Raws li lub hauv paus tseem ceeb ntawm niaj hnub flue gas purification systems,Silicon Carbide FGD Nozzlesua lub luag haujlwm tseem ceeb hauv kev lag luam xws li thermal zog thiab metallurgy. Qhov no silicon carbide ceramic nozzle tau ua tiav cov kev daws teeb meem ntawm cov tsoos hlau nozzles nyob rau hauv muaj zog corrosion thiab siab hnav tej yam kev mob los ntawm kev tsim qauv tsim thiab cov ntaub ntawv breakthroughs, zoo heev txhim kho desulfurization efficiency.

1 、 Cov khoom siv nteg lub hauv paus rau kev ua haujlwm

Mohs hardness ntawmsilicon carbide ceramicsmus txog 9.2, thib ob tsuas yog pob zeb diamond, thiab nws cov pob zeb tawg yog peb npaug ntawm alumina ceramics. Qhov no covalent siv lead ua qauv endows cov khoom uas muaj kev puas tsuaj zoo heev, thiab nyob rau hauv cov kev cuam tshuam ntawm high-speed slurry uas muaj gypsum crystals (ntev npaum li cas mus txog 12m / s), qhov nto hnav tus nqi tsuas yog 1/20 ntawm cov hlau nozzles. Nyob rau hauv ib puag ncig acid-base alternating ib puag ncig nrog tus nqi pH ntawm 4-10, qhov kev tiv thaiv corrosion ntawm silicon carbide tsawg dua 0.01mm / xyoo, uas zoo dua li 0.5mm / xyoo ntawm 316L stainless hlau.

Lub thermal expansion coefficient ntawm cov khoom (4.0 × 10 ⁻⁶ / ℃) yog ze rau ntawm cov hlau, thiab nws tseem tuaj yeem tswj cov qauv kev ruaj ntseg hauv qhov kub sib txawv ntawm 150 ℃. Silicon carbide ceramics npaj los ntawm cov txheej txheem sintering muaj qhov ntom ntawm ntau dua 98% thiab qhov porosity tsawg dua 0.5%, tiv thaiv cov qauv kev puas tsuaj los ntawm nruab nrab infiltration.

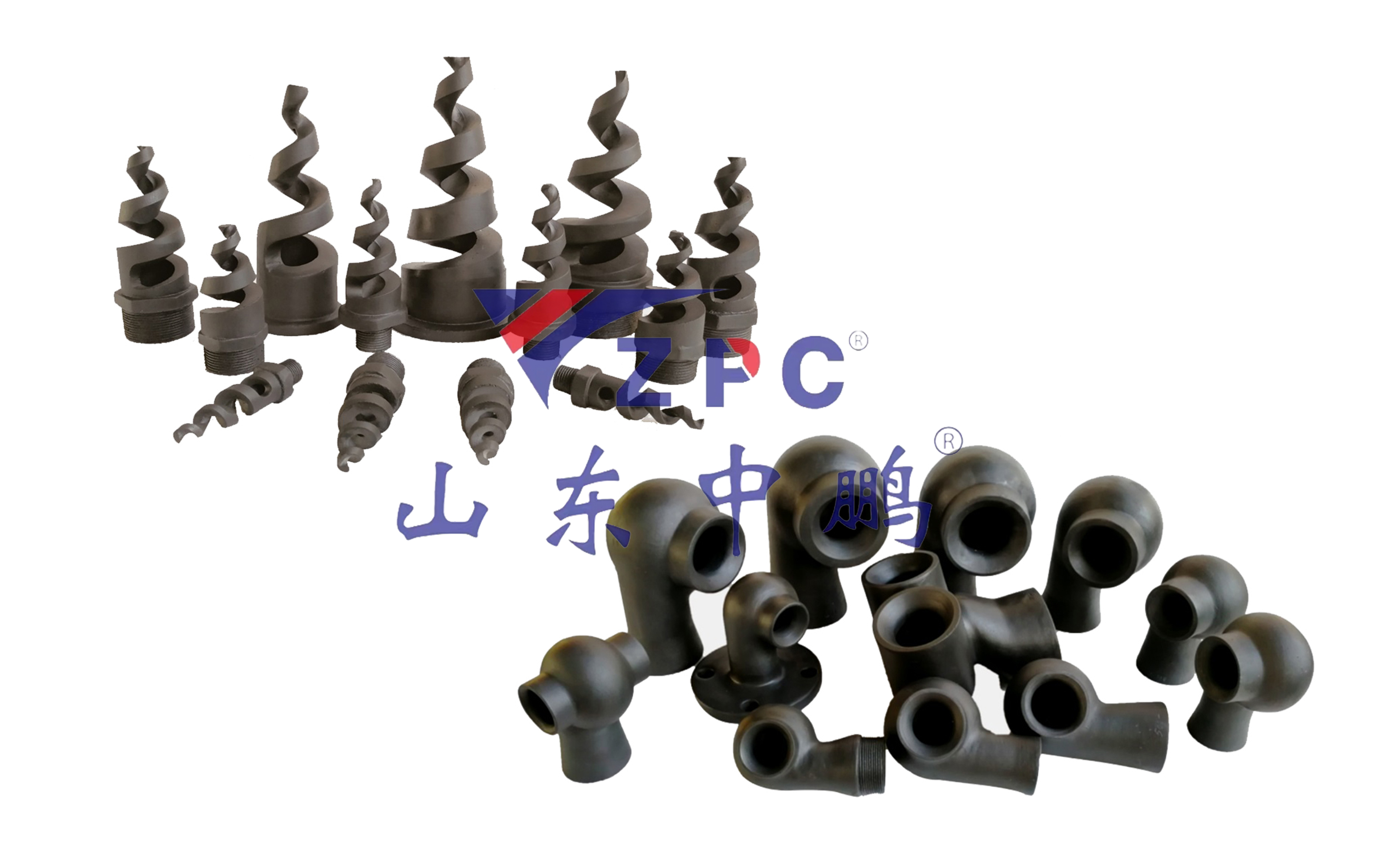

2 、 Precision atomization mechanism thiab ntws teb tswj

Covsilicon carbide kauv nozzleNws ua rau kom lub swirling ceev ntawm slurry, thiab nrog lub qhov hluav taws xob meej aperture, nws lov cov limestone slurry rau hauv me me thiab zoo li cov tee dej. Lub hollow conical spray teb qhov kev pab them nqi tsim los ntawm cov qauv no yog loj heev, thiab lub sij hawm nyob rau hauv cov tee dej nyob rau hauv lub pej thuam yog ncua mus rau 2-3 vib nas this, 40% siab tshaj ntawm cov tsoos nozzles.

3 、 Kev sib xyaw ua ke thiab engineering optimization

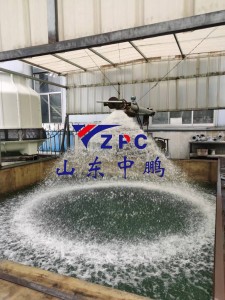

Nyob rau hauv ib qho tshuaj tsuag ntauwd,silicon carbide FGD nozzlesteem rau hauv chessboard yam yog siv, nrog rau qhov sib nrug ntawm 1.2-1.5 npaug ntawm cov tshuaj tsuag lub khob hliav qab, tsim 3-5 txheej ntawm overlay. Qhov kev npaj no ua kom ntseeg tau tias qhov kev tiv thaiv kab ke ntawm cov desulfurization ntau tshaj 200%, ua kom muaj kev sib cuag txaus ntawm cov roj flue thiab cov slurry. Nrog rau qhov khoob ntauwd ntws ntawm 3-5 m / s, qhov system siab poob yog tswj nyob rau hauv thaj tsam ntawm 800-1200 Pa.

Cov ntaub ntawv ua haujlwm qhia tau hais tias qhov kev ua haujlwm ntawm desulfurization ntawm FGD system siv silicon carbide nozzles nyob ruaj khov ntawm ntau dua 97.5%, thiab cov ntsiab lus noo ntawm gypsum los ntawm cov khoom raug txo kom qis dua 10%. Cov khoom siv tu lub voj voog tau txuas ntxiv los ntawm 3 lub hlis rau cov hlau nozzles mus rau 3 xyoos, thiab cov nqi ntawm cov khoom hloov pauv tau txo qis los ntawm 70%.

Kev siv ntawm noFGD nozzlemarks ib tug leap los ntawm nws kim heev mus rau meej ib puag ncig tiv thaiv cov cuab yeej. Nrog rau kev loj hlob ntawm 3D tshuab luam ntawv ceramic, topology optimization tsim ntawm ntws channel qauv yuav pom tau yav tom ntej, uas tuaj yeem txhim kho atomization efficiency los ntawm 15-20% thiab txhawb ultra-low emission technology kom nkag mus rau theem tshiab ntawm txoj kev loj hlob.

Post lub sij hawm: Mar-24-2025