E hoʻohana i ka paipu ceramic carbide kūpaʻa a me ka corrosion

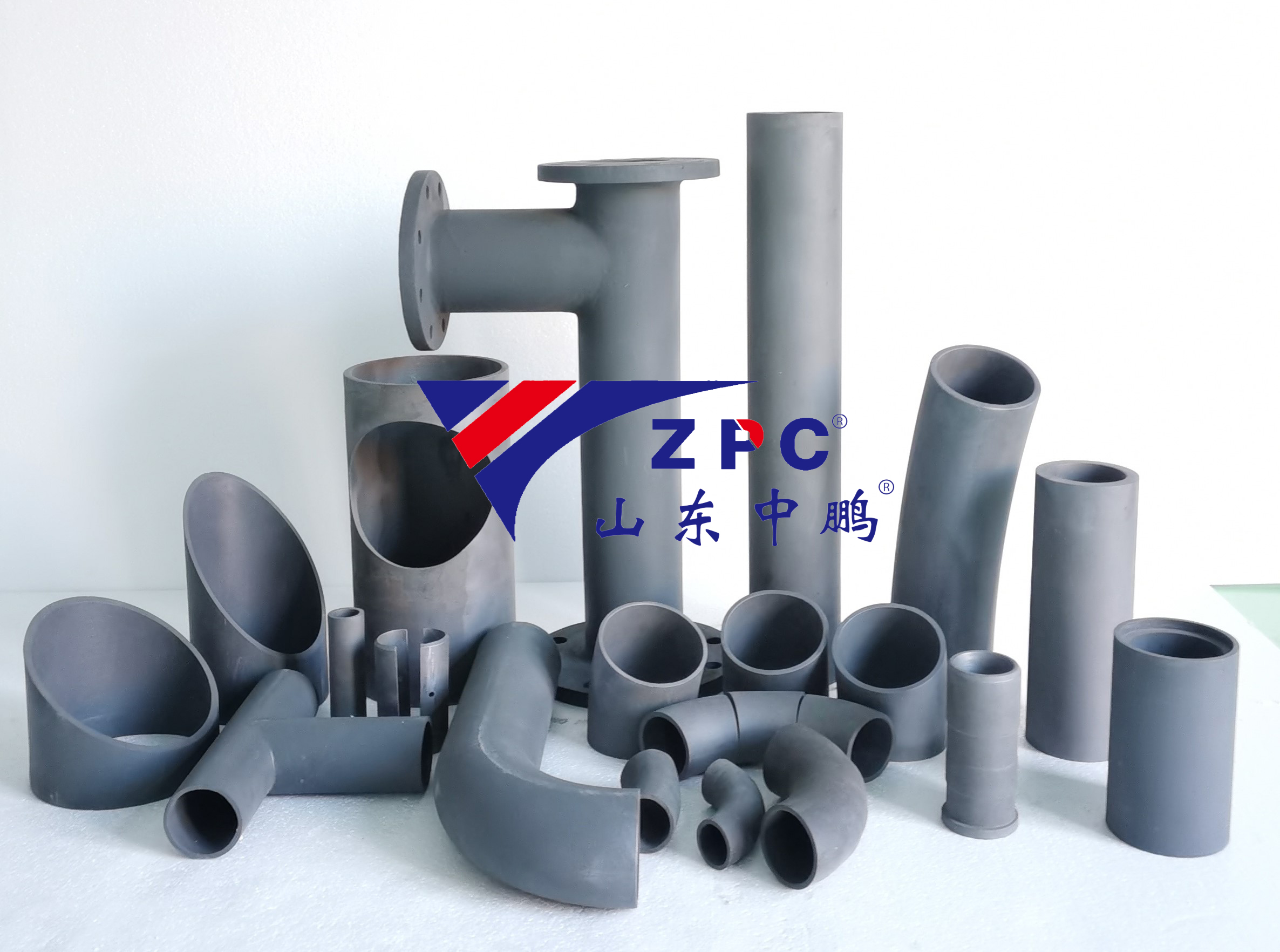

ʻO nā paipu i hoʻopaʻa ʻia ʻo Silicon Carbide.

![]() ʻO ka Reaction bonded silicon carbide (SiSiC a i ʻole RBSIC) kahi mea kūpono kūpono no ka abrasive, coarse particles, classification, concentration, dehydration a me nā hana ʻē aʻe.

ʻO ka Reaction bonded silicon carbide (SiSiC a i ʻole RBSIC) kahi mea kūpono kūpono no ka abrasive, coarse particles, classification, concentration, dehydration a me nā hana ʻē aʻe.

Hoʻohana nui ʻia ia i ka ʻoihana mining, ʻoihana kila, ʻoihana hoʻoponopono ʻākoʻa, kemika

'oihana, maka mea-hana 'oihana, mechanical sealing, surface sandblasted lapaau a me reflector etc. Ka maikai o ka paakiki a me ka abrasive kū'ē, e hiki pono ke pale aku i ka hapa kahi e pono ai ke komo pale, i mea e hooloihi i ke ola lawelawe o ka lako.

■Nā kikoʻī:

■Loaʻa ke ʻano a me ka nui:

Mānoanoa: mai 6mm a hiki i 25mm

ʻAno maʻamau: SISIC pā, SISIC Pipe, SiSiC ʻEkolu Loio, SISIC Elbow, SISIC Cone Cyclone.

Manaʻo: Loaʻa nā nui a me nā ʻano ʻē aʻe ma nā noi.

■Packaging:

I loko o ka pahu pahu, i hoʻopaʻa ʻia i loko o ka pallet lāʻau fumigated me ke kaumaha ʻupena 20-24MT/20′FCL.

■Nā pōmaikaʻi nui:

1. Kūleʻa maikaʻi i ka lole, ka hopena a me ka pale ʻana i ka corrosion;

2. ʻO ka palahalaha maikaʻi a me ke kūpaʻa wela maikaʻi a hiki i 1350 ℃

3. Hoʻokomo maʻalahi;

4. ʻOi aku ka lōʻihi o ke ola lawelawe (ma kahi o 7 mau manawa ʻoi aku ma mua o ka alumina ceramic a me 10 mau manawa ʻoi aku ma mua o ka

polyurethane

Hoʻolālā o ka paipu me ka uhi seramika:

ʻO nā mea waiwai: RBSiC, SiSiC, SSiC, 99.5% Alumina, 99% Alumina, 95% alumina

- ʻO nā paipu, ka hana ma ke ʻano holoʻokoʻa;

- Pāpā, pā ʻālohilohi

- Tile, tile ceramic.

ʻO ke ʻano o ka abrasion hopena o ke kihi haʻahaʻa

Ke paʻi ke kahe o nā mea abrasive i kahi ʻili ʻaʻahu ma kahi kihi pāpaʻu a i ʻole e like me ia, ʻo ke ʻano o ka ʻaʻahu i hana ʻia i ka friction i kapa ʻia ʻo sliding abrasion.

Hāʻawi nā seramika silicon carbide kiʻekiʻe i ke kūpaʻa a me ka pale ʻana i ka corrosion tile a me ka lining. Ua hōʻoia ʻia kēia mau huahana i ka ʻaʻahu ʻana o nā mea hana i ka lawe ʻana, ka hana ʻana, a me ke kaʻina mālama. Hiki ke hana ʻia kā mākou tile me ka mānoanoa mai 8 a 45mm. he mea nui e hōʻoia e hiki iā ʻoe ke loaʻa nā huahana i makemake ʻia. SiSiC: ʻO 9.5 ka paʻakikī o Moh (ʻo 13 ka paʻakikī o Moh hou), me ke kū'ē maikaʻi loa i ka erosion a me ka corrosion, abrasion maikaʻi loa - kū'ē a me ka anti-oxidation. He 4 a 5 mau manawa ʻoi aku ka ikaika ma mua o ka nitride paʻa silicon carbide. ʻO ke ola lawelawe he 5 a 7 mau manawa lōʻihi ma mua o ka mea alumina. ʻO ka MOR o RBSiC he 5 a 7 mau manawa o ka SNBSC, hiki ke hoʻohana ʻia no nā ʻano paʻakikī. He conductive ka lole seramika pale e hoʻomaikaʻi i ka hana hana, ka hana pono, ka hoʻemi ʻana i nā kumukūʻai mālama a me ka hoʻonui ʻana i ka loaʻa kālā.

Loaʻa i nā seramika pololei ka ʻike waiwai, ka ʻike noiʻi a me nā mākau ʻenekinia. Hiki i kēia ke hōʻoia pono i ka hāʻawi ʻia ʻana o nā hopena maikaʻi loa i kā mākou mea kūʻai. Hoʻohana pinepine ʻia nā tile silika carbide a me ka lining i nā noi e like me nā cyclones, tubes, chutes, hoppers, pipes, conveyor belts a me nā ʻōnaehana hana. I loko o ka ʻōnaehana, aia nā mea neʻe e paheʻe ana ma ka ʻili. Ke paheʻe ka mea ma luna o kahi mea, hoʻopau mālie ia i nā ʻāpana a ʻaʻohe mea i koe. Ma nā wahi ʻaʻahu kiʻekiʻe, hiki ke hana pinepine kēia a ke kumu i nā pilikia pipiʻi. Mālama ʻia ka hale nui ma ka hoʻohana ʻana i kahi mea paʻakikī loa, e like me ka silicon carbide ceramics a me ka alumina ceramics ma ke ʻano he lining mōhai. I ka manawa like, hiki i ka silicon carbide ceramics ke hoʻomanawanui i ka lole lōʻihi ma mua o ka pono e hoʻololi ʻia, ʻo ke ola lawelawe silicon carbide ceramic he 5 a 7 mau manawa ma mua o nā mea alumina.

E hoʻohana i nā ʻāpana seramika Silicon Carbide kūpaʻa a me nā waiwai lining:

Paʻa kemika

Uila insulative

Mechanical erosion & Abrasion kū'ē

Hiki ke pani

ʻO nā mea maikaʻi o ka Ceramic Wear Resistant Tile & Linings:

Hiki ke hoʻohana ʻia i kahi e koi ʻia ai nā tolerances paʻa a i ʻole nā linings lahilahi

Hiki ke hoʻohana ʻia no ka hoʻokuʻu hou ʻana i nā wahi e kū nei

Hiki ke hoʻohana ʻia me nā ʻano hoʻopili he nui e like me ka welding a me nā adhesives

Hoʻolālā ʻia no nā noi kikoʻī

Kiʻekiʻe corrosion kū'ē

Hoʻohaʻahaʻa lole māmā

Mālama i nā ʻāpana hoʻoneʻe e pili ana i nā kaiapuni kiʻekiʻe

ʻOi aku ka lōʻihi o ka lōʻihi a ʻoi aku ka maikaʻi o ka hoʻohana ʻana i nā hopena hōʻemi

Ka wela hoʻohana kiʻekiʻe kiʻekiʻe a hiki i 1380°C

1. ʻOihana kila

Pūnaehana hoʻouna: huila bakeke Bai, disc, hopper Du, silo, kāʻei conveyor apron, trolley tee, loaʻa ʻana i ka pahu.

Pūnaehana hui: hui ʻana i ka silo, ka pahu huila Dao mua, ka pahu hui lua lua, ka disc hui ʻana, ka pahu hui ʻana, ka ʻōpala, ka pā pelletizing

Sintering system: beneficiation hopper ma lalo o ka vibrating screen, raw material transport chute, cyclone dust collector and pipeline, fan impeller

2. ʻOihana Sima:

Limestone wawahi nenoaiu a me ka maka a me ka wahie pre homogenization nenoaiu: chute, hopper, kāʻei pahu

Pūnaehana wili maka: kaʻa alakaʻi hoʻokaʻawale, cone hoʻokaʻawale, wili kūpaʻa i ka paipu ʻino, cyclone, wili wahie (mill ball steel), hale hoʻokaʻawale, cone i loko, paipu lanahu pulverized

Mea wili wahie (wili kinipōpō hao): hale hoʻokaʻawale, cone i loko, paipu lanahu pulverized, paipu hoʻihoʻi pauda

3. ʻOihana awa

Hopper paʻa no ka moe, pahu no ka mīkini huila bākeke, pahu paʻa no ke kahua hoʻoili kāʻei, hopper no ka wehe moku.

4. ʻOihana hoʻoheheʻe

Pūnaehana hoʻolaha: ʻo ke poʻo, ka silo (ka pahu waena, ka hue huelo), ka pahu pale haʻalulu, ka pahu coke, ka hopper ana.

Pūnaehana hoʻopaʻa ʻana: hopper batching, mea hui mua (ke lua).

Pūnaehana hoʻoheheʻe: hoʻokahi pahu pahu, paipu calcine, hopper batching, hopper lehu, hopper bin waena

5. ʻOihana Kemika:

Pūnaehana hoʻouna: hopper, silo

Pūnaehana hoʻoneʻe lepo: paipu hoʻoneʻe lepo, kuʻekuʻe, pahu pahu a me ka impeller, cyclone

6. ʻOihana lanahu:

Pūnaehana mālama lanahu: chute, hopper, silo

Pūnaehana holoi lanahu: puʻe makani ʻino, puʻe ʻole ʻekolu huahana ʻino, ʻehā huahana ʻehā, pūʻulu ʻino.

Pūnaehana hoʻolaha: pipeline, elbow, pipe, hopper, silo, distribution port

7. ʻOihana mining:

Pūnaehana hoʻouna: hopper silo

ʻO nā keramika hoʻomaʻamaʻa

Wear Resistance

ʻO Cyclone Hoʻokaʻawale oʻu

Puhui PU

Huihui Polyurethane

Sisic Lined Steel

ʻO ka keramika refractory

SISIC pahu pale

lima pale RBSIC

Nozzle Puka Puka Silicon Carbide

ʻO ka pahu nozzle Silicon Carbide

E-Cigaret Lako

ʻO nā keramika hoʻomaʻamaʻa

Lako Kiln

Kūleʻa wela kiʻekiʻe

Hoʻopili ʻia ʻo Silicon Carbide

Nā lako pale kaua

Anti-puncture

Palekana Abrasion

Kūʻē

Kila kohu ʻole

Hana ʻia ma Kina ʻAʻahu-Paʻa Keramics Compound Polyurethane

Puhui Kina PU

ʻO ka Polyurethane Hui Kina

Alumina Ceramic

Paipu

1650c kiʻekiʻe wela Sic Tube

Hana ʻia ma Kina Wear-Resistant Ceramic Composite PU

Kiʻekiʻe Presicion Silicon Carbide Ceramics

Kiekie maemae Silicon Carbide apo

Nā ʻāpana Ceramic Silicon Carbide

Nā ʻāpana Seramika

ʻO nā mea hoʻopili silika Carbide

Nā mea hoʻoheheʻe keramika

Hana ʻia ma Kina Wear-Resistant Ceramic Composite Sisic Lined Steel

Mahele Keramika

Hana ʻia ma Kina Wholesale Certified Wear-Resistant Ceramic Composite Polyurethane

Paʻakiki Kiʻekiʻe

92% alumina

Hana ʻia ma Kina ʻOihana Wear-Resistant Ceramic Composite Polyurethane

ʻO Shandong Zhongpeng Special Ceramics Co., Ltd ʻo ia kekahi o ka silicon carbide ceramic mea hoʻonā hou i Kina. ʻO ka ʻenehana loea SiC: ʻO 9 ka paʻakikī o Moh (ʻo 13 ka paʻakikī o New Moh), me ke kūpaʻa maikaʻi loa i ka erosion a me ka corrosion, abrasion maikaʻi loa - kūpaʻa a me ka anti-oxidation. ʻO ke ola lawelawe o ka huahana SiC he 4 a 5 mau manawa lōʻihi ma mua o 92% alumina mea. ʻO ka MOR o RBSiC he 5 a 7 mau manawa o ka SNBSC, hiki ke hoʻohana ʻia no nā ʻano paʻakikī. He wikiwiki ke kaʻina hana, ʻo ka hāʻawi ʻana e like me ka mea i ʻōlelo ʻia a ʻoi aku ka maikaʻi o ka lua. Ke hoʻomau mau nei mākou i ka hoʻokūkū i kā mākou mau pahuhopu a hāʻawi i ko mākou naʻau i ke kaiāulu.