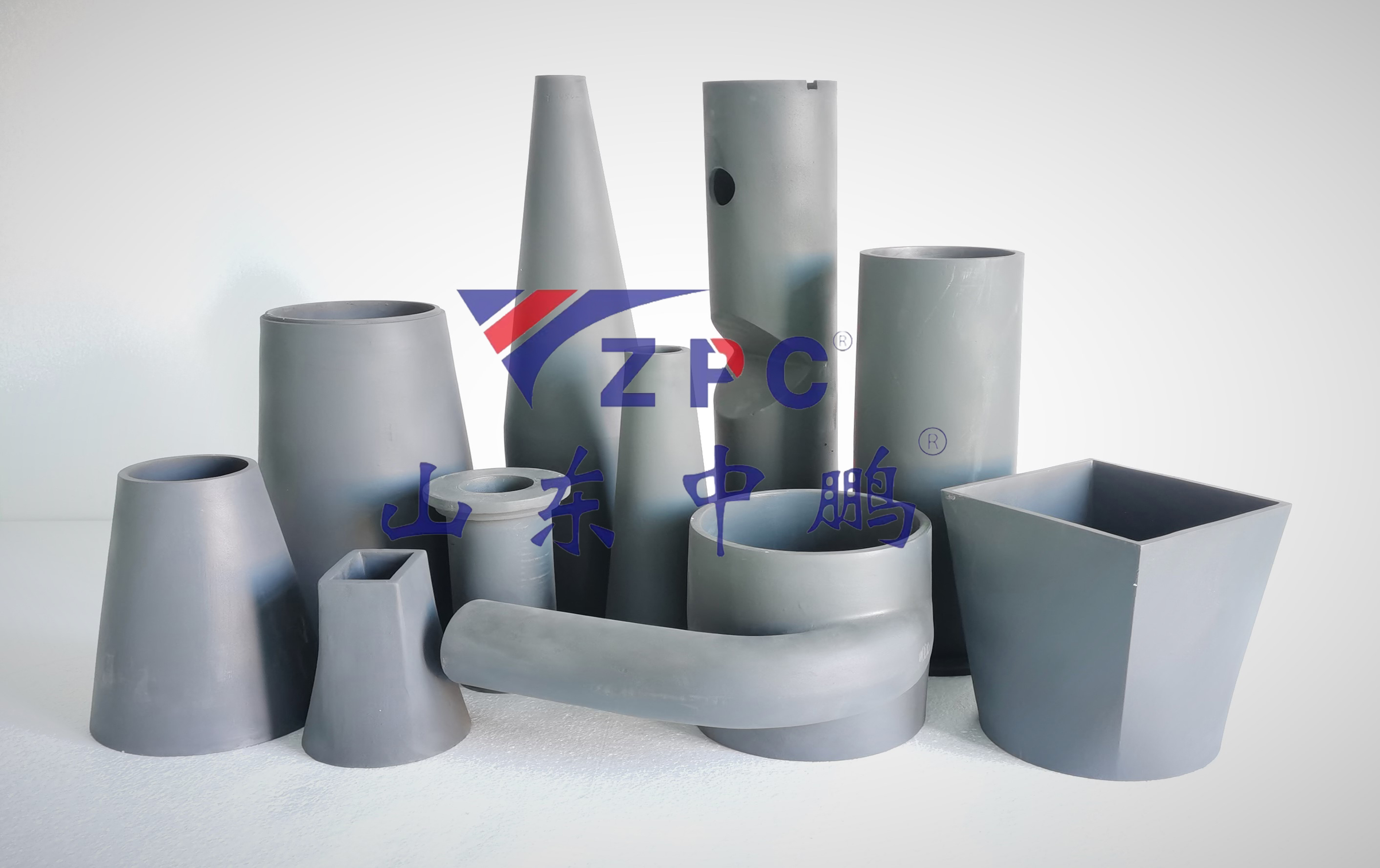

Tegumenta ceramica carburi silicii

Tegumentum carburi silicii detritioni resistens

Proprietates Designandi Tegumentorum Silicon Carbide (SiC) Resistentium Attritioni:

(1) Designatio Viae Fluxus Efficax

Forma lenis et aerodynamica ab introitu ad exitum resistentiam fluxus minuit, ita ut integmina SiC ad varias applicationes industriales aptabilia sint.

(2) Atomizatio Provecta

Mechanismus Liquores in guttas minutas atomizantur per collisiones tangentiales cum superficiebus helicalibus tegumenti SiC progressive angustantibus, distributionem uniformitatem pulveris efficientes.

(3) Structura Compacta, Sine Obstructionibus

Canalis fluxus rectus et sine nucleo obstructiones internas eliminat, fluxum fluidi intra dimensiones tuborum angustas amplificans, obstructiones simul prohibens.

(4) Modi Duplices Spray ad Efficientiam Auctam

Exempla spargendi et coni solidi et coni cavi sustinet, angulos opertionis latos et vim anti-obstructionis ad operationes summae efficientiae offerens.

Commoda principalia comparata cum aliis materiis:

(1) Resistentia ad attritionem incomparabilis

Duritia: Tegumenta SiC duritiem Mohs 9.5 assequuntur (contra 8.0 pro ceramicis aluminae, 6.0 pro chalybe alto chromio), quod eis permittit tolerare abrasionem extremam in pulveribus fodinarum, cinere carbonis, et pulveribus metallicis.

Longaevitas: Vita utilis quinquies ad decies plus quam materiae traditionales (e.g., tegumenta gummi vel polyurethane) in applicationibus magni impetus sicut molendina globulorum vel antliae pulveris liquidi excedit.

(2) Corrosio et Inertia Chemica

Resistentia Acido/Alcali: Resistit acido sulfurico concentrato (98%), natrii hydroxido (50%), et salibus liquefactis (e.g. NaCl-KCl ad 800°C), dum metalla celeriter corrodunt et polymeri degraduntur.

Nulla Contaminatio: Superficies non-reactiva puritatem in productione semiconductorum vel accumulatorum lithii praestat, dissimilis tegumentis ferreis quae ad lixiviationem ionicam prona sunt.

(3) Stabilitas Temperaturae Extremae

Robur Thermale: Continuo operatur ad 1600°C (contra limitem aluminae 1200°C) cum minima expansione thermali (CTE: 4.0×10⁻⁶/℃), prohibens fissuras in furnis vel caminis fusionis.

Resistentia Ictui Thermali: Integritatem structuralem sub rapidis fluctuationibus temperaturae (e.g., refrigeratione ab 1000°C ad temperaturam ambientem) conservat, dissimilis ceramicis fragilibus.

(4) Efficientia Energiae et Designatio Levis

Frictio Parva: Superficies SiC polita (Ra <0.1 μm) resistentiam fluidorum 30-50% minuit comparata cum tegumentis chalybeis asperis, sumptus energiae pumpandi minuens.

Pondus Reductum: Densitas 3.1 g/cm³ (contra 7.8 g/cm³ chalybis) institutionem faciliorem reddit et apparatum leve in industrie aëronautica vel unitatibus mobilibus processus sustinet.

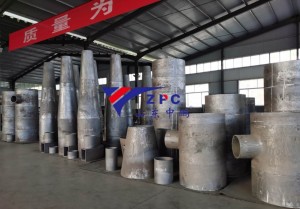

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.