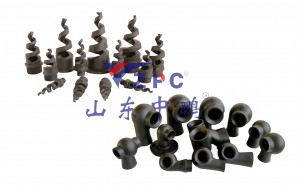

1. Nguzogide corrosion

FGD nozzlesna-arụ ọrụ na gburugburu ebe na-emebi emebi nke nwere sọlfọ oxides, chlorides, na kemịkalụ ndị ọzọ na-eme ihe ike. Silicon carbide (SiC) seramiiki na-egosiputa nguzogide corrosion pụrụ iche na ihe na-erughị 0.1% oke ọnwụ na pH 1-14 ngwọta (kwa ASTM C863 ule). Tụnyere igwe anaghị agba nchara (PREN 18-25) na nickel alloys (PREN 30-40), SiC na-edobe iguzosi ike n'ezi ihe n'usoro na-enweghị pitting ma ọ bụ nrụgide corrosion na-agbawa ọbụna na acid gbanyere mkpọrọgwụ na okpomọkụ dị elu.

2. Nkwụsi ike dị elu

Okpomọkụ na-arụ ọrụ na sistemụ desulfurization flue gas na-adịkarị 60-80 Celsius C yana spikes karịrị 120 Celsius. SiC seramiiki na-ejigide 85% nke ike ime ụlọ ya na 1400ºC, na-arụ ọrụ ceramik alumina (na-efunahụ 50% ike site na 1000 Celsius) na nchara na-eguzogide okpomọkụ. Nrụpụta ọkụ ya (120 W / m · K) na-eme ka ikpochapụ ọkụ na-arụ ọrụ nke ọma, na-egbochi nrụpụta okpomọkụ.

3. Yiri Nguzogide

Site na isi ike Vickers nke 28 GPa na mgbaji siri ike nke 4.6 MPa·m¹/², SiC na-egosipụta nguzogide oke mbuze megide ụmụ irighiri uyi ofufe (Mohs 5-7). Nnwale ubi na-egosi nozzles SiC na-ejigide <5% eyi mgbe awa ọrụ 20,000 gasịrị, ma e jiri ya tụnyere 30-40% iyi na alumina nozzles na ọdịda zuru oke nke ọla mkpuchi polymer n'ime awa 8,000.

4. Njirimara na-asọ asọ

Igwe anaghị agba nchara nke SiC na-ejikọ mmeghachi omume (n'akuku kọntaktị> 100°) na-eme ka mgbasa slurry ziri ezi na ụkpụrụ CV <5%. N'elu elu ya dị nro (Ra 0.2-0.4μm) na-ebelata nrụgide nrụgide site na 15-20% ma e jiri ya tụnyere ígwè nozzles, ebe ọ na-ejigide ọnụọgụ mwepu kwụsiri ike (± 1%) karịa ọrụ ogologo oge.

5. Nkwadebe Mfe

Inertness kemịkalụ SiC na-enye ohere ụzọ nhicha ike gụnyere:

- Jet mmiri dị elu (ihe ruru mmanya 250)

- Ultrasonic nhicha na ngwọta alkaline

- sterilization uzuoku na 150°C

Na-enweghị ihe ize ndụ nke nbibi elu nke a na-ahụkarị na igwe mkpuchi polymer ma ọ bụ mkpuchi mkpuchi.

6. Lifecycle Economics

Ọ bụ ezie na ụgwọ mbụ maka SiC nozzles bụ 2-3 × dị elu karịa ọkọlọtọ 316L igwe anaghị agba nchara, ndụ ọrụ afọ 8-10 ha (vs 2-3 afọ maka ọla) na-ebelata ugboro ugboro site na 70%. Mkpokọta ọnụ ahịa nwe na-egosi ego 40-60% n'ime afọ iri, na-enwekwa oge efu maka nrụzi n'ime ụlọ.

7. Ndakọrịta gburugburu ebe obibi

SiC na-egosipụta arụmọrụ na-enweghị atụ na ọnọdụ dị oke egwu:

- Nguzogide nnu nnu: 0% mgbanwe oke mgbe 5000hr ASTM B117 nyocha

- Acid igirigi arụ ọrụ: na-eguzogide 160°C H2SO4 vapors

- Mgbochi ujo na-ekpo ọkụ: na-adị ndụ 1000 ° C → 25 ° C menyụọ okirikiri

8. Ngwongwo na-eme ka ọ ghara imebi

Nhazi atomic covalent nke SiC na-emepụta elu na-adịghị arụ ọrụ yana ọnụego steepụ 80% dị ala karịa igwe ọzọ. Nnyocha kristal na-ekpughe na nkwụnye ego calcite na gypsum na-etolite agbụ na-esighị ike (adhesion <1 MPa) na SiC vesos> 5 MPa na ọla, na-eme ka mwepụ ọrụ dị mfe.

Nkà na ụzụ njedebe

Silicon carbide seramiiki na-apụta dị ka nhọrọ kacha mma maka FGD nozzles site na nyocha arụmọrụ zuru oke:

- 10× ogologo ndụ ọrụ ndụ karịa dara ọzọ

- Mbelata 92% na mmezi enweghị atụmatụ

- Mmelite 35% na nrụpụta SO2 site na usoro ịgbasa na-agbanwe agbanwe

- Nkwekọrịta zuru oke na ụkpụrụ ikuku ikuku EPA 40 CFR Nkebi 63

Site na usoro mmepụta ihe na-aga n'ihu dị ka mmiri mmiri-phase sintering na CVD mkpuchi, ọgbọ na-esote SiC nozzles na-emecha n'elu sub-micron na mgbagwoju anya geometries na-enwetabeghị na seramiki. Evolushọn teknụzụ a na-edobe silicon carbide dị ka ihe a na-ahọrọ maka sistemụ nhicha ikuku gas na-esote.

Oge nzipu: Mar-20-2025