ogologo ndụ DN100 otu direction vortex nozzle

Usoro BT FGD SiC Desulphuriztion nozzles

RBSC (SiSiC) desulphurization nozzles bụ akụkụ bụ isi nke sistemu ikuku gas desulphurization na osisi ike ọkụ.

Ọ bụ nnukwu ngwungwu otu ụzọ nozzle:

| Vortex Spray Nozzle Parameter List 涡流喷嘴技术参数表 | ||||||||||||||||||

| Nha (inch) | 喷雾角度 Igwe fesa | 连接方式 Ụdị njikọ | 入口直径 Dayameta mbata (mm) | 出口直径 Dayameta ọpụpụ (mm) | 压力 (ụlọ mmanya) 流量 (m3/h) Na-erute (m3/h) | |||||||||||||

| 60° | 90° | 120° | 螺纹连接 Ejiri eriri | 法兰 Flange | 缠绕连接 Ejikọtara | 0.2 mmanya | 0.3 mmanya | 0,5 mmanya | 0.7 mmanya | 1 mmanya | 1.5 mmanya | 2 mmanya | 3 mmanya | 4 mmanya | 7 mmanya | |||

| 1/2 | ※ | ※ | ※ | ※ | ※ | ※ | 11.1 | 7.9 | 0.44 | 0.54 | 0.7 | 0.82 | 0.98 | 1.2 | 1.38 | 1.68 | 1.98 | 2.58 |

| 9.9 | 0.58 | 0.71 | 0.92 | 1.09 | 1.32 | 1.62 | 1.86 | 2.28 | 2.64 | 3.48 | ||||||||

| 11.9 | 0.73 | 0.89 | 1.16 | 1.38 | 1.62 | 1.98 | 2.34 | 2.82 | 3.24 | 4.32 | ||||||||

| 13.9 | 1.03 | 1.26 | 1.62 | 1.92 | 2.28 | 2.82 | 3.24 | 3.96 | 4.56 | 6.06 | ||||||||

| 3/4 | ※ | ※ | ※ | ※ | ※ | ※ | 14.3 | 9.1 | 0.58 | 0.71 | 0.92 | 1.09 | 1.32 | 1.62 | 1.86 | 2.28 | 2.64 | 3.48 |

| 10.7 | 0.73 | 0.89 | 1.16 | 1.38 | 1.62 | 1.98 | 2.34 | 2.82 | 3.24 | 4.32 | ||||||||

| 12.3 | 0.88 | 1.07 | 1.38 | 1.62 | 1.98 | 2.4 | 2.76 | 3.42 | 3.9 | 5.16 | ||||||||

| 13.9 | 1.03 | 1.26 | 1.62 | 1.92 | 2.28 | 2.82 | 3.24 | 3.96 | 4.56 | 6.06 | ||||||||

| 16.7 | 1.44 | 1.8 | 2.34 | 2.76 | 3.24 | 4.02 | 4.62 | 5.64 | 6.54 | 8.64 | ||||||||

| 1 | ※ | ※ | ※ | ※ | ※ | ※ | 17.5 | 11.5 | 1.03 | 1.26 | 1.62 | 1.92 | 2.28 | 2.82 | 3.24 | 3.96 | 4.56 | 6.06 |

| 12.7 | 1.17 | 1.44 | 1.86 | 2.16 | 2.64 | 3.18 | 3.72 | 4.5 | 5.22 | 6.9 | ||||||||

| 14.3 | 1.32 | 1.62 | 2.1 | 2.46 | 2.94 | 3.6 | 4.14 | 5.1 | 5.88 | 7.8 | ||||||||

| 15.5 | 1.44 | 1.8 | 2.34 | 2.76 | 3.24 | 4.02 | 4.62 | 5.64 | 6.54 | 8.64 | ||||||||

| 17.5 | 1.74 | 2.16 | 2.76 | 3.3 | 3.9 | 4.8 | 5.52 | 6.78 | 7.86 | 10.4 | ||||||||

| 20.6 | 2.22 | 2.7 | 3,48 | 4.08 | 4.92 | 6 | 6.96 | 8.52 | 9,78 | 12.9 | ||||||||

| 1 1/4 | ※ | ※ | ※ | ※ | ※ | ※ | 21.4 | 14.3 | 1.44 | 1.8 | 2.34 | 2.76 | 3.24 | 4.02 | 4.62 | 5.64 | 6.54 | 8.64 |

| 16.3 | 1.74 | 2.88 | 2.76 | 3.3 | 3.9 | 4.8 | 5.52 | 6.78 | 7.86 | 10.4 | ||||||||

| 18.3 | 2.04 | 2.52 | 3.24 | 3.84 | 4.56 | 5.58 | 6.48 | 7.92 | 9.18 | 12 | ||||||||

| 20.2 | 2.34 | 2.94 | 3.72 | 4.38 | 5.22 | 6.42 | 7.38 | 9.06 | 10.4 | 13.8 | ||||||||

| 24.2 | 2.94 | 3.6 | 4.62 | 5.46 | 6.54 | 7.98 | 9.24 | 11.3 | 13.2 | 17.4 | ||||||||

| 1 1/2 | ※ | ※ | ※ | ※ | ※ | ※ | 27.8 | 17.5 | 2.34 | 2.94 | 3.72 | 4.38 | 5.22 | 6.42 | 7.38 | 9.06 | 10.4 | 13.8 |

| 21.8 | 2.94 | 3.6 | 4.62 | 5.46 | 6.54 | 7.98 | 9.24 | 11.3 | 13.2 | 17.4 | ||||||||

| 25.8 | 3.66 | 4.5 | 5.76 | 6.84 | 8.16 | 10 | 11.6 | 14.1 | 16.2 | 21.6 | ||||||||

| 28.6 | 4.38 | 5.4 | 6.69 | 8.22 | 9.72 | 12 | 13.8 | 17.1 | 19.5 | 25.8 | ||||||||

| 2 | ※ | ※ | ※ | ※ | ※ | ※ | 36.5 | 27 | 5.1 | 6.24 | 8.1 | 9.6 | 11.5 | 14.1 | 16.2 | 19.8 | 22.8 | 30 |

| 30.2 | 5.82 | 7.14 | 9.24 | 10.9 | 13.2 | 15.9 | 18.6 | 22.5 | 26.1 | 34.8 | ||||||||

| 32.9 | 6.6 | 8.04 | 10.4 | 12.3 | 14.7 | 18 | 20.7 | 25.5 | 29.4 | 39 | ||||||||

| 36.1 | 7.32 | 8.94 | 11.6 | 13.8 | 16.2 | 20.1 | 23.1 | 28.2 | 32.4 | 43.2 | ||||||||

| 39.7 | 8.76 | 10.7 | 13.8 | 16.5 | 19.5 | 24 | 27.6 | 34.2 | 39 | 51.6 | ||||||||

| 2 1/2 | ※ | ※ | ※ | ※ | ※ | ※ | 47.6 | 36.1 | 8.76 | 10.7 | 13.8 | 16.5 | 32.1 | 24 | 27.6 | 34.2 | 39 | 51.6 |

| 40.5 | 10.3 | 12.6 | 16.2 | 19.2 | 22.8 | 27.9 | 32.4 | 39.6 | 45.6 | 60.6 | ||||||||

| 44.1 | 11.7 | 14.4 | 18.6 | 21.9 | 26.1 | 32.1 | 37.2 | 45 | 52.2 | 69 | ||||||||

| 47.6 | 13.2 | 16.2 | 20.7 | 24.6 | 29.4 | 36 | 41.4 | 51 | 58.8 | 78 | ||||||||

| 50.8 | 14.7 | 18 | 23.1 | 27.3 | 32.4 | 40.2 | 46.2 | 56.4 | 65.4 | 86.4 | ||||||||

| 3 | ※ | ※ | ※ | ※ | ※ | ※ | 57.2 | 52.4 | 17.4 | 21.6 | 27.6 | 33 | 39 | 48 | 55.2 | 67.8 | 78.6 | 104 |

| 58.7 | 20.4 | 25.2 | 32.4 | 38.5 | 45.6 | 55.8 | 64.8 | 79.2 | 91.8 | 121 | ||||||||

| 4 | ※ | ※ | ※ | ※ | ※ | ※ | 79 2/5 | 50.8 | 21.9 | 27 | 34.8 | 41.4 | 49.2 | 60 | 69.6 | 85.2 | 97.8 | 130 |

| 59.1 | 25.5 | 31.5 | 40.2 | 48.3 | 57 | 70.2 | 81 | 99 | 115 | 151 | ||||||||

| 68.3 | 29.1 | 36 | 46.2 | 54.6 | 65.4 | 79.8 | 92.4 | 113 | 131 | 173 | ||||||||

| 74.6 | 33 | 40.5 | 52.2 | 61.5 | 73.8 | 90 | 104 | 127 | 147 | 194 | ||||||||

| 82.6 | 36.6 | 45 | 57.6 | 68.4 | 81.6 | 100 | 116 | 142 | 163 | 216 | ||||||||

| 92.1 | 40.2 | 49.5 | 63.6 | 75.6 | 90 | 110 | 127 | 156 | 180 | 238 | ||||||||

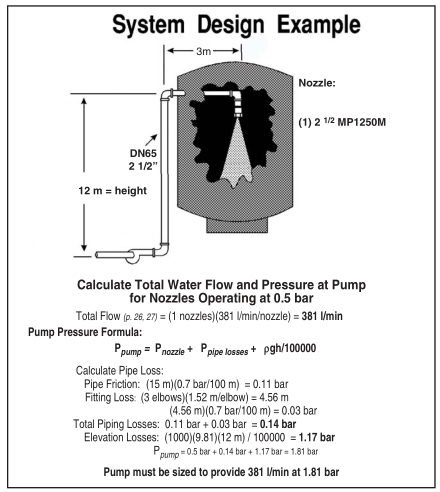

Na narị afọ nke 21 ụlọ ọrụ n'ụwa nile ga-eche ihe na-arịwanye elu na-achọ maka ịrụ ọrụ dị ọcha na nke ọma karị.

Ụlọ ọrụ ZPC na-agba mbọ ime akụkụ anyị iji chebe gburugburu ebe obibi. ZPC bụ ọkachamara n'ichepụta mmiri mmiri na ihe ọhụrụ teknụzụ maka ụlọ ọrụ na-achịkwa mmetọ. Site n'ịdị elu na-arụ ọrụ nke ọma na ntụkwasị obi, a na-enweta ihe ọkụkụ na-egbu egbu dị ala n'ikuku na mmiri anyị ugbu a. Nhazi nozzles dị elu nke BETE na-egosi mbelata ntinye nozzle, nkwalite nkesa usoro ịgba mmiri, ogologo ndụ nozzle, yana mmụba ntụkwasị obi na arụmọrụ.

Igwe mmiri a na-arụ ọrụ nke ọma na-arụpụta dayameta nke ntapu ntapu na nrụgide kacha ala na-ebute mbelata ihe achọrọ maka ịgbapụta mmiri.

ZPC nwere:

• Ahịrị kachasị obosara nke nozzles gburugburu gụnyere atụmatụ ndị na-egbochi mgbochi ka mma, akụkụ sara mbara, yana oke mmiri zuru oke.

• N'ụzọ zuru ezu nke ọkọlọtọ nozzle aghụghọ: tangential inlet, whirl disk nozzles, na fan nozzles, yana obere na elu-eru eru ikuku atomizing nozzles maka quench na akọrọ ihicha ngwa.

• Ike na-enweghị atụ iji chepụta, rụpụta na nyefee nozzles ahaziri iche. Anyị na gị na-arụkọ ọrụ iji mezuo iwu gọọmentị kacha sie ike. Anyị nwere ike izute ihe ị chọrọ pụrụ iche, na-enyere gị aka imeta arụmọrụ sistemụ kacha mma.

Nkọwa dị nkenke nke Mpaghara Scrubber FGD

Kwụsị:

N'akụkụ a nke scrubber, ọkụ ọkụ ọkụ na-ekpo ọkụ na-ebelata na okpomọkụ tupu abanye na pre-scrubber ma ọ bụ absorber. Nke a ga-echebe ihe ọ bụla na-ekpo ọkụ na-ekpo ọkụ na ihe nkwụnye ọkụ ma belata ụda gas, si otú ahụ na-amụba oge obibi na ihe nkwụnye ahụ.

Tupu-asachapụ:

A na-eji akụkụ a wepụ ihe irighiri ihe, chlorides, ma ọ bụ abụọ na gas flue.

Ọkụ:

Nke a na-abụkarị ụlọ elu na-efe efe na-emepe emepe nke na-ebute slurry na-ekpo ọkụ na kọntaktị na flue gas, na-ekwe ka mmeghachi omume kemịkal na-ekekọta SO 2 mee na sump.

mbukota:

Ụfọdụ ụlọ elu nwere ngalaba nkwakọ ngwaahịa. N'akụkụ a, a na-agbasa slurry na ngwugwu rụrụ arụ ma ọ bụ ahaziri iji mee ka elu dị na kọntaktị na gas flue.

Tray afụ:

Ụfọdụ ụlọ elu nwere efere gbawara agbawa n'elu akụkụ ihe na-ekpuchi ihe. A na-edobe slurry n'otu n'otu na efere a, nke abụọ na-eme ka ikuku gas dị nhata ma na-enye ebe dị elu na kọntaktị na gas.

Ihe mkpochapụ alụlụ:

Sistemu FGD dị mmiri mmiri na-ewepụta pasentị ụfọdụ nke ụmụ irighiri mmiri dị oke mma nke a na-ebufe site na ngagharị nke flue gas na-aga na ọpụpụ ụlọ elu. Ihe na-ekpochapụ alụlụ bụ usoro vanes gbagọrọ agbagọ nke na-ejide ma na-eme ka ụmụ irighiri mmiri dị na ya, na-enye ohere ka eweghachi ha na sistemụ. Iji nọgide na-arụ ọrụ nke ọma iwepụ mmiri mmiri dị elu, a ga-ehichapụkwa vanes alụlụ alụlụ ọgụ kwa oge.

Oghere cone Tangential Whirl TH Series

Nhazi

• Usoro nozzles nke akụkụ aka nri site na iji ntinye tangential iji mepụta ikuku

• mgbochi mgbochi: nozzles enweghị akụkụ dị n'ime

• ihe owuwu: ihe nkedo otu akụkụ

• njikọ: flanged ma ọ bụ nwanyị, NPT ma ọ bụ BSP eri

Njirimara ịgbasa

• Oke ọbụna ịgba nkesa

• Ụdị ịgbasa: cone oghere

• Akụkụ ịgbasa: 70° ruo 120°

• Ọnụego ọsọ: 5 ruo 1500 gpm (15.3 ruo 2230 l / min)

Na pụrụ iche nha izute gị kpọmkwem nkọwa

Cone Spiral Nozzle zuru ezu

ST, STXP, TF, usoro TFXP

Nhazi

• Ntụpọ gburugburu gburugburu

• Ọsọ ọsọ dị elu

• Ịrụ ọrụ ike dị elu

• mgbochi mgbochi: ihe owuwu nke otu na-enweghị akụkụ dị n'ime

• ihe owuwu: nkedo nke otu, abụọ ma ọ bụ atọ

• njikọ: NPT ma ọ bụ BSP eri nwoke ọkọlọtọ ọkọlọtọ, nwanyị eri na flanged njikọ dị site pụrụ iche iji

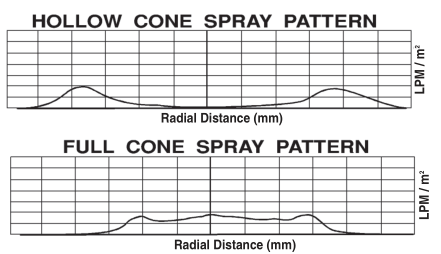

Njirimara ịgbasa

• Atọmịka dị mma

• Ụkpụrụ ịgba: cone zuru ezu na oghere

• Ọnụego ntinye: 0.5 ruo 3320 gpm (2.26 ruo 10700 l / min) ọnụego dị elu dị elu.

Ihe: Silicon Carbide Reaction Bonded (RBSC)

Nha: 0.75 inch, 1.2 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 3.5 inch, 4 inch, 4.5 inch nakwa dị ka ihe ị chọrọ.

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.