Silicon carbide thiab silicon nitride tsis zoo wettability nrog molten hlau. Dhau li ntawm qhov infiltrated los ntawm magnesium, npib tsib xee, chromium alloy thiab stainless hlau, lawv tsis muaj wettability rau lwm yam hlau, yog li lawv muaj zoo heev corrosion kuj thiab yog dav siv nyob rau hauv aluminium electrolysis kev lag luam.

Nyob rau hauv daim ntawv no, corrosion kuj ntawm recrystallized silicon carbide R-SiC thiab silicon nitride bonded silicon carbide Si3N4-SiC nyob rau hauv kub-circulating Al-Si alloy melts yog soj ntsuam los ntawm ntau lub latitudes.

Raws li kev sim cov ntaub ntawv ntawm 9 lub sij hawm ntawm thermal cycling ntawm 1080h nyob rau hauv 495 ° C ~ 620 ° C aluminium-silicon alloy yaj, cov kev soj ntsuam nram qab no tau txais.

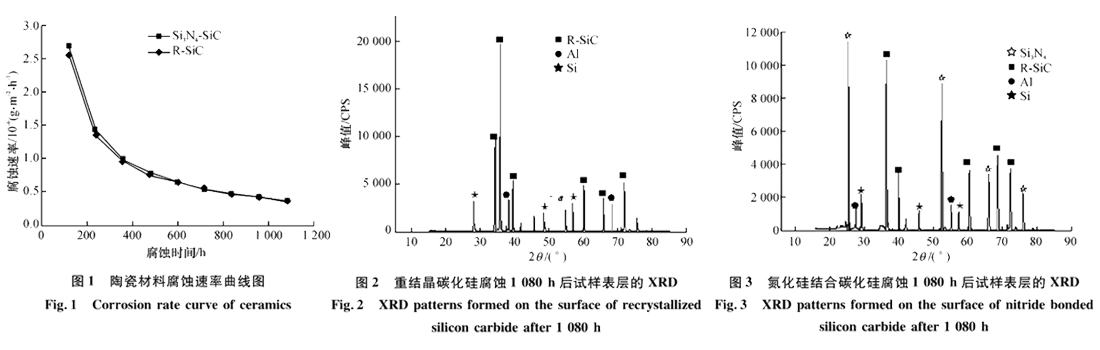

Cov qauv R-SiC thiab Si3N4-SiC tau nce nrog lub sijhawm corrosion thiab tus nqi corrosion txo. Tus nqi corrosion raws li logarithmic kev sib raug zoo ntawm attenuation. (daim duab 1)

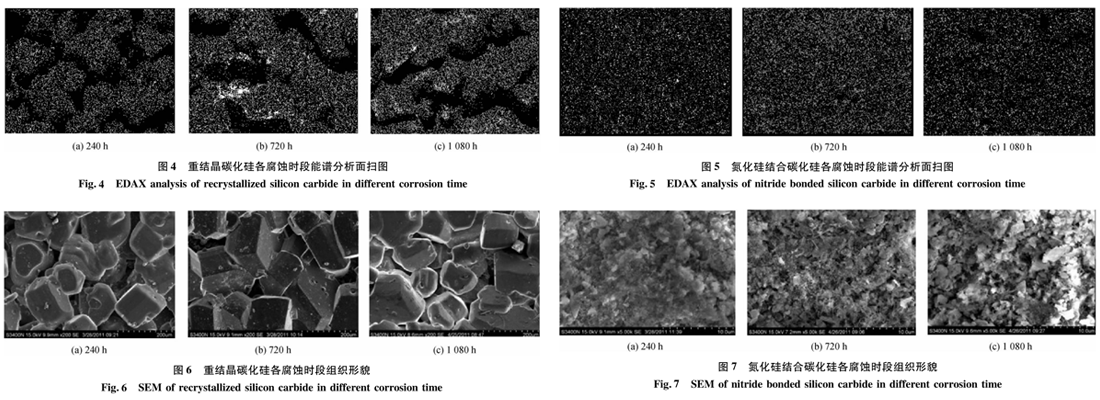

Los ntawm lub zog spectrum tsom xam, cov qauv R-SiC thiab Si3N4-SiC lawv tus kheej tsis muaj txhuas-silicon; nyob rau hauv tus qauv XRD, ib tug tej yam nyiaj ntawm txhuas-silicon ncov yog cov nto-residual txhuas-silicon alloy. (Daim duab 2 – Daim duab 5)

Los ntawm SEM tsom xam, raws li lub sij hawm corrosion nce, tag nrho cov qauv ntawm R-SiC thiab Si3N4-SiC cov qauv yog xoob, tab sis tsis muaj kev puas tsuaj. (Daim duab 6 – Daim duab 7)

Qhov ntom ntom ntom σs / l> σs / g ntawm qhov sib cuam tshuam ntawm cov kua txhuas txhuas thiab cov ceramic, lub kaum sab xis θ ntawm qhov sib cuam tshuam yog> 90 °, thiab qhov cuam tshuam ntawm cov kua txhuas thiab cov ntaub ntawv ceramic tsis ntub.

Yog li ntawd, R-SiC thiab Si3N4-SiC cov ntaub ntawv zoo heev hauv corrosion tiv thaiv aluminium silicon yaj thiab muaj qhov sib txawv me ntsis. Txawm li cas los xij, tus nqi ntawm Si3N4-SiC cov ntaub ntawv yog qhov tsawg thiab tau ua tiav zoo rau ntau xyoo.

Post lub sij hawm: Dec-17-2018