Silicon carbide (SiC) ceramicspaub txog lawv lub zog zoo kawg nkaus, ua haujlwm kub, thiab kav ntev. Cov khoom no ua rau lawv zoo tagnrho rau siv nyob rau hauv ib puag ncig nyuaj, xws li aerospace xyaw lossis cov tshuab ua haujlwm. Tab sis yuav ua li cas raws nraim cov ntaub ntawv qib siab no tsim? Cia peb rhuav tshem cov txheej txheem ib kauj ruam.

1.Raw Material Preparation

Nws tag nrho pib nrog high-purity silicon carbide hmoov. Xav txog qhov no yog "hmoov" rau ci ceramic "ncuav mog qab zib." Txhawm rau txhim kho cov khoom kawg, cov khoom siv me me - zoo li aluminium oxide lossis boron compounds - yog sib xyaw ua ke.

2. Shaping lub Ceramic

Tom qab ntawd cov hmoov yog hloov mus rau hauv daim ntawv moldable. Muaj ob txoj hauv kev yog siv:

Nias: Cov hmoov yog compressed rau hauv ib qho kev siv lub siab, zoo ib yam li compacting snow rau hauv ib lub snowball.

Txhaj Molding: Cov hmoov yog tov nrog ib ntus binder (xws li siv quav ciab) los tsim ib qho kev sib xyaw ua khob noom cookie, uas yog txhaj rau hauv pwm rau cov duab nyuaj.

Nyob rau theem no, cov khoom tseem tsis yooj yim - zoo li cov duab puab xuab zeb qhuav - thiab yuav tsum tau "ci" kom muaj zog.

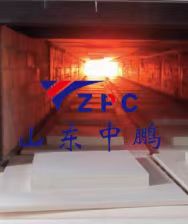

3. Cov txheej txheem Sintering

Qhov no yog qhov ua khawv koob tshwm sim. Cov zoo li cov ceramic yog rhuab nyob rau hauv ib lub qhov cub tshwj xeeb ntawm qhov kub siab heev (feem ntau siab dua 1,800 ° C). Thaum sintering, ob yam tseem ceeb tshwm sim:

Particle Bond: Cov nplej silicon carbide loj hlob los ze zog, tshem tawm qhov khoob thiab tsim cov qauv khoom.

Additives Ua Haujlwm: Cov khoom sib txuas ntxiv yaj me ntsis, tsim kom muaj "choj" ntawm cov khoom los txhim kho toughness.

Ib puag ncig hauv lub cub tawg yog ua tib zoo tswj - qee zaum muaj cov pa roj inert - txhawm rau tiv thaiv qhov tsis xav tau.

4. Tiav kov

Tom qab sintering, cov ceramic yuav raug kho ntxiv los kho nws cov kev ua tau zoo:

Polishing: Rau daim ntawv thov uas yuav tsum tau du nto (xws li, seals los yog bearings).

Txheej: Ib txheej tiv thaiv nyias (xws li silicon nitride) tuaj yeem muab ntxiv los txhawb kev hnav tsis kam.

Machining: Precise txiav los yog drilling kom tiav qhov ntev.

Vim li cas qhov txheej txheem no tseem ceeb

Cov lus zais rau silicon carbide lub zog nyob rau hauv yuav ua li cas nws cov atoms daim ntawv cog lus thaum sintering. Cov txheej txheem kub kub ua kom muaj kev sib txuas ntawm cov silicon-carbon bonds muaj zog, uas tiv taus tshav kub, corrosion, thiab kev ntxhov siab ntawm lub cev. Cov khoom siv ntxiv thiab kev tswj qhov kub thiab txias kom ntseeg tau tias cov khoom kawg tsis yog ib qho nyuaj tab sis kuj tawv txaus los tiv thaiv kev tawg.

Daim Duab Loj

Los ntawm kev txiav-ntug turbines mus rau kev tswj cov pa phem, silicon carbide ceramics ua lub luag haujlwm tseem ceeb hauv kev siv tshuab niaj hnub. Thaum cov txheej txheem tsim khoom yog qhov nyuaj, nws yog qhov ua tib zoo sib npaug ntawm kev tshawb fawb thiab kev tsim vaj tsev uas hloov cov hmoov yooj yim rau hauv cov khoom muaj peev xwm tiv taus qhov hnyav tshaj plaws.

Raws li kev tshawb fawb tau ua tiav, cov txheej txheem tshiab - zoo li 3D luam ntawv ntawm ceramics - tau tshwm sim, cog lus tias yuav siv ntau yam tshiab rau cov khoom siv tshwj xeeb no.

Lub sij hawm xa tuaj: Mar-19-2025