1. Ke kū'ē i ka corrosion

Nā nozzles FGDhana i loko o nā kaiapuni ʻino loa i loaʻa nā sulfur oxides, chlorides, a me nā mea ʻē aʻe. Hōʻike ʻo Silicon carbide (SiC) ceramic i ke kūʻokoʻa o ka corrosion kūʻokoʻa me ka liʻiliʻi o 0.1% ka pohō nui ma ka pH 1-14 solutions (ma ka ASTM C863 hoʻāʻo). Hoʻohālikelike ʻia me ke kila kila (PREN 18-25) a me nā nickel alloys (PREN 30-40), mālama ʻo SiC i ka kūpaʻa o ke kūkulu ʻana me ka ʻole o ka pitting a i ʻole ke koʻikoʻi i ka haki ʻana o ka corrosion a i loko o nā waikawa concentrated i nā mahana kiʻekiʻe.

2. Paʻa Kūlana Kiʻekiʻe

ʻO nā mahana hana i loko o nā ʻōnaehana desulfurization kinoea wai maʻamau ma waena o 60-80°C me nā spike ma mua o 120°C. Mālama ʻo SiC ceramic i ka 85% o kona ikaika wela o ka lumi ma 1400 ° C, ʻoi aku ka maikaʻi o ka alumina ceramics (e nalowale ana i ka 50% ikaika e 1000 ° C) a me nā kila wela. ʻO kāna conductivity wela (120 W / m · K) hiki ke hoʻopau maikaʻi i ka wela, pale i ka hoʻokumu ʻana o ke kaumaha.

3. Wear Resistance

Me ka ikaika o Vickers o 28 GPa a me ka paakiki ha'i o 4.6 MPa·m¹/², hōʻike ʻo SiC i ke kūʻē ʻana o ka erosion maikaʻi i nā ʻāpana lehu lele (Mohs 5-7). Hōʻike nā hoʻāʻo kahua i ka mālama ʻana o nā nozzles SiC <5% ʻaʻahu ma hope o 20,000 mau hola lawelawe, ke hoʻohālikelike ʻia me 30-40% ʻaʻahu i nā nozzles alumina a me ka pau ʻole o nā metala polymer-coated i loko o 8,000 mau hola.

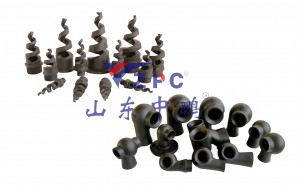

4. Nā ʻano kahe

ʻO ka ʻili wai ʻole o ka SiC i hoʻopaʻa ʻia i ka hopena (contact angle >100 °) hiki ke hoʻopuehu slurry pololei me nā waiwai CV <5%. ʻO kona ultra-smooth surface (Ra 0.2-0.4μm) e hōʻemi ana i ka hāʻule kaomi ma 15-20% i hoʻohālikelike ʻia me nā nozzles metala, ʻoiai e mālama ana i nā coefficients hoʻokuʻu paʻa (± 1%) ma luna o ka hana lōʻihi.

5. Ka maʻalahi o ka mālama ʻana

Hiki i ka inertness kemika o SiC ke kaʻina hana hoʻomaʻemaʻe e like me:

- Puka wai kiʻekiʻe (a hiki i 250 bar)

- ʻO ka hoʻomaʻemaʻe kani ultrasonic me nā hopena alkaline

- Hoʻomaʻamaʻa mahu ma 150°C

Me ka pilikia ʻole o ka hoʻohaʻahaʻa ʻana i ka ʻili i maʻamau i nā nozzles metala polimer-lined a i uhi ʻia.

6. Hoʻokele waiwai

ʻOiai ʻo nā kumu kūʻai mua no nā nozzles SiC he 2-3 × kiʻekiʻe ma mua o ke kila stainless 316L maʻamau, ʻo kā lākou 8-10 makahiki lawelawe ola (vs 2-3 mau makahiki no nā metala) e hōʻemi ana i ke alapine hoʻololi e 70%. Hōʻike ka nui o nā kumukūʻai nona ka 40-60% mālama ma mua o 10 mau makahiki, me ka hoʻohaʻahaʻa ʻole no ka hoʻoponopono ʻana i loko.

7. Pili Kaiapuni

Hōʻike ʻo SiC i ka hana like ʻole i nā kūlana koʻikoʻi:

- Ke pale ʻana i ka paʻakai: 0% hoʻololi nui ma hope o 5000hr ASTM B117 hoʻāʻo

- Ka hana ʻana i ka wai ʻakika: Kū i nā mahu 160°C H2SO4

- Ke pale ʻana i ka haʻalulu wela: Ola i ka 1000°C→25°C i nā pōʻai kinai

8. Nā Waiwai Anti-scaling

Hoʻokumu ka covalent atomic structure o SiC i kahi ʻili non-reactive me nā helu scaling 80% haʻahaʻa ma mua o nā mea ʻē aʻe. Hōʻike nā haʻawina crystallographic i ka hoʻopaʻa ʻana o ka calcite a me ka gypsum i nā mea paʻa nāwaliwali (adhesion <1 MPa) ma SiC versus>5 MPa ma nā metala, hiki ke maʻalahi ka wehe ʻana i ka mīkini.

Manaʻo ʻenehana

Ua puka mai ka silikon carbide ceramic ma ke ʻano he koho waiwai maikaʻi loa no nā nozzles FGD ma o ka loiloi hana piha.

- 10× ʻoi aku ka lōʻihi o ke ola lawelawe ma mua o nā mea ʻē aʻe

- 92% hōʻemi i ka mālama ʻole ʻia

- 35% ka hoʻomaikaʻi ʻana i ka hoʻoneʻe ʻana i ka SO2 ma o nā ʻano hoʻoheheʻe mau

- Hoʻokō piha me ka EPA 40 CFR Māhele 63 mau kūlana hoʻokuʻu

Me ka holomua ʻana o nā ʻenehana hana e like me ka wai-phase sintering a me ka CVD coating, e loaʻa ana nā nozzles SiC o ka hanauna hou i ka sub-micron surface finishes a me nā geometries paʻakikī i hiki ʻole ke loaʻa i nā seramika. Hoʻonoho kēia ʻenehana hoʻomohala i ka silicon carbide ma ke ʻano he mea i koho ʻia no nā ʻōnaehana hoʻomaʻemaʻe flue aʻe.

Ka manawa hoʻouna: Mar-20-2025