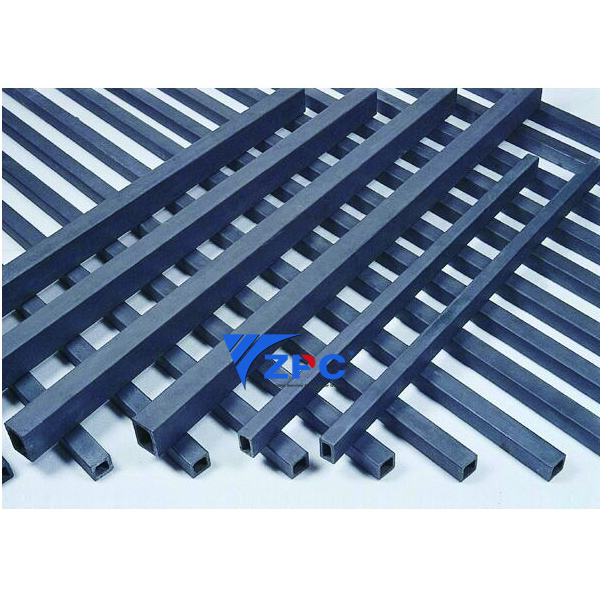

Trabes SiC

Cylindri et Trabes Silicii Carbidi Reactione Ligati, Altae Roboris, Altae Rectitudinis, Sisici/Rbsici

Cylindrus ceramicae carburi silicii per reactionem sinterizationis imprimis adhibetur in industria accumulatorum lithii, porcellana quotidiana, porcellana sanitaria, ceramica aedificatoria et materiis magneticis, ut in fornacibus cylindricis, ad altam temperaturam comburendum cum fornace ideali, cum longa vita utili. Habet firmitatem altae temperaturae, resistentiam ictui thermali, resistentiam reptationis altae temperaturae, resistentiam validam, bonam resistentiam attritionis. Cylindri cum capacitate altae temperaturae portantis, amplum usum diuturnum sine deformatione flexionis, praecipue apti pro fornacibus cunicularibus, fornacibus vectoriis, in fornacibus cylindricis duorum stratorum, et aliis structuris onerariis portantibus fornacum industrialium.

Sodalitates ad ceramicas quotidianas, porcelanam sanitariam, ceramicam aedificatoriam, materiam magneticam et zonam coquendi altae temperaturae fornacis cylindricis pertinent.

| Specificatio Producti Carbidi Silicii: | ||||

| Res | Unitas | SSIC | RBSIC SISIC | R-SIC |

| Puritas | (%) | ≥ 99 | ≥90% | ≥ 99 |

| Temperatura applicationis | °C | MDCC | 1380 | 1650 |

| Densitas | g/CM² | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Porositas aperta | % | ≤0.1 | ≤0.1 | |

| Duritia | ≥92 HRA | 2400 kg/mm² | 1800-2000 kg/mm² | |

| Robur flexionis | MPa | 400-580 | 250 (20°C) | ≥300 |

| 281 (1200°C) | ||||

| Robur tensile | MPA | ≥200 | ≥190 | |

| modulus elasticitatis | GPa | quadringenti | 332 (20°C) | 80-100 (20°C) |

| 300 (1200°C) | 90-110 (1200°C) | |||

| Conductivitas Thermalis | W/mk | 100-120 | 45 (1200°C) | 36 |

| Coefficiens expansionis thermalis | K1X 106 | 4.2 | 4.5 | 4.6 |

| Rigiditas | GPA | >25 | 13 | |

| Resistentia acidis et Ikali | Excellens | Excellens | Excellens | |

| Specificatio Producti SiC: | ||||

| Res | Unitas | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Porositas Apparens | (%) | ≤10 | ≤13 | ≤16 |

| Densitas | g/CM² | ≥2.66 | ≥2.63 | ≥2.6 |

| Temperatura applicationis | °C | ≥1680 | ≥1620 | ≥1550 |

| Coefficiens expansionis thermalis | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Vis Flexionis | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.