Discrepantiae inter ceramicas aluminae et ceramicas carburi silicii

Tegulae Carburis Silicii resistentes attritioni et tegulae Aluminae—Hae sunt boni socii qui inter se in industria resistenti attritioni cooperari possunt.

Tegulae ceramicae aluminae late in industriis detritionis in metallis fodinis vel corrosionis chemicae adhibentur. Attamen, in quibusdam regionibus ubi corrosio et detritio gravissimae sunt, efficacia ceramicae aluminae valde minuitur. Valde commendamus ut laminas ceramicas carburi silicii vel tegumenta ceramica carburi silicii adhibeas. Ceramica technica SiC: duritia Moh 9 est (nova duritia Moh 13 est), praeclara resistentia erosioni et corrosioni, excellenti resistentia abrasioni et anti-oxidationis praebet. Vita utilis producti SiC quinquies ad decies longior est quam materiae aluminae 92%. Vita utilis producti RBSiC quinquies ad septies maior est quam SNBSC, ita ut ad formas complexiores et tegumenta maiora adhiberi possit.

ZPC crustulas ceramicas e carburo silicii magis oeconomicas et aptas in magna copia producit, et inter duces in productione crustularum ceramicarum in Sinis sumus. Vita utilis fistulae e carburo silicii septies ad decies maior est quam fistulae e carburo aluminae. Ceramicae e carburo silicii sunt ceramicae industriales maximae duritiae quae hodie maturescere et adhiberi possunt. Ceramicae e carburo silicii et ceramicae e zirconio paulatim in multis condicionibus laboris substitutae sunt. Ceramicae e carburo silicii plasticitatem fortem habent et multa genera partium formae specialis et magnitudinis magnae producere possunt.

Discrepantiae inter ceramicas aluminae et ceramicas carburi silicii:

Shandong Zhongpeng Special Ceramics Co., Ltd est productio professionalis ceramicarum Magnae Magnitudinis Reaction Bonded Silicon Carbide (RBSiC vel SiSiC). Producta ZPC RBSiC (SiSiC) stabilem functionem et qualitatem excellentem habent. Societas nostra certificationem systematis qualitatis ISO9001 superavit. RBSC (SiSiC) magnam habet fortitudinem, magnam duritiem, altam resistentiam temperaturae, resistentiam attritionis, resistentiam corrosionis, resistentiam oxidationis, resistentiam ictui thermali, bonam resistentiam ictui thermali, bonam conductivitatem thermalem, altam efficientiam thermalem, etc. Nostra producta late adhibentur in industria fodinarum, centralibus electricis, apparatu remotionis pulveris desulfurizationis, fornace ceramica altae temperaturae, fornace extinctionis chalybis, cyclone classificationis materiae fodinarum, etc., involucro coni carburi silicii, cubito carburi silicii, involucro cyclonico carburi silicii, tubo carburi silicii, epistolio carburi silicii, involucro vorticis carburi silicii, introitu carburi silicii, involucro hydrocycloni carburi silicii, involucro hydrocycloni magnae magnitudinis, involucro hydrocycloni 660, involucro hydrocycloni 1000. Categoriae productorum (SiSiC) includunt rostrum pulverizationis desulfurizationis, rostri combustoris RBSiC (SiSiC), tubum radiationis RBSic (SiSiC), permutatorem caloris RBSiC (SiSiC), trabes RBSiC (SiSiC), cylindros RBSiC (SiSiC), involucrum RBSiC (SiSiC) etc.

Tegumentum carburi silicii sinterizatum ZPC Reaction late in fodinis, contundendo mineralia, cribrando, et transportando materiam fluidorum magnae detritionis et corrosionis adhibetur. Corticem chalybis carburi silicii, ob bonam resistentiam abrasionis et corrosionis, aptum est ad transportandum pulverem et limum, late in fodinis adhibitum.

Solutio ZPC parata ad separatores hydrocyclonum limosorum aliosque apparatus ad mineralia tractanda praebet, capsulata completa et ab uno fonte praebita, intra paucas hebdomades. Ubi opus est, formulae nostrae propriae, e carburo silicii fundatae, in formas complexas fundi et deinde in polyurethano intra domum includi possunt, facilitatem institutionis, mitigationem fissurarum et auctam cautionem detritionis praebentes, dum solutionem completam ab uno venditore praebent. Processus specialis et sumptum et tempus productionis clientibus minuit, dum productum cum maiori firmitate et fidelitate praebet.

Omnes materiae propriae e carburo silicii fundatae in formas valde complexas fundi possunt, tolerantias arctas et repetibiles exhibentes, quae facilitatem institutionis repetitam praestant. Exspecta productum abrasioni resistentiorem quam chalybes fusi, gummi et urethani soli, qui tertia parte ponderis eorum similium chalybis ponderabunt.

Tegumentum e carburo silicii (RBSC) est genus novi materiae attritionis resistens. Materia tegumenti praedita est magna duritie, resistentia abrasioni et impacti, resistentia temperaturae altae, resistentia acidis et alcali, resistentia corrosionis, aliisque notis, et vita utilis sexies maior quam tegumenti aluminae. Praecipue aptum est particulis crassis et valde abrasivis in classificatione, concentratione, dehydratione, aliisque operationibus, et in multis fodinis feliciter adhibitum est.

Involucrum et Transportatio

Involucrum: arca lignea et palletta exportationis normae

Vectura: per navem secundum quantitatem ordinis tui

Servitium:

1. Exemplum ad probationem ante ordinem praebe.

2. Productionem tempore constitue

3. Qualitatem et tempus productionis moderare

4. Producta perfecta et imagines involucrorum praebe.

5. Traditio tempore suo et documenta originalia praebe.

6. Servitium post venditionem

7. Pretium continuum competitivum

Semper credimus solam esse cautionem, producta altae qualitatis et honestum officium, ad diuturnam cooperationem cum clientibus nostris conservandam!

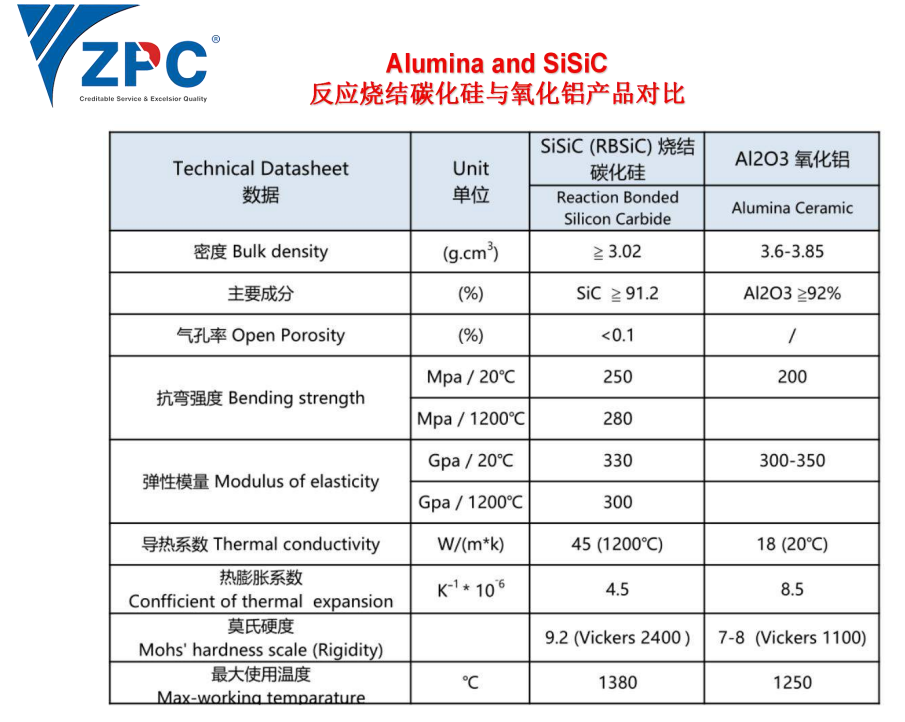

| RES | /UINT | /DATA |

| Temperatura Maxima Applicationis | Celsius | 1380℃ |

| Densitas | g/cm³ | >3.02 g/cm³ |

| Porositas Aperta | % | <0.1 |

| Vis Flexionis | MPA | 250Mpa (20℃) |

| MPA | 280 MPa (1200℃) | |

| Modulus Elasticitatis | GPa | 330GPa (20℃) |

| GPA | 300 GPa (1200℃) | |

| Conductivitas Thermalis | W/mk | 45 (1200℃) |

| Coefficiens Expansionis Thermalis | K-1*10-6 | 4.5 |

| Duritia Moh | 9.15 | |

| Duritia Vickers HV | GPA | 20 |

| Acido Alcalino Resistens | Excellens |

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.