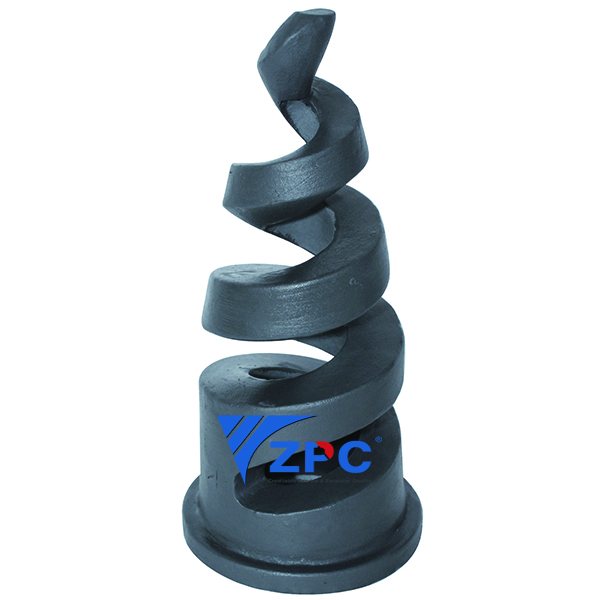

Manufacturing Companies for Silicon Carbide Spiral Nozzle - Wear-resistance-part-in-Mine – ZhongPeng

Manufacturing Companies for Silicon Carbide Spiral Nozzle - Wear-resistance-part-in-Mine – ZhongPeng Detail:

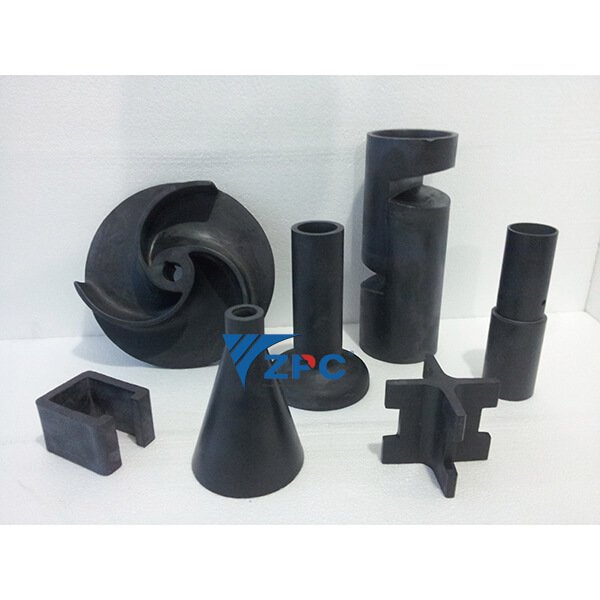

ZPC offers a range of ceramic wear liner solutions.

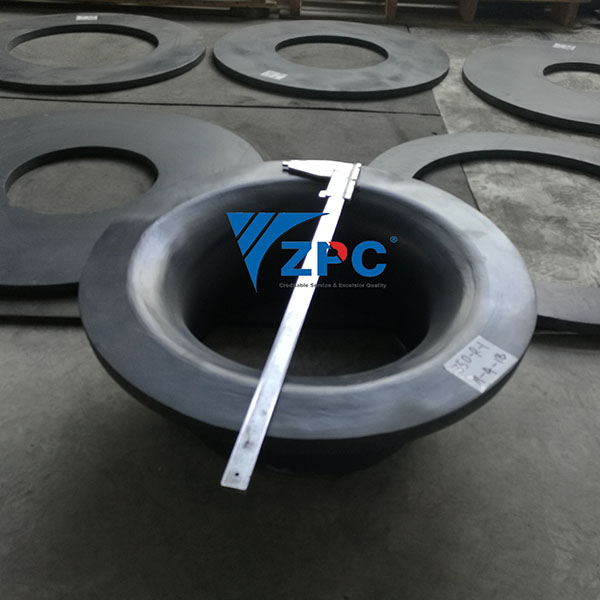

RBSiC/SiSiC Ceramic wear products offer improved wear and material flow characteristics with the added benefit of noise reduction. Ceramic wear solutions are increasingly being used in applications affected by high impact; wear from highly abrasive bulk material and material hang-up from sticky ores.

RBSiC/SiSiC: New Moh’s hardness is 13. It has the excellent resistance to erosion and corrosion, the excellent abrasion-resistance and the anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 7 to 10 times longer than alumina material. The Max-thickness of wear-resistant products can reach 45mm. RBSiC Ceramic wear products offer material handlers improved productivity (through reduced downtime and improved material flow) and a superior rate of return.

Manufactured in standard sizes or for specific customer requirements and designed to fit all appropriate applications, ceramic liners are particularly suitable for many applications within bulk material handling equipment.

Different cearamic liners for Hydrocyclone, Chutes, Stackers & Reclaimers , Skirt Liners, Deflectors, Impact Plates, Bins, Hoppers, Pipes..

Product detail pictures:

Related Product Guide:

Desulphurization Vortex Nozzle – Perfect For Mass Transfer Roles

Acid scrubber

Manufacturing Companies for Silicon Carbide Spiral Nozzle - Wear-resistance-part-in-Mine – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.