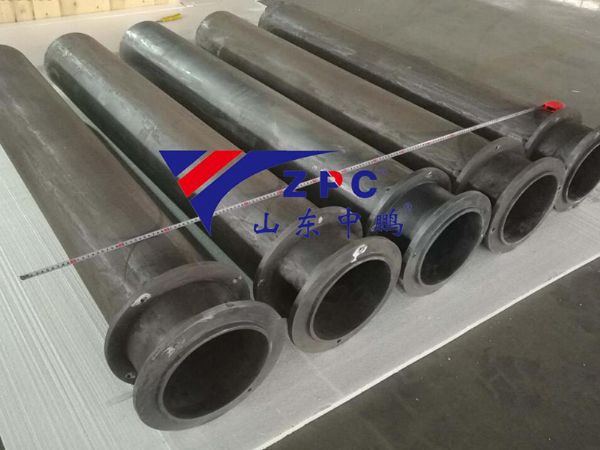

Silicon carbide tube nchebe

N'ime ụlọ ọrụ ebe oke ọnọdụ na-eyi iguzosi ike n'ezi ihe akụrụngwa egwu,tubes nchebe silicon carbide (SiC).pụta dị ka ihe ngwọta n'ala. N'adịghị ka ihe mkpuchi ihe, SiC tubes na-ejikọta sayensị ihe onwunwe dị elu na injinịa siri ike iji chekwaa ngwa na usoro dị oke egwu. Ọ nwere uru ndị a:

1. Nchedo enweghị atụ na ọnọdụ ọjọọ

Igwe nchekwa SiC na-arụ ọrụ dị ka ụzọ nchebe mbụ na gburugburu ebe ọdịda abụghị nhọrọ:

(1) Nchekwa okpomọkụ: Nagide okpomọkụ na-adịgide ruo 1600C, ihe mmetụta nchebe, thermocouples, ma ọ bụ nyocha sitere na ọla a wụrụ awụ, ọkụ na plasma.

(2) Ihe mgbochi kemịkalụ: guzogide corrosion sitere na acids (dịka sọlfọ, hydrochloric), alkalis, na gas na-arụ ọrụ dị ka chlorine ma ọ bụ sọlfọ oxides.

Mgbochi abrasion: Chebe megide ụmụ irighiri ihe na-emebi emebi n'ime akwa mmiri nwere mmiri, gasifiers coal, ma ọ bụ ọrụ Ngwuputa.

2. Nkenke na kwụsie ike maka nha dị oke egwu

N'ime usoro mmepụta ihe dị elu, izi ezi bụ ihe kacha mkpa. SiC tubes na-akwalite ntụkwasị obi site na:

(1) Mbelata nnyonye anya mgbaama: Njirimara ndị na-adịghị eduzi na-egbochi mmebi elektrọnik na sensọ eletrọnịkị.

(2) Thermal Stability: Na nso-efu thermal deformation na-eme ka nhazi na nha nha anya na-agbanwe agbanwe n'okpuru mgbanwe okpomọkụ ngwa ngwa.

(3) Iguzosi ike n'ezi ihe nke gas: Ọdịdị na-adịghị emebi emebi na-egbochi ntinye gas, dị mkpa maka sistemu agụụ ma ọ bụ ikuku a na-achịkwa.

3. Na-enyere Teknụzụ Ọgbọ na-esote SiC echebe ọkpọkọ imeghe ihe ọhụrụ na mpaghara na-apụta:

(1) Economy Hydrogen: Na-eje ozi dị ka sheaths na-adịgide adịgide maka ihe mmetụta na mmepụta hydrogen, nchekwa, na mkpụrụ ndụ mmanụ, na-eguzogide embrittlement na nnukwu nrụgide H₂.

(2) Mmepụta Semiconductor: Chebe ngwa anya na ihe mmetụta thermal na CVD (Chemical Vapor Deposition) reactors site na precursors corrosive dị ka silane ma ọ bụ amonia.

(3) Nchọgharị oghere: Ngwá ọrụ nchekwa n'ime igwe rọketi na nyocha mbara ala sitere na gradients dị oke ọkụ na radieshon mbara igwe.

4. Ọnụ-arụ ọrụ site na Ogologo ndụ

Ọ bụ ezie na tubes SiC nwere ọnụ ahịa dị elu dị elu, uru usoro ndụ ha na-akọwapụta uru:

(1) Mbelata Downtime: Ihe mgbakwunye ọla ma ọ bụ quartz dịpụrụ adịpụ site na 4–6x na ntọala abrasive ma ọ bụ acidic, na-ebelata mmezi enweghị atụmatụ.

(2) Ihe mkpuchi mkpuchi efu: N'adịghị ka ọla chọrọ mkpuchi nchebe, ihe ndị dị na SiC na-ewepụ ụgwọ ọgwụgwọ elu ugboro ugboro.

(3) Reusability: lanarị ọtụtụ usoro cycles na ngwa dị ka nkedo ígwè ma ọ bụ iko na-akpụ na-enweghị mmebi.

5. Nhazi maka mkpa pụrụ iche

Ọkụ nchekwa SiC na-adaba na ịma aka niche site na injinia ahaziri:

(1) Nhazi ngwakọ: jikọta na ọla ma ọ bụ seramiki maka mgbakọ na-arụ ọtụtụ ọrụ (dịka njikọ eriri, flanges).

(2) Mgbanwe ihu igwe: Ime ụlọ a na-egbu maramara maka ngwa anya ma ọ bụ mpụta ederede iji kwalite mgbasa ọkụ.

(3) Mgbanwe nha: Emepụtara site na millimeters (ihe nrụpụta ụlọ nyocha) ruo mita (kiln ụlọ ọrụ).

6. Nkwekọrịta na-adịgide adịgide

SiC tubes na-akwado omume ụlọ ọrụ enyi na enyi:

(1) Nchekwa ike: Ịrụ ọrụ ọkụ dị elu na-ebelata oriri ọkụ ọkụ ruo 20% ma e jiri ya tụnyere ọta ígwè.

(2) Mbelata mkpofu: Ogologo ndụ ọrụ na-ebelata ihe mkpofu site na ndochi anya.

(3) Mbelata nsi: Wepụ mkpa mkpuchi mkpuchi dị ize ndụ (dịka ọmụmaatụ, alloys dabere na nickel) na gburugburu ndị na-emebi emebi.

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.