Tegulae ceramicae industriales resistentes attritioni, tegumenta

![]()

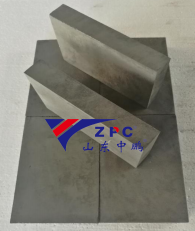

Silicium carburum reactione coniunctum (SiSiC vel RBSIC) est materia idealis resistentiae attritionis, quae est...

praecipue aptum ad abrasiva fortia, particulas crassas, classificationem, concentrationem, dehydrationem et

alia operationes. Late adhibetur in industria fodinarum, industria ferri, industria coralliorum tractandorum, industria chemica

industria, industria materiarum rudis faciendarum, obsignatio mechanica, tractatio superficiei sabulosa et reflector etc.

Gratias optimae duritiae et resistentiae abrasioni, partem ubi detrimentum requirit efficaciter protegere potest.

praesidium, ut vita utilis instrumentorum prolongetur.

Quomodo laminas, tegulas, et linteamina e carburo silicii altae qualitatis, quae detritioni resistentes sunt, agnoscere et invenire possumus?

Tegulae, tegumenta, tubi e carburo silicii resistentibus attritioni in industria fodinarum magis magisque adhibentur.

Haec ad referentiam tuam sunt:

1. Formula et processus:

Multae formulae SiC in foro exstant. Utimur authenticis formulis Germanicis. In probationibus laboratorio peractis, iactura Erosionis ㎝³ producti nostri ad 0.85 ± 0.01 pervenire potest;

2. Duritia:

Tegulae SiC in ZPC producuntur: nova duritia Mohs: 14.55 ± 4.5 (MOR, psi)

3. Densitas:

Densitas tegularum ZPC SiC est circiter 3.03 + 0.05.

4. Magnitudines et Superficies:

Tegulae SiC in ZPC sine fissuris et poris fabricatae, cum superficiebus planis et marginibus angulisque integris.

5. Materiae internae:

Tegumenta/tegulae e carburo silicii resistentes attritioni materias internas et externas tenues et uniformes habent.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Specificationes:

| Res | Unitas | Data |

| Temperatura applicationis | Celsius | 1380℃ |

| Densitas | G/cm³ | >3.02 |

| Porositas aperta | % | <0.1 |

| Robur flexionis -A | MPA | 250 (20℃) |

| Robur flexionis -B | MPa | 280 (1200℃) |

| Modulus elasticitatis-A | GPa | 330 (20℃) |

| Modulus elasticitatis -B | GPa | 300 (1200℃) |

| Conductivitas thermalis | W/mk | 45 (1200℃) |

| Coefficiens expansionis thermalis | K-1 ×10-6 | 4.5 |

| Rigiditas | / | XIII |

| Alcalinum acidis resistens | / | praeclarus |

■Formae et magnitudines praesto:

Crassitudo: a 6mm usque ad 25mm

Forma Regularis: Lamina SISIC, Tubus SISIC, Nexus Tres SiSiC, Cubitus SISIC, Cyclon Conicus SISIC.

Nota: Aliae magnitudines et formae petentibus praesto sunt.

■Involucrum:

In arca chartacea, in palleta lignea fumigata cum pondere netto 20-24MT/20′FCL inclusa.

■Commoda praecipua:

1. Excellens resistentia attritionis, resistentia impacti et resistentia corrosionis;

2. Planities excellens et resistentia temperaturae excellens usque ad 1350℃

3. Facilis installatio;

4. Diuturnior vita utilis (circiter septies maior quam ceramicae aluminae et decies maior quam...)

polyurethanum

Exemplar abrasionis impactus angularis Abrasio labens angularis humilis

Cum fluxus materiae abrasivae superficiem detritam angulo parvo attingit vel ei parallele transit, genus detritionis quod in frictione fit abrasio labens appellatur.

Ceramicae carburi silicii provectae tegulas et tegumenta ceramica resistentiam attritionis et corrosionis praebent. Hae res comprobatae sunt in apparatu translationis, processus, et repositionis. Nostrae tegulae crassitudine ab 8 ad 45 mm produci possunt. Interest tibi curare ut res requisitas adipiscaris. SiSiC: Durities Moh 9.5 est (nova durities Moh 13 est), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasioni et anti-oxidationis. Quattuor ad quintuplo validior est quam carburus silicii nitrido-iunctus. Vita utilis quintuplo ad septies longior est quam materiae aluminae. Morbilitas operandi RBSiC quintuplo ad septies maior est quam SNBSC, ita ad formas complexiores adhiberi potest. Tegumentum ceramicum resistens attritionis conductivum est ad meliorem efficaciam productionis, efficientiam operandi, reductionem sumptuum sustentationis, et augmentum lucri.

Ceramicae accuratae scientiam materiarum, peritiam applicatam, et artes ingeniarias habent. Hoc efficaciter curare potest ut optimae solutiones clientibus nostris offerantur. Tegulae et tegumenta ceramica carburi silicii saepe in applicationibus ut cyclones, tubi, canales, infundibula, fistulae, taeniae transportatoriae, et systemata productionis adhibentur. In hoc systemate, res mobiles in superficie labentes sunt. Cum res in materia labitur, partes lente deteritur donec nihil remaneat. In ambitu magnae attritionis, hoc frequenter fieri et multa problemata sumptuosa causare potest. Structura principalis retinetur materia durissima, ut ceramica carburi silicii et ceramica aluminae, ut tegumentum sacrificiale. Simul, ceramica carburi silicii diutius attritum tolerare potest antequam substitui necesse sit, vita utilis ceramicae carburi silicii quinquies ad septies longior est quam materia aluminae.

Proprietates Tegularum Ceramicarum et Linimentorum e Carbido Silicio Resistentium Attri:

Resistentia chemicis

Electrice insulans

Erosioni mechanicae et abrasioni resistens

Substituibilis

Commoda Tegularum et Tegumentorum Ceramicorum Resistentium Attritioni:

Adhiberi potest ubi tolerantiae strictae vel tenues membranae requiruntur.

Adhibi potest ad areas iam existentes, quae detrimento obnoxiae sunt, reficiendas.

Cum multis modis adhaerendi, ut ferrugine et glutino, adhiberi potest.

Ad usus specificos ad usum specificum designatum

Summa resistentia corrosionis

Solutio levis ad detritionem minuendam

Partes mobiles quae magno detrimento obnoxiae sunt protegit.

Significanter diuturnitas et efficacitas solutiones ad detritionem minuendam praestat.

Temperatura usus maxima altissima usque ad 1380°C

1. Officina ferri et chalybis: 1, stratum tympani machinae sinterizationis 2, tympanum gummi ceramico involutum 3, impeller ventilabri 4, alimentator discoidali, alveus materiae siccae 5, infundibulum coci, receptaculum convertoris, receptaculum coci, collector pulveris cyclonici.

2. Centralis electrica: 1. Exitus molae globulorum, voluta molae, exitus molae mediae celeritatis, cubitus tubi pulveris, collector pulveris cyclonici, silo, infusor 2. Infusor carbonum, separator pulveris crassi et subtilis, exitus molae carbonum, infusor carbonum transportandi 3. Infusor carbonum prensoris pontis, infusor carbonum medius fossoris carbonum, exitus molae globulorum, introitus et exitus separatoris pulveris crassi et subtilis, voluta extractoris pulveris. 4. Varia genera caminum currentis continui, turbidi densi et diluti, altae temperaturae, resistentium attritioni, pro caldariis carbonibus accensis; tubi et cubiti compositi ceramici valde resistentes attritioni, caminum ceramicum, ventilatores ceramici, impellers ceramici, valvae ceramicae, etc.; variae partes resistentes attritioni, ut globi molendi, manicae cylindri, disci molendi, tegulae discorum, anuli molendi, globi fistularum et aliae partes resistentes attritioni pro molis carbonum mediae celeritatis; tubi, amortiguator resistentis attritioni et ventilatores variarum specificationum pro systematibus pulverisandi et cineris removendi. Globi: Omnia genera molendina habent (vel non) tegulas internas, laminas internas, tubos spirales, anulos dentatos, globos chalybis mixti cum chromio humili, etc.; rotam percutientem, laminam percutientem, hamum custodialem, armaturam, separatorem, tubum fumi fornacis altae temperaturae, etc. pro mola carbonis ventilata; accessiones necessariae pro variis generibus machinarum contundentiae.

3. Mola chartae: 1. Tubus carbonis pulverisati

Praecipua producta et officia: 1. Tubi ceramici industriales detritioni resistentes: omne genus ceramici detritioni et altae temperaturae resistentis, carbone pulverato, reliquiis, scoria, luto obducti, fistulae translationis luti, cubiti, cubiti, combustores carbonis pulverati, exitus molendini carbonarii, separatores cyclonici pulveris crassi et subtilis, canales, infundibula, receptacula repositionis, dolia praeparationis mineralis, separatores magnetici fodinae; 2. Ventilator ceramicus detritioni resistentes: omne genus turbinis et volutae ventilatoris altae temperaturae resistentis, detritioni, et corrosioni resistentes, inter quae ventilator centrifugus, ventilator fluxus axialis, lamina statica, turbinis ventilatoris laminae mobilis adaptabilis, ventilator suctionis, extractoris pulveris, ventilatoris sinterizationis, ventilatoris separationis pulveris, ventilatoris remotionis pulveris, ventilatoris capitis et caudae furni, etc.; 3. Antlia et valvula ceramica detritioni resistentes: obducta ceramica, turbinis antliae, testa, deflector, cubitus tubi, valvula pneumatica remotionis cineris et transmissionis gasis et accessiones variarum sorbitionum, scoriarum, mortarii, reliquiarum et aliorum systematum translationis. 4. Tegumenta ceramica resistentia attritionis: omnia genera tegumentorum ceramicorum et mastici resistentia attritioni et altae temperaturae in volutis ventilabri, tubis cubitalibus, exitu molendini, tubis separationis crassis et subtilibus, canaliculo, infundibulo et valvula adhibentur. 5. Apparatus separationis magneticae resistentia attritioni: partes meatus fluxus variarum instrumentorum tractationis mineralium siccorum et humidorum, inter quas tympanum separationis magneticae, sulcus inferior, canaliculus, tubulus, variae antliae luti, voluta antliae sorbentis, impeller, et tubulus translationis. 6. Technologia aspersionis superficialis: utens recentissimo fonte potentiae arcus pulsatilis inverter internationalis et sclopeto aspersionis arcus celeris, variae materiae metallicae resistentes attritioni et anticorrosioni in superficiem substrati metallici asperguntur ut stratum protectivum resistente attritioni et anticorrosioni forment. Hoc efficax praesidium praebere potest contra omne genus corrosionis attritioni mediae fortitudinis.

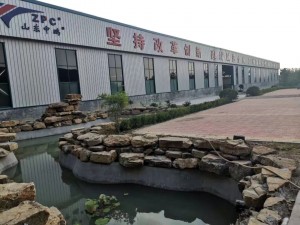

Ceramica Shandong Zhongpeng ZPC est societas in productione ceramicarum industrialium specializata, praecipue in investigatione et evolutione (R&D) et productione ceramicarum carburi silicii occupata. Producta ceramica secundum delineationes vestras conficere possumus, in productione virgarum ceramicarum magnae magnitudinis et altae praecisionis, tuborum ceramicorum, anulorum ceramicorum, laminarum ceramicarum, flangium ceramicarum, fistularum ceramicarum, et partium magnae magnitudinis et detritioni resistentium ad usum personalizatarum specializantes.

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.