Hot Selling for Infrared Paint Heaters - Wear resistant and corrosion resistant ceramic pipe elbow – ZhongPeng

Hot Selling for Infrared Paint Heaters - Wear resistant and corrosion resistant ceramic pipe elbow – ZhongPeng Detail:

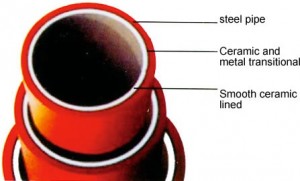

Silicon Carbide Ceramic lined pipe are mainly used in the field of wear resistance. Usually the Ceramic lined pipe is mounted on the steel pipe, we can provide customized drawings of the finished product.

Product Advantages:

Abrasion resistance: SiC – Moh’s hardness is 9~9.2, about 40 times stronger than ordinary pipes under the same conditions

Scrub resistance: can withstand the scrubbing wear of large granular materials without damage

Good fluidity: smooth surface, ensuring free flow of material without clogging

Low maintenance costs: Superior wear resistance reduces maintenance frequency and maintenance costs.

Inner Diameter: MM, thickness 6-35MM(We can produce as your demands and drawings!)

Sample:Free existing sample for checking size and quality

Product lead time: 10 -15 days after receipt of deposit

FOB port: Qingdao port

Related products:Wear resistant SiC ceramic tube. Wear resistant SiC ball. Wear resistant Silicon carbide lining, elbow, spigot

- Our technical staff can assist in the design of drawings according to customers’ intention;

- We are online 24 hours a day and provide technical services free of charge at any time.

Product detail pictures:

Related Product Guide:

SiC FGD desulphurization nozzles

Industrail SiC Crucibles and Saggers – Keep Your Business Warm

Hot Selling for Infrared Paint Heaters - Wear resistant and corrosion resistant ceramic pipe elbow – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.