve of metal heat treatment, a new industrial “fire control system” is reshaping high-temperature manufacturing processes – the silicon carbide nozzle, with its precise control ability and excellent ...Read more »

-

In the industrial scene where high temperature, corrosion, and wear coexist, the dilemma of frequent replacement of traditional metal pipelines is being broken by a new material pipeline – silicon carbide wear-resistant pipelines, with their unique material properties, have sparked a techno...Read more »

-

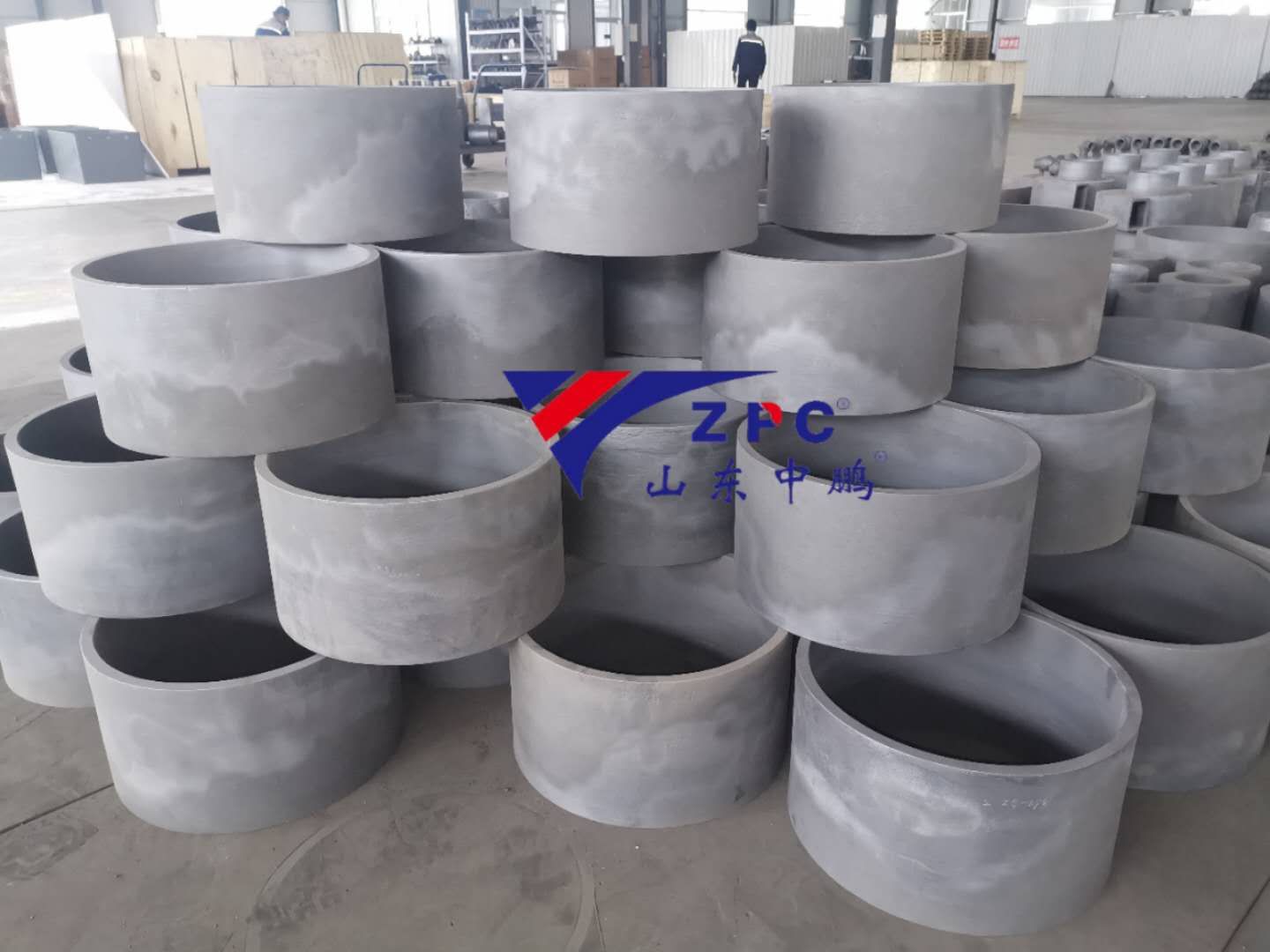

In a certain high-temperature kiln, when the temperature inside the furnace exceeds 1200 ℃, traditional metal materials are approaching the melting critical point, while our silicon carbide radiation tube is transmitting surging energy with stable thermal radiation – this is a microcosm of ...Read more »

-

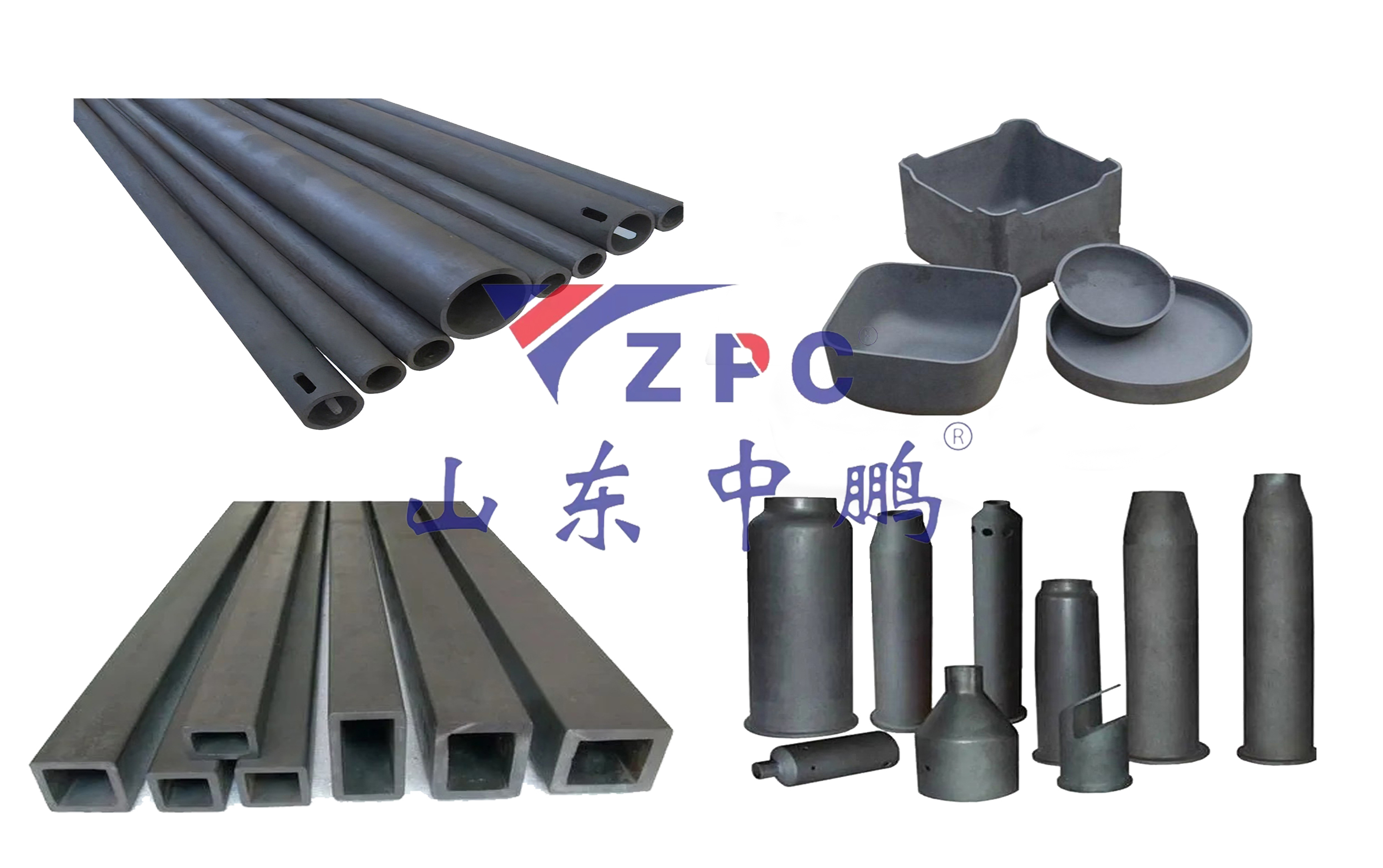

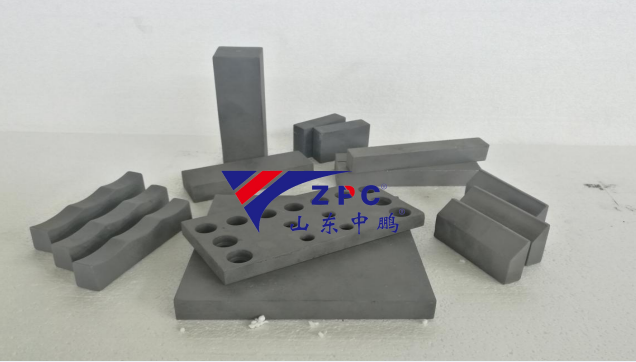

Silicon carbide ceramics are a key material in a wide range of industries due to their unique properties, including high hardness, low density and excellent heat resistance. These properties make silicon carbide (SiC) an ideal choice for applications in mechanical engineering, chemical and metall...Read more »

-

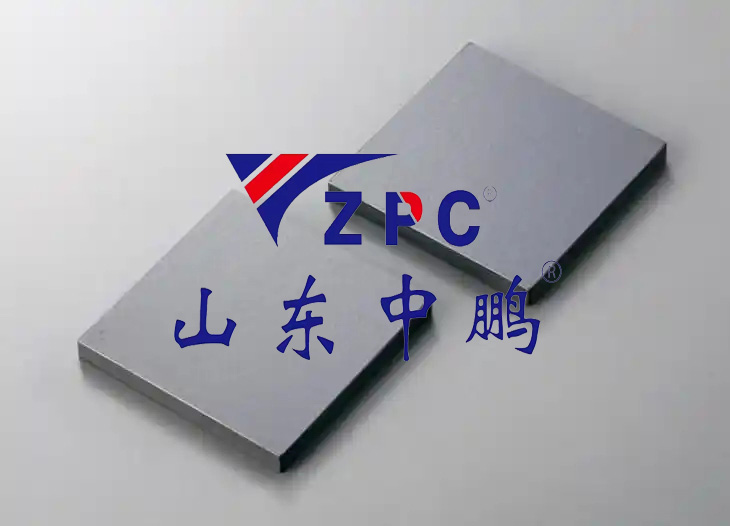

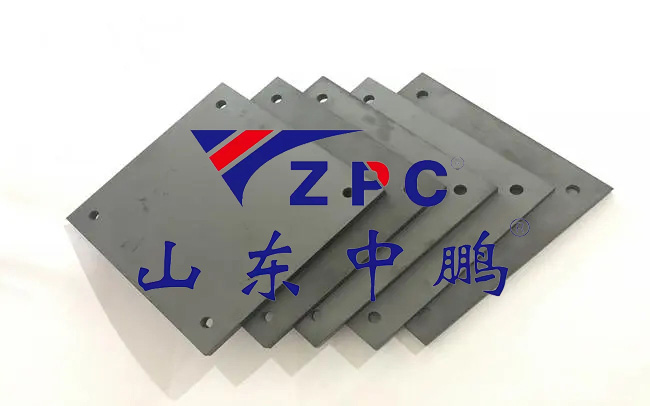

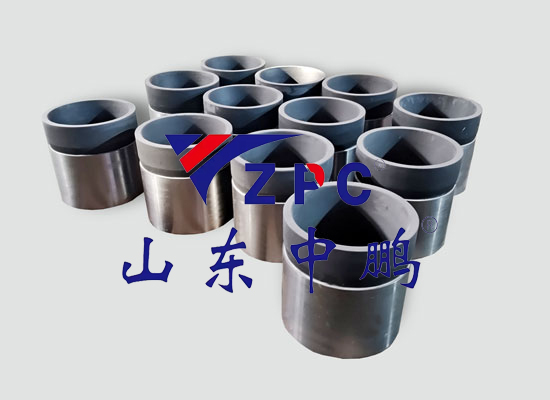

In industries grappling with abrasive materials, extreme temperatures, and corrosive media, wear resistant silicon carbide liners have become indispensable for enhancing equipment longevity and operational efficiency. Crafted from reaction-bonded silicon carbide (RB-SiC), these liners merge excep...Read more »

-

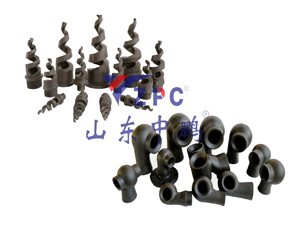

In the world of industrial production, the importance of desulfurization cannot be overstated. It plays a key role in environmental protection and sustainable development, ensuring that harmful emissions are minimized and strict regulations are adhered to. At the heart of this critical process ar...Read more »

-

In the field of industrial heating solutions, silicon carbide radiant tubes have become a frontrunner, gaining attention for their superior performance and reliability. This innovative product is designed to withstand extreme temperatures, making it ideal for a variety of applications, including ...Read more »

-

Silicon carbide (SiC) is a material of choice in a variety of industrial applications due to its outstanding hardness, thermal stability, and chemical resistance. Among its many forms, silicon carbide tubes are particularly valued for their durability and performance in harsh environments. This ...Read more »

-

Silicon carbide (SiC) ceramic nozzles have become key components in a variety of industrial applications, especially in the field of flue gas desulfurization (FGD). These nozzles are carefully designed to withstand extreme conditions and are well suited to environments where high temperatures an...Read more »

-

Silicon carbide tubes have become a revolutionary solution for a wide range of industries due to their superior properties. This advanced material features high strength, high hardness, good wear resistance, high temperature resistance, and corrosion resistance. These properties make silicon car...Read more »