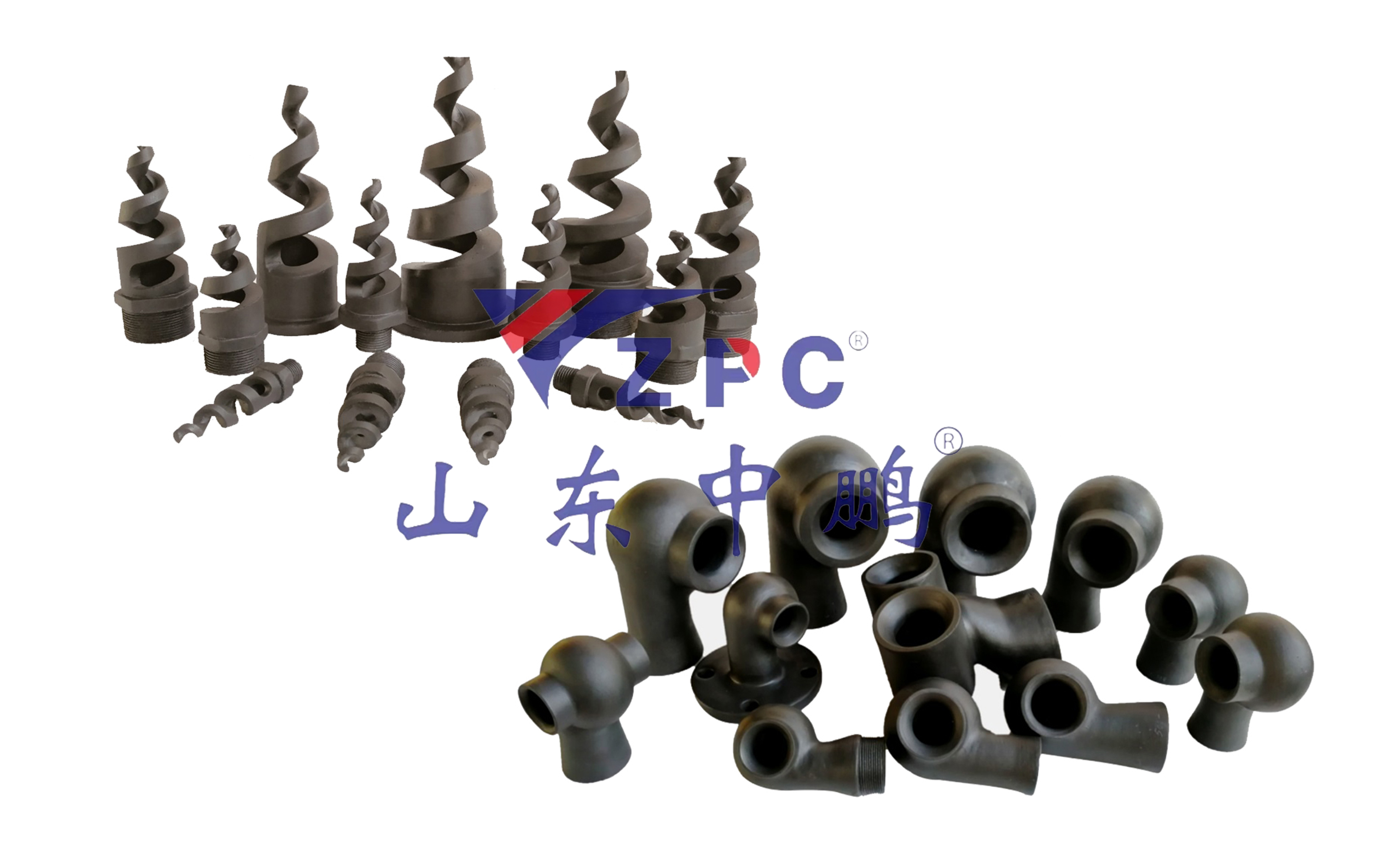

Dị ka akụkụ bụ isi nke sistemu ikuku gas dị ọcha,silicon carbide FGD Nozzlesna-ekere òkè dị mkpa na mpaghara mmepụta ihe dị ka ike ọkụ na metallurgy. Nke a silịkọn carbide seramiiki nozzle edozila ihe mgbochi teknụzụ nke igwe nozzles ọdịnala n'okpuru corrosion siri ike na ọnọdụ akwa akwa site na imepụta ihe ọhụrụ na ihe nrịbama ihe, na-emeziwanye arụmọrụ desulfurization nke ukwuu.

1, Material Njirimara tọrọ ntọala maka arụmọrụ

Isi ike nke Mohsceramics silicon carbideruru 9.2, nke abụọ na diamond, na njiri ike ya ji okpukpu atọ karịa nke seramiki alumina. Ihe owuwu kristal covalent a na-enye ihe ahụ ezigbo nguzogide abrasion, yana n'okpuru mmetụta nke slurry dị elu nwere kristal gypsum (ọnụego na-erute 12m / s), oke iyi elu bụ naanị 1/20 nke nozzles metal. Na gburugburu acid-base ọzọ na-agbanwe agbanwe na pH uru nke 4-10, ọnụ ọgụgụ nguzogide corrosion nke silicon carbide bụ ihe na-erughị 0.01mm / afọ, nke dị mma karịa 0.5mm / afọ nke 316L igwe anaghị agba nchara.

The thermal mgbasa ọnụọgụ ọnụọgụ nke ihe (4.0 × 10 ⁻⁶ / ℃) dị nso na nke ígwè, na ọ ka nwere ike ịnọgide na-enwe structural kwụsie ike n'okpuru a okpomọkụ iche nke 150 ℃. Silicon carbide ceramics kwadebere site na mmeghachi omume sintering usoro nwere a njupụta nke ihe karịrị 98% na a porosity nke na-erughị 0.5%, na-egbochi nke ọma structural mmebi nke ọkara infiltration kpatara.

2, Nkenke atomization usoro na eruba ubi akara

Nkesilicon carbide spiral nozzlena-abawanye ọsọ ọsọ nke slurry nke ukwuu, yana site na oghere nke ọma, ọ na-akụda slurry nkume n'ime obere ụmụ irighiri mmiri. Ọnụego mkpuchi mkpuchi oghere conical nke nwere oghere kpụrụ site na usoro a buru ibu, yana oge obibi nke ụmụ irighiri mmiri na ụlọ elu ahụ na-agbatị ruo 2-3 sekọnd, 40% dị elu karịa nke nozzles ọdịnala.

3. System dakọtara na engineering njikarịcha

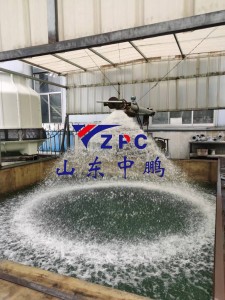

N'ụlọ elu ịgbasa ihe,silicon carbide FGD nozzlesA na-eji usoro chessboard mee ihe, na-enwe ohere nke 1.2-1.5 ugboro dayameta cone na-agba, na-eme akwa 3-5 nke mkpuchi. Nhazi a na-eme ka o doo anya na mkpuchi akụkụ nke ụlọ elu desulfurization karịrị 200%, na-eme ka kọntaktị zuru oke n'etiti gas flue na slurry. Site na ọnụ ọgụgụ ụlọ elu efu efu nke 3-5 m / s, a na-achịkwa mfu nrụgide usoro n'ime oke nke 800-1200 Pa.

Data arụmọrụ na-egosi na arụmọrụ desulfurization nke sistemu FGD site na iji silicon carbide nozzles ka kwụsiri ike karịa 97.5%, yana ọdịnaya mmiri nke ngwaahịa gypsum na-agbada n'okpuru 10%. Agbatịla usoro mmezi akụrụngwa site na ọnwa 3 maka nozzles metal ruo afọ 3, yana ọnụ ahịa nnọchi akụkụ ahụ belatara site na 70%.

Ngwa nke aFGD nozzlena-egosi mmụba site na ngwa ọrụ nchekwa gburugburu ruo kpọmkwem. Site na ntozu nke teknụzụ seramiiki ebipụta 3D, enwere ike imezu oke nhazi nke usoro ọwa mmiri n'ọdịniihu, nke nwere ike melite arụmọrụ atomization site na 15-20% ma kwalite teknụzụ ikuku dị ala iji banye ọkwa mmepe ọhụrụ.

Oge nzipu: Mar-24-2025