1. Resistentia corrosionis

Fistulae FGDIn ambitu valde corrosivo, ubi oxida sulphuris, chlorida, aliaque chemica aggressiva continentur, operari possunt. Ceramica carburi silicii (SiC) resistentiam corrosionis exceptionalem demonstrat, cum minore quam 0.1% amissione massae in solutionibus pH 1-14 (secundum probationem ASTM C863). Comparata cum chalybe inoxidabili (PREN 18-25) et mixturis niccoli (PREN 30-40), SiC integritatem structuralem sine foveolis aut fissuris corrosionis sub tensione conservat, etiam in acidis concentratis ad temperaturas elevatas.

2. Stabilitas Altae Temperaturae

Temperaturae operationis in systematibus desulfurationis fumorum humidorum typice variant inter 60 et 80°C, cum apicibus excedentibus 120°C. Ceramica SiC 85% suae firmitatis temperaturae ambientis ad 1400°C retinet, ceramicas aluminae (50% firmitatis amittens ad 1000°C) et chalybes calori resistentes superans. Eius conductivitas thermalis (120 W/m·K) dissipationem caloris efficientem permittit, accumulationem tensionis thermalis prohibens.

3. Resistentia ad attritionem

Cum duritia Vickers 28 GPa et tenacitate fracturae 4.6 MPa·m¹/², SiC resistentiam erosionis superiorem contra particulas cineris volantis (Mohs 5-7) exhibet. Experimenta in agro ostendunt fistulas SiC detritionem <5% post 20 000 horas servitii retinere, comparata cum detritione 30-40% in fistulis aluminae et completa defectu metallorum polymero obductorum intra 8 000 horas.

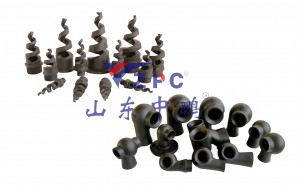

4. Proprietates Fluxus

Superficies SiC reactione iuncti (angulus contactus >100°) non-humectans dispersionem pulveris liquidae accuratam cum valoribus CV <5% permittit. Superficies eius ultra-laevis (Ra 0.2-0.4μm) pressionis casum 15-20% comparata cum injectionibus metallicis minuit, dum coefficientes emissionis stabiles (±1%) per operationem diuturnam servant.

5. Simplicitas Sustentationis

Inertia chemica SiC modos purgationis aggressivos permittit, inter quos:

- Iactus aquae altae pressionis (usque ad 250 bar)

- Purgatio ultrasonica solutionibus alcalinis

- Sterilisatione vaporaria ad 150°C

Sine periculo degradationis superficiei, quod in injectionibus metallicis polymero-inductis vel obductis commune est.

6. Oeconomia Cycli Vitae

Cum sumptus initiales pro fistulis SiC bis vel ter maiores sint quam pro chalybe inoxidabili 316L communi, vita utilis octo ad decem annorum (contra duos vel tres annos pro metallis) frequentiam substitutionis septuaginta% minuit. Sumptus totales possessionis ostendunt quadraginta ad sexaginta centesimas conservationes per decem annos, nullo tempore inactivo pro reparationibus in situ.

7. Compatibilitas Ambientalis

SiC incomparabilem efficaciam in condicionibus extremis demonstrat:

- Resistentia nebulae salis: 0% mutatio massae post 5000 horas probationis ASTM B117

- Operatio puncti roris acidi: Vaporibus H2SO4 160°C resistit

- Resistentia impetus thermalis: Superat cyclos extinctionis 1000°C → 25°C

8. Proprietates contra incrustationem

Structura atomica covalentis SiC superficiem non reactivam creat, cum ratibus squamositatis 80% minoribus quam in alternativis metallorum. Studia crystallographica ostendunt deposita calcitae et gypsi nexus debiliores (adhaesio <1 MPa) in SiC formare, contra >5 MPa in metallis, quod faciliorem remotionem mechanicam permittit.

Conclusio Technica

Ceramica carburi silicii per aestimationem perfunctionis comprehensivam optima electio materiae pro fistulis FGD emergit:

- Vita utilis decies longior quam alternativae metallicae

- 92% reductio in curatione improvisa

- Augmentum 35% in efficacia remotionis SO2 per constantes formas spargendi

- Plena obsequium cum EPA 40 CFR Part 63 emissionum normis

Progredientibus artibus fabricationis, ut sinterizatione phasis liquidae et obductione CVD, fistulae SiC novae generationis superficies submicronicas et geometrias complexas antea in ceramicis inattingibiles consequuntur. Haec evolutio technologica silicium carburum ut materiam electam pro systematibus purgationis fumorum novae generationis ponit.

Tempus publicationis: Martii XX, MMXXXV