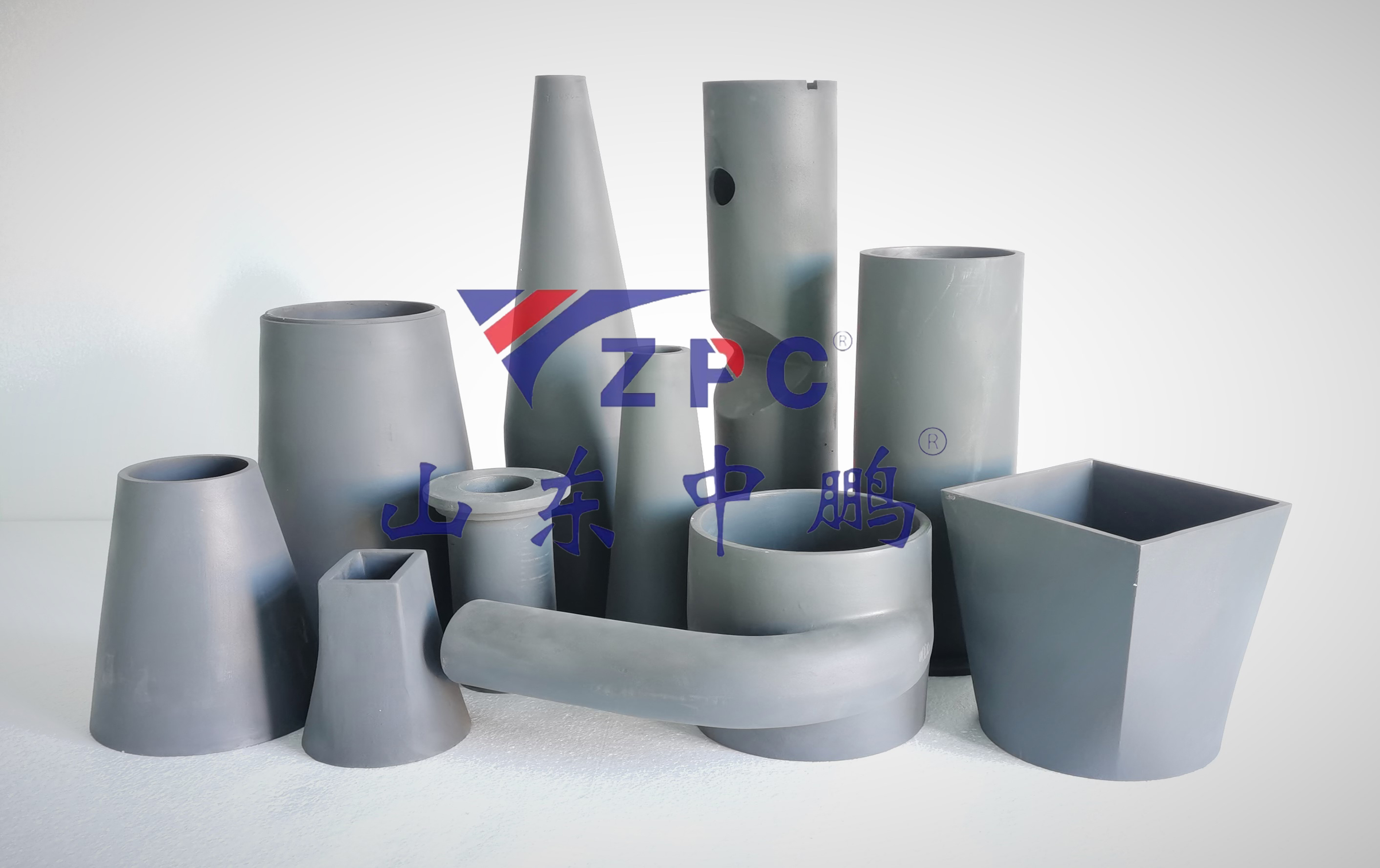

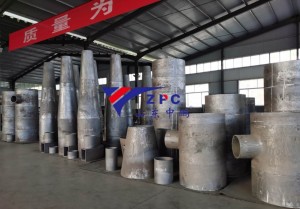

Silicon carbide seramiiki liners

Silicon carbide mkpuchi mkpuchi na-eguzogide

Akụkụ imewe nke Silicon Carbide (SiC) Liners na-eguzogide ọgwụ:

(1) Nhazi Ụzọ Na-asọ asọ

Ihe nrịbama dị larịị, nke dị larịị site na mbata ruo n'ọpụpụ na-ebelata nguzogide mmiri, na-eme ka SiC liners kwekọọ na ngwa ụlọ ọrụ dị iche iche.

(2) Advanced Atomization

A na-etinye usoro mmiri mmiri ka ọ bụrụ ụmụ irighiri mmiri dị mma site na nhụta tangential na-eji nwayọọ nwayọọ na-ebelata elu elu nke SiC liner, na-ahụ na nkesa ịgbasa otu.

(3) Kọmpat, Ọdịdị na-enweghị ihe mgbochi

Ọwa na-erute kwụ ọtọ, isi enweghị isi na-ewepụ ihe mgbochi dị n'ime, na-ebuli ntinye mmiri n'ime akụkụ ọkpọkọ akpọchiri ma na-egbochi mgbochi.

(4) Ụdị ịgbasa okpukpu abụọ maka ịrụ ọrụ nke ọma

Na-akwado ma usoro ịgba mmiri siri ike na cone oghere, na-enye akụkụ mkpuchi sara mbara na arụ ọrụ mgbochi mgbochi maka arụmọrụ dị elu.

Uru ndị isi ma e jiri ya tụnyere ihe ndị ọzọ:

(1) Nguzogide iyi na-enweghị atụ

Isi ike: SiC liners na-enweta ike Mohs nke 9.5 (vs. 8.0 maka alumina ceramics, 6.0 maka ígwè chromium dị elu), na-eme ka ha nwee ike iguzogide oke abrasive na-eyi na slurries Ngwuputa, ash coal, na powders metal.

Ogologo ndụ: Ndụ ọrụ karịrị 5-10 × ihe ọdịnala (dịka rọba ma ọ bụ polyurethane liners) na ngwa mmetụta dị elu dị ka igwe igwe bọọlụ ma ọ bụ nfuli slurry.

(2) Corrosion na Chemical Inertness

Acid/Alkali Nguzogide: Na-eguzogide sulfuric acid gbadoro ụkwụ (98%), sodium hydroxide (50%), na nnu a wụrụ awụ (dịka ọmụmaatụ NaCl-KCl na 800°C), ebe ọla na-emebi ngwa ngwa na polymers na-emebi emebi.

Mmetọ efu: elu anaghị arụ ọrụ na-eme ka ọ dị ọcha na mmepụta batrị nke semiconductor ma ọ bụ batrị lithium, n'adịghị ka ihe nchara ígwè na-adịkarị mfe ion leaching.

(3) Oke okpomoku kwụsie ike

Thermal Resilience: Na-arụ ọrụ na-aga n'ihu na 1,600 ° C (vs. alumina's 1,200°C limit) na obere mgbasawanye thermal (CTE: 4.0 × 10⁻⁶ / ℃), na-egbochi mgbawa na kilns ma ọ bụ ọkụ ọkụ.

Nguzogide okpomọkụ: Na-edobe iguzosi ike n'ezi ihe n'usoro n'okpuru mgbanwe okpomọkụ dị ngwa (dịka nkwụsị site na 1,000 Celsius ruo n'ime ụlọ), n'adịghị ka seramiki na-agbaji agbaji.

(4) Nrụpụta ike yana Nhazi dị arọ

Esemokwu dị ala: elu SiC na-egbu maramara (Ra <0.1 μm) na-ebelata nguzogide mmiri site na 30-50% na ndị na-ahụ maka ígwè siri ike, na-ebelata ụgwọ ọrụ ike.

Nchekwa arọ: Njupụta nke 3.1 g/cm³ (vs. steel's 7.8 g/cm³) na-eme ka nrụnye dị mfe ma na-akwado akụrụngwa dị fechaa na ikuku ikuku ma ọ bụ nhazi mkpanaka.

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.