SiC Crucibles na Saggers emeputa / ụlọ ọrụ - SiC Sagger maka ntụ ntụ Sintering

SiC Sagger maka Powder Sintering

RBSIC/SISIC crucible bụ nnukwu efere dị omimi nke ite seramiiki. N'ihi arụmọrụ ya dị mma karịa iko iko na nguzogide okpomọkụ, a na-eji ya eme ihe nke ọma mgbe ọkụ na-ekpo ọkụ.

Sagger bụ nke refractory apịtị nke dị iche iche nkọwa nke ngwa agha, butere na elu okpomọkụ. Ọ bụ otu n'ime ngwá ụlọ dị mkpa maka ọkụ ọkụ. A ga-ebu ụzọ tinye ụdị poselin niile n'ime saggers wee banye n'ime ọkụ maka ịsa nri.

Nkọwapụta:

| Index | RSiC | NSiC | RBSiC | SiC |

| Njupụta nnukwu (g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Ọgba aghara(%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Ike na-ehulata (MPa) | 80-100 (20 ℃) | 160-180 (20 ℃) | 250 (20 ℃) | 500 (20 ℃) |

| Ike na-ehulata (MPa) | 90-110 (1200 ℃) | 170-180 (1200 ℃) | 280 (1200 ℃) | 550 (1200 ℃) |

| Ike na-ehulata (MPa) | 90-120 (1350 ℃) | 170-190 (1350 ℃) | - | - |

| Modul nke elasticity (GPa) | 300 (20 ℃) | 580 (20 ℃) | 330 (20 ℃) | 200 |

| Modul nke elasticity (GPa) | - | - | 300 (1200 ℃) | - |

| Nrụpụta ọkụ (wm-1.k-1) | 36.6 (1200 ℃) | 19.6 (1200 ℃) | 45 (1200 ℃) | 13.5-14.5 (1000 ℃) |

| Ọnụọgụ nke mgbasawanye thermal (K-1×10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Isi ike | - | - | 13 | - |

| Oke okpomọkụ na-arụ ọrụ (℃) | 1620 (oxide) | 1450 | 1380 | 1300 |

Ụlọ ọrụ:

Gbasara anyị:

Anyị bụ ụlọ ọrụ ọkachamara na mmepụta nke RBSIC/SISIC Silicon Infiltrated Silicon Carbide Products.

- Usoro mmepụta ọkachamara

- Ngwa ngwa ngwa dị elu ebubata

- Usoro njikwa mmepụta zuru oke

katalọgụ:

Uru:

- Ike dị elu na oke ike

- Akwa okpomọkụ na-eguzogide na magburu onwe thermal ujo iguzogide

- Magburu onwe ibu ike

- Iguzogide oke okpomọkụ na oyi.

- Akwa okpomọkụ na-akpụ akpụ iguzogide

- Nguzogide corrosion na nguzogide Oxidation

- Acid na alkali iguzogide

- Yiri nguzogide&ezi nke thermal conductivity

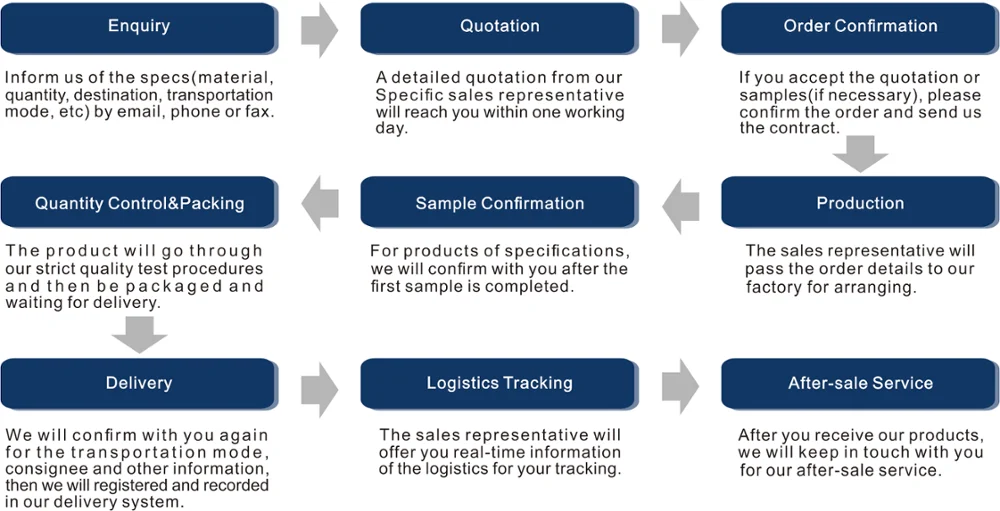

Usoro iwu:

Usoro mmepụta:

The silicon carbide ceramics crucibles na saggers nwere ike iji dị iche iche ntụ ntụ sintering, metal smelting, wdg na ubi nke metallurgy, chemical ụlọ ọrụ, iko na ihe ndị yiri ya. Shandong Zhongpeng na-agba mbọ na nyocha na mmepe, mmepụta na ahịa nke ngwaahịa silicon carbide dị elu, ngwaahịa ndị bụ isi bụ mmeghachi omume sintered silicon carbide seramiiki ibé, ihe mkpuchi rola, ọkụ nozzles, ikuku ikuku oyi, shei, enamel, enamel, thermocouple nchebe tube, okpomọkụ mgbanwe tube, radiant tube n'ime tubesul, tube nke ikuku na-enweghị ike ime, tube nke ikuku ikuku, tube nke ikuku ikuku, tube nke ikuku ikuku, ikuku ikuku. ọkụ tube, ájá na-agbawa nozulu, bushing, akara na dị iche iche elu okpomọkụ, eyi na corrosion na-eguzogide silicon carbide seramiiki ekara Piece, wdg, mmeghachi omume sintered silicon carbide seramiiki ngwaahịa na elu ike, elu ike ike, eyi iguzogide, elu okpomọkụ na-eguzogide, corrosion iguzogide, oxidation iguzogide, thermal ujo na-eguzogide na thermal conductivity, iguzogide na-ekpo ọkụ na okpomọkụ na ọtụtụ ebe, okpomọkụ na-eguzogide na-na-na-na-na-na-ekpo ọkụ na okpomọkụ na-na-na-na-na-na-na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na okpomọkụ. ike nuklia, kristal mmiri mmiri na ọla, kemịkalụ, igwe, ụgbọ ala, akwụkwọ, ọgwụ na mpaghara ndị ọzọ, a na-ebupụ ngwaahịa na United States, Germany, Japan, South Korea, United Arab Emirates, South Africa, Taiwan na ndị ọzọ karịa mba 40 na mpaghara.

mmeghachi omume bonded silicon carbide (SiSiC): Isi ike Moh bụ 9.5, nwere ezigbo nguzogide mbuze na corrosion, ezigbo abrasion-eguzogide na mgbochi oxidation. Ọ dị okpukpu 4 ruo 5 ike karịa silicon carbide nitride bonded. Ndụ ọrụ bụ oge 7 ruo 10 karịa ihe alumina. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya.

Nkwakọ ngwaahịa:

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.