New Delivery for Silicon Carbide Plates - Silicon carbide Flue Gas Desulphurization Spray nozzle factory/manufacturer – ZhongPeng

New Delivery for Silicon Carbide Plates - Silicon carbide Flue Gas Desulphurization Spray nozzle factory/manufacturer – ZhongPeng Detail:

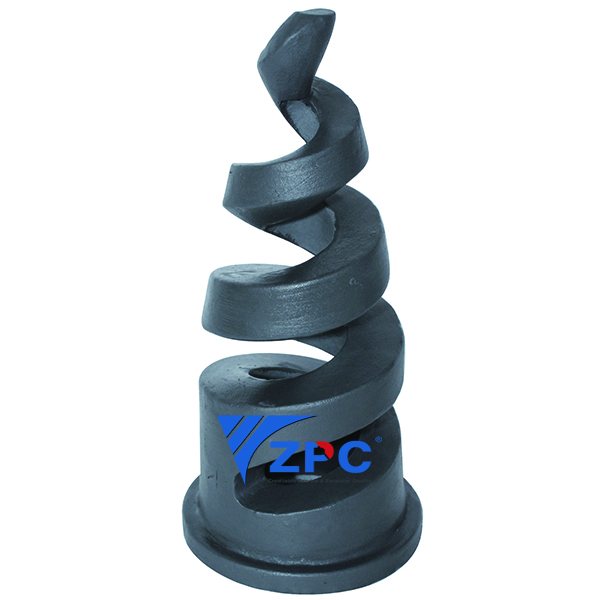

Flue Gas Desulfurization (FGD) Absorber Nozzles

Removal of Sulfur Oxides (SOx) is the product from an exhaust gases using an alkali reagent, such as a wet limestone slurry.

When fossil fuels are utilized in combustion processes to run boilers, furnaces, or other equipment which can release SO2 or SO3 as part of the exhaust gas. These sulfur oxides react easily with other elements to form harmful compound such as sulfuric acid. They have the potential to negatively affect human health and the environment. Due to potential effects, the compound control in flue gases is an essential part of coal fired power plants and other industrial applications.

Due to erosion, plugging, and build-up concerns, one of the most reliable systems to control these emissions is an open-tower wet flue gas desulfurization (FGD) process using a limestone, hydrated lime, seawater, or other alkaline solution. Spray nozzles are able to effectively and reliably distribute these slurries into absorption towers. By creating uniform patterns of properly sized droplets, these nozzles are able to effectively create the surface area needed for proper absorption while minimizing entrainment of the scrubbing solution into the flue gas.

Selecting an FGD Absorber Nozzle:

Important factors to consider:

Scrubbing media density and viscosity

Required droplet size

The correct droplet size is essential to ensuring proper absorption rates

Nozzle material

As the flue gas is often corrosive and the scrubbing fluid is frequently a slurry with high solids content and abrasive properties, selecting the appropriate corrosion and wear resistant material is important

Nozzle clog resistance

As the scrubbing fluid is frequently a slurry with high solids content, selection of the nozzle with regard to clog resistance is important

Nozzle spray pattern and placement

In order to ensure proper absorption complete coverage of the gas stream with no bypass and sufficient residence time is important

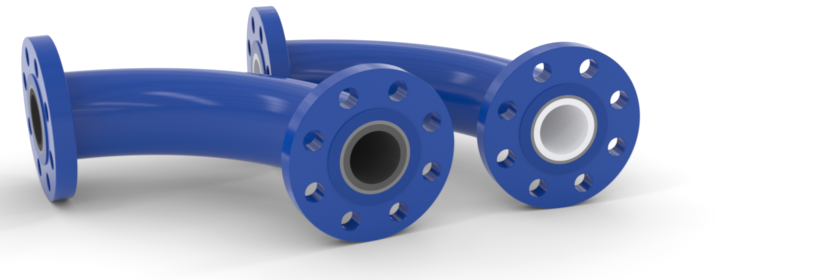

Nozzle connection size and type

Required scrubbing fluid flow rates

Available pressure drop (∆P) across the nozzle

∆P = supply pressure at nozzle inlet – process pressure outside nozzle

Our experienced engineers can help determine which nozzle will perform as required with your design details

Common FGD Absorber Nozzle Uses and Industries:

Coal and other fossil fuel power plants

Petroleum refineries

Municipal waste incinerators

Cement kilns

Metal smelters

Product detail pictures:

Related Product Guide:

Technical Ceramics

Wear resistance block, plates and inner lining

New Delivery for Silicon Carbide Plates - Silicon carbide Flue Gas Desulphurization Spray nozzle factory/manufacturer – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.