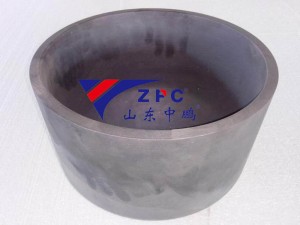

Reaction bonded silicon carbidecruciblessawv cev rau kev ua tiav hauv cov thev naus laus zis refractory, muab kev ua haujlwm tsis sib xws hauv qhov chaw thermal heev. Cov thawv ntim khoom siv tau zoo no tau dhau los ua qhov tseem ceeb thoob plaws metallurgy, precision casting, mechanical engineering, thiab chemical processing industries, xa cov kev ua haujlwm zoo tshaj plaws uas cov khoom siv tsoos luv luv.

Core Technical Advantages

RBSC crucibles outperform pa alumina thiab graphite counterparts los ntawm:

- Tshwj xeeb thermal conductivity (120-150 W / m·K ntawm 1000 ° C)

- Ultra-low thermal expansion coefficient (4.5 × 10⁻⁶ / K)

- Thermal shock resistance withstanding 50+ ceev cua txias voj voog (1600 ° C → 25 ° C)

- Acid / alkali corrosion kuj (pH 0-14 compatibility)

- Oxidation stability nyob rau hauv huab cua mus txog 1650 ° C

Metallurgical Mastery

Nyob rau hauv alloy steel ntau lawm thiab cov hlau tsis-ferrous smelting (txhuas, tooj liab, zinc), RBSC crucibles pab:

- 20-30% sai melting tus nqi los ntawm optimized hloov tshav kub

- 99.95% hlau purity txij nkawm ntawm cov khoom tsis-reactive

- Txo cov slag tsim los ntawm minimized thermal stratification

- Kev pab lub neej ntev (3-5 × ntev dua av nplaum-graphite crucibles)

Precision Casting & Mechanical Applications

Lub crucibles 'cov khoom siv tshwj xeeb txhawb kev xav tau kev lag luam:

- Kev ruaj ntseg ntawm cov qauv hauv qab 15-20 MPa cov neeg kho tshuab kev ntxhov siab

- Kev ruaj ntseg zoo ib yam (± 0.1% kev hloov pauv ntawm 1500 ° C)

- Kev ua kom tsis muaj paug paug rau aerospace-qib Cheebtsam

- Txhim khu kev ua tau zoo hauv centrifugal casting tshuab

Chemical Processing Excellence

RBSC crucibles daws cov teeb meem tseem ceeb hauv kev tsim tshuaj lom neeg:

- Muaj kev nyab xeeb ntawm cov ntsev ntsev (xws li NaOH, KNO₃)

- Kev ua haujlwm ruaj khov hauv sulfidation / chlorination cov tshuaj tiv thaiv

- Corrosion tiv thaiv HF txog 800 ° C

- Purity preservation nyob rau hauv tsawg lub ntiaj teb lub ntsiab extraction

Kev Lag Luam Kev Lag Luam

Thaum cov nqi pib yog 40-60% siab dua li ib txwm crucibles, RBSC cov kev daws teeb meem xa:

- 70% txo qhov hloov zaus

- 25-35% kev txuag hluav taws xob los ntawm kev txhim kho thermal efficiency

- 90% cov khoom siv rov ua dua tshiab ntawm thermal reclamation

- Zero tu yuav tsum

Kev lag luam-Specific Innovations

1. Titanium alloy ntau lawm

- Withstands reactive Ti melts ntawm 1700 ° C

- Tiv thaiv cov pa roj carbon monoxide

2. Roj teeb khoom Synthesis

- Pab kom zoo li LiCoO₂ cathode ua

- Resistant lithium ntsev corrosion

3. Semiconductor Crystal Loj hlob

-Txhim kho lub tshuab nqus tsev siab ultra-siab compatibility

- Tshem tawm cov kab mob silicon carbide

Yav tom ntej-Forward Design

Niaj hnub nimno RBSC crucibles suav nrog cov yam ntxwv siab heev:

- Gradient porosity qauv rau tswj roj permeability

- Nanoscale nto txheej txheej txhim kho slag kuj

- Embedded thermal sensors rau kev saib xyuas cov txheej txheem

Los ntawm kev soj ntsuam-scale kev tshawb fawb mus rau kev lag luam loj, cov tshuaj tiv thaiv-bonded silicon carbide crucibles txuas ntxiv redefine thermal ua peev xwm. Lawv cov kev sib xyaw ua ke ntawm thermal, mechanical, thiab chemical zog ua rau lawv ua qhov kev xaiv rau cov kev siv kub-kub tom ntej, tsav kev ua tau zoo thiab kev txhim kho zoo thoob plaws ntau qhov kev tsim khoom siab heev.

Post lub sij hawm: Mar-20-2025