High definition Waste Oil Nozzle For Boiler - Manufacturer (factory) of Silicon Cabide bricks, plates, tiles – ZhongPeng

High definition Waste Oil Nozzle For Boiler - Manufacturer (factory) of Silicon Cabide bricks, plates, tiles – ZhongPeng Detail:

The Silicon Carbide tolerates a wide range of acids and alkalis. And with excellent performance of high strength, high hardness, high wear resistance, high temperature resistance, corrosion resistance. The different kinds of shapes of special parts are suitable for mining, petrochemical, metallurgical manufacturing, aerospace and nuclear industries, such as a specific environment. We can make any sizes provided according to the customer request.

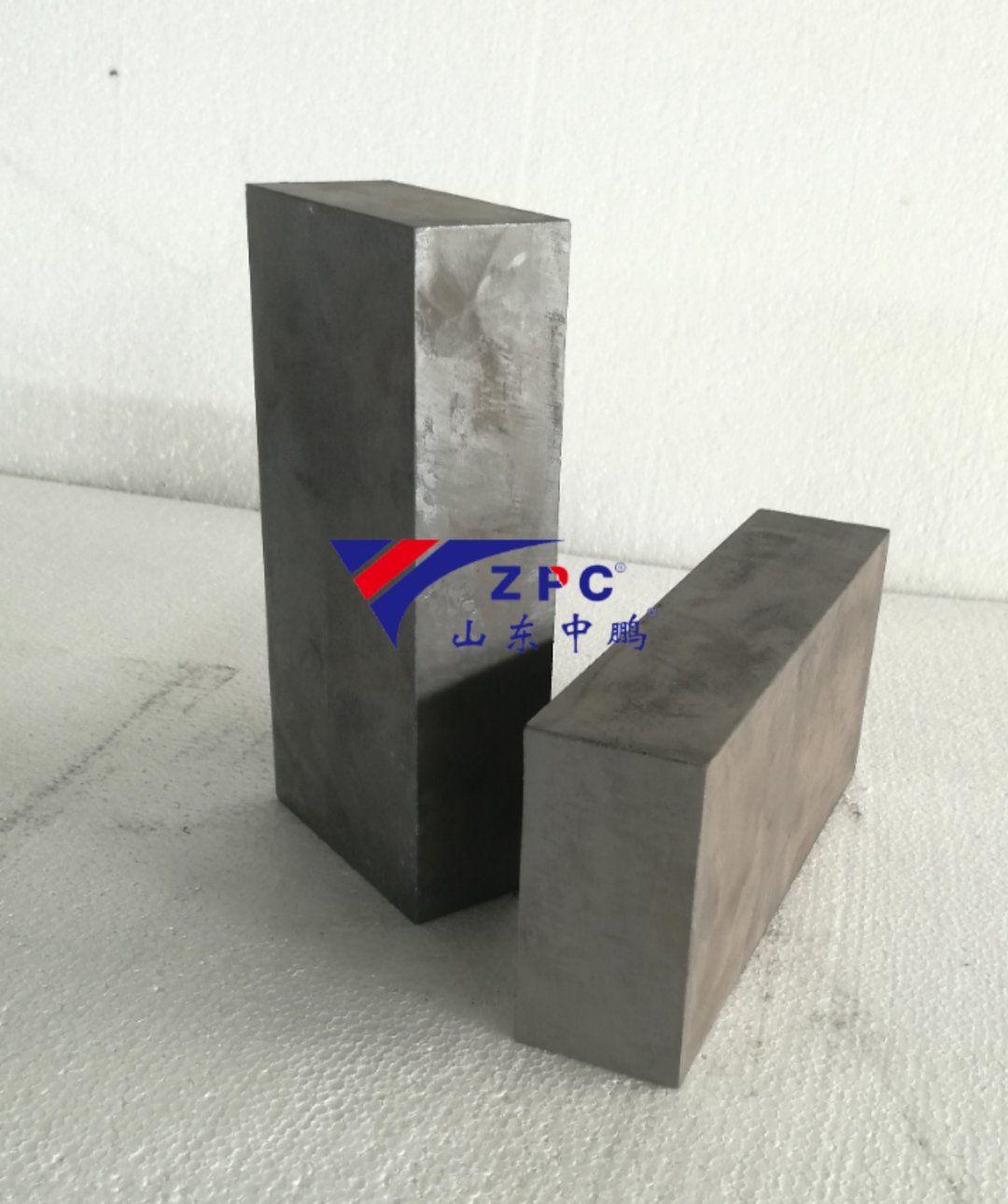

Wear resistance, high temperature strength and corrosion resistance make Reaction Bonded SiC an ideal material for wear components, such as pipe liners, bricks, tiles, blocks, etc.

| Physical characters | Unit | Properties |

| SIC content | % | 95-88 |

| Free Si | % | 5~12 |

| Bulk density | g/cm3 | >3.02 |

| Porosity | % | <0.1 |

| Hardness | Kg/mm2 | 2400 |

| Coefficient of bending strength at 20 degrees Celsius | Mpa | 260 |

| Coefficient of bending strength at 1200 degrees Celsius | Mpa | 280 |

| Modulus of elasticity at 20 Degrees Celsius | Gpa | 330 |

| Fracture toughness | Mpa*m1/2 | 3.3 |

| Coefficient of thermal conductivity at 1200 degrees Celsius | W/m.k |

45 |

| Coefficient of thermal expansion at 1200 degrees Celsius | 10-6mm/mmK |

4.5 |

| Coefficient of heat radiation | <0.9 | |

| Max. Working temperature | ºC | <1380 |

Silicon Carbide SiC (SiSiC/RBSiC) Features:

Abrasion / Corrosion resistance

Excellent thermal shock characteristics

Excellent oxidation resistance

Good dimensional control of complex shapes

High thermal conductivity

Improved performance

Longer life between replacement / rebuilds

Resistance to corrosion

Superior Resistance to wear

Strength at high temperature up to 1380°C

Silicon carbide plates applications:

SiC silicon carbide plate and tiles is a type of special ceramic plate are widely used in many industrial productions:

Mining Industry, Machine Industry, Chemical Industry, Crystallite Glass Industry, Magnetic Materials Industry, Metallurgy, Metallurgy Industry, Paper Industry, Petroleum Industry, kiln,etc.

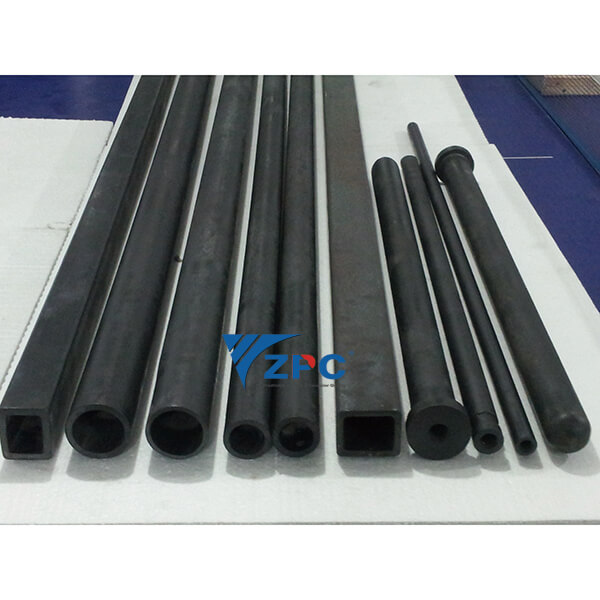

Customized silicon carbide products, shape available: plates, bricks, tiles, radian plate, screw, plain plate, straight pipe, tee pipes, ring, elbow, cone cyclone and so on.

Product detail pictures:

Related Product Guide:

Wear resistance block, plates and inner lining

Relationship Between Mechanical Properties and Wear Resistance of Alumina-Zirconia Ceramic Composites

High definition Waste Oil Nozzle For Boiler - Manufacturer (factory) of Silicon Cabide bricks, plates, tiles – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.