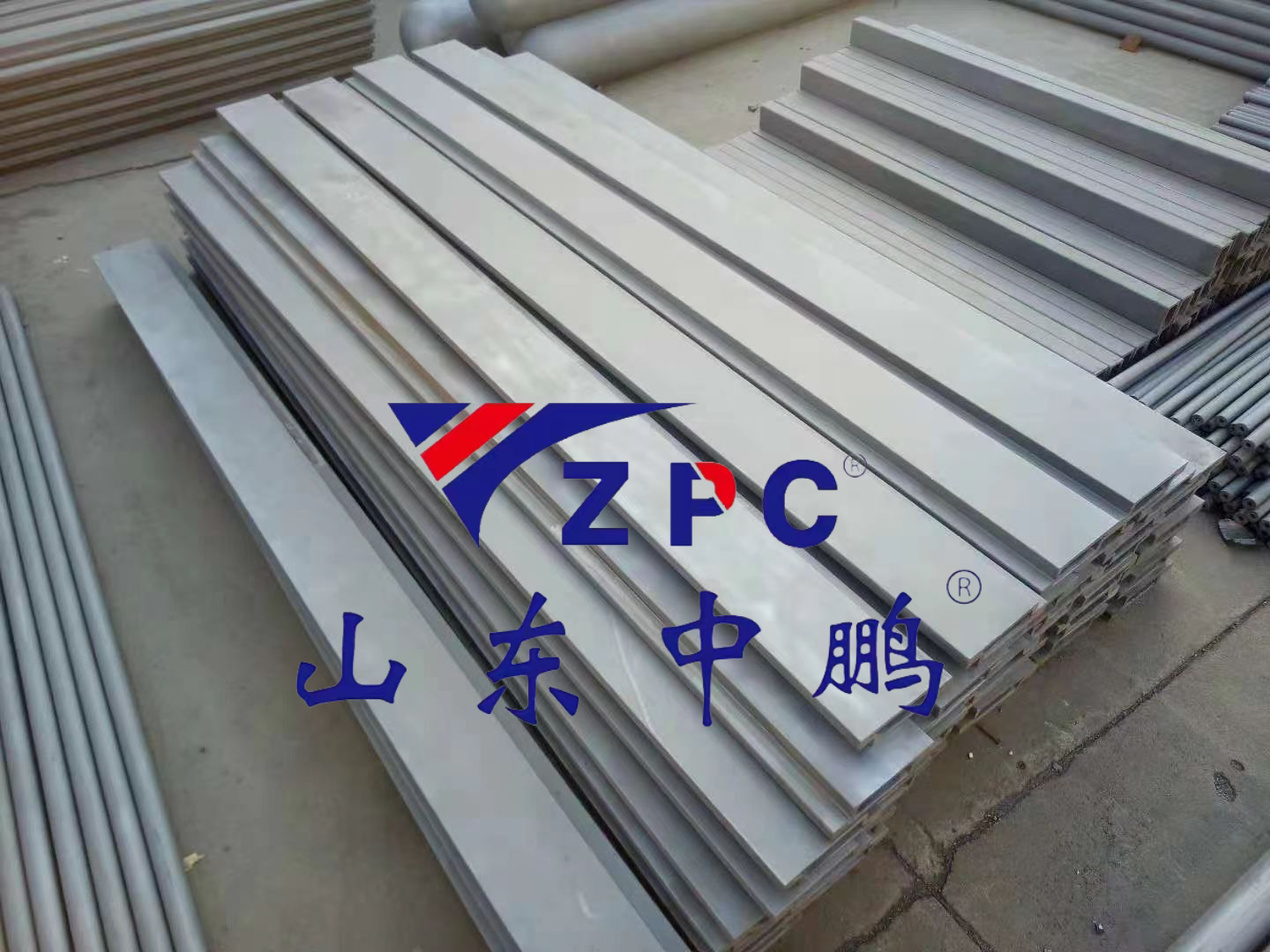

Trabes carburi silicii

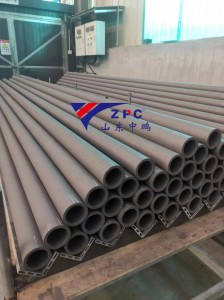

Cylindri ceramici e carburo silicii reactione-sinterizato (R-SiC)In hodiernis systematibus processus thermalis quasi partes criticae emerserunt, praecipue excellentes in fabricatione accumulatorum lithii, productione ceramicarum provectarum, et sinteratione accurata materiarum magneticarum. Hi cylindri specializati normas functionis in furnis industrialibus altae temperaturae denuo definiunt, provocationibus clavis in stabilitate thermali et durabilitate mechanica tractandis.

Incomparabilis Efficacia Thermica

Ad operandum continuo inter 1450-1600°C designati – multo altius quam cylindri aluminae traditionales – cylindri R-SiC praecisionem dimensionalem etiam sub cyclis thermalibus extremis servant. Microstructura singularis earum permittit:

• Celeris uniformitas transmissionis caloris (±5°C per longitudinem cylindri)

• Plus quam centum cyclis impetus thermalis sustinens (1400°C ↔ temperatura ambiente)

• Deformatio repentis nulla ad temperaturas altas diuturnas

Applicationes Criticae Redefinitae

1. Productio Accumulatorum Lithii

- Praecisa ordinatio ad materiam electrodi sinterizandam

- Tractatio cathodorum NMC/LFP sine contaminatione

- Operatio stabilis in atmosphaeris reducentibus

2. Processus Ceramicae Provectus

- Sustentatio sine distorsione pro tegulis magni formae (usque ad 1.5×3m)

- Imperium celeritatis constans in lineis vitrificationis instrumentorum sanitariorum

- Superficies non vestigia relinquens (Ra <0.8μm)

3. Fabricatio Materiae Magneticae

- Rotatio sine vibratione ad sinterizationem ferritorum orientatorum

- Inertia chemica in ambitu hydrogenio divite

Commoda Operationalia

Capacitas Oneris: Pondus per unitatem longitudinis 3-5× maius sustinet quam cylindri ex mixtura metallica.

Resistentia Deformationis: Rectitudinem <0.05mm/m post 10,000 horas operationis conservat.

Efficacia Energiae: Consumptionem energiae fornacis 18-22% reductam per distributionem caloris optimizatam

Compatibilitas Inter Industrias: Adaptabilis ad furnos mobiles, focos volubiles multistratos, et furnos cuniculares hybridos

Sustinebilitas Oeconomica

Dum investmentum initiale 30-40% maius quam cylindri usitati requirunt, solutiones R-SiC demonstrant:

- Intervalla servitii 70% longiora (anni 5-7 contra annos 2-3)

- 90% redivivibilitas per processus recuperationis thermalis

- Sumptus conservationis 60% minores ex superficiebus abrasioni resistentibus

Designatio ad Futurum Parata

Cylindri moderni R-SiC nunc includunt:

- Sulci vestigationis laser-incisi pro lineis productionis automatis

- Porositas adaptabilis pro permeabilitate atmosphaerica specifica

- Sensoria thermica integrata ad operationes furnorum callidiores

Hae progressiones technologicae cylindros carburi silicii per reactionem sinteratos ut partes indispensabiles in systematibus calefactionis industrialis novae generationis collocant, fabricatoribus permittens ut temperaturae moderationem strictiorem, constantiam producti maiorem, et fluxus productionis sustentabiles per multos sectores technologiae altae consequantur.

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.