Ceramic lined straight pipe

And it has developed rapidly. When transporting the materials with the harder abrasion (such as ash dregs, slag, coal powder, mining dregs, the rest mines, cement, etc), it will exit the problem that the abrasion of pipes is too rapid. Especially, the abrasion of bent pipes is greatly more rapid.

When transporting the special abrasion materials or erosive materials, it will exit the problem that the damage of pipes is too rapid.

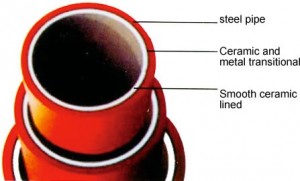

Ceramic lined pipe and the traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe and steel, steel and other rubber pipe is essentially different. Ceramic lined pipe is the outer layer of steel, the inner layer is RBSiC ceramic. Moh’s hardness of up to 13. Wear resistance than carbon steel pipe more than 30 times higher.

At present, the use of our company’s high wear-resistant ceramic lined steel pipe dozens of thermal power plant practice shows that: ceramic lined steel pipe anti-wear ability, anti-fluid erosion ability.

In a duct, the elbow wear the fastest, in practice, Ceramic lined pipe used after 1 to 2 years to open the observation and measurement, the composite layer are no obvious wear or tear off, ceramic-coated steel pipe wear Than the thick-walled wear-resistant cast steel pipe increased by nearly 10 times.

Ceramic lined bend usage

Ceramic lined elbow usage

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a The ceramic lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of the mine filling material, ore powder and tailings transport, coal-fired power plant powder, smelting, ash and other lined with wear-resistant ceramic elbow is also very appropriate.

The SiC ceramic lined pipe, Elbows, Reducer, Tees and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines and the industries of coal, building materials, mechanism, petroleum and so on.

For example, in the condition of hard abrasion, the ceramic steel unbent pipes have been used for several years. But, at present, there is no any ceramic steel unbent pipe has been worn through. Even the ceramic steel unbent pipes with hardest abrasion, their use life is 15 times longer than the cast stone bent pipes and wearable alloy steel bent pipes, 20times longer than the toughened plastic bent pipes and toughened latex bent pipes.

The ceramic lined pipe has captured the market rapidly. Besides the high quality and the wonderful capability, it’s also because its capability price ratio is higher than other wearable, anti-abrasion & anti-hotness pipes.

For the pipes with the same sizes, types and length, the weight of ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter; the weight of ceramic pipe is about 1/3 of the cast stone bent pipe’s, 1/2 of the cast stone unbent pipe’s.

Coal preparation plant site

The cost per meter is equal to the unbent pipe’s, 5%~15% less than the bent pipe’s.

Abrasion resistant pipe in Dense Medium System

Serious wear and tear of the pipeline not only caused a lot of material waste and media running, running, dripping, leakage, and frequent pipeline maintenance replacement, increasing the labor intensity of workers, increased production costs.

Variety classification and code name of wear-resisting pipe in power industry

The abrasion pipe of thermal power plant is mainly conveying raw coal powder, ash slag, flue gas desulfurization (FGD) limestone powder and slurry, due to the transmission of medium velocity fast, poor operating conditions, resulting in pipelines, especially elbow, variable diameter pipe serious wear and corrosion, not only consumes a lot of metal materials, but also to the thermal power plant security, economic operation has brought hidden dangers. The abrasion mechanism of pipeline is mainly based on erosion wear. Wear-resistant pipe can be divided into two categories: single metal pipe and composite pipe.

Silicon carbide alloy ceramic pipe elbow

The crystal structure of sic ceramic wear-resistant elbow is similar to that of diamond tetrahedron, which is a covalent bond, which is a combination of compound, its hardness is high (Morse 9.3), stable performance, physical properties approximate to diamond, it is also called Emery.

The new silicon carbide alloy ceramic Pipe Cay is based on SIC as the main raw material, SIC ceramics are prepared by mixing, molding, drying and high-temperature sintering by rational particle set, adding silica fume, alumina powder and binder. With high hardness, good wear resistance, thermal stability and resistance to chemical corrosion and other excellent performance, especially with the abrasive attack angle is not sensitive to characteristics.

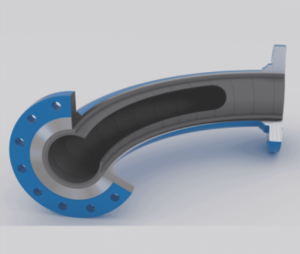

Silicon carbide alloy ceramic pipe elbow with flange. Inner wall diagram of silicon carbide wear-resisting elbow.

Product performance

SIC has a strong hardness (more than nine grades), its wear resistance is alloy steel, wear-resistant cast iron more than 10 times times. And the acid, alkaline substances have a good resistance to decay.

SIC ceramics at 1500-degree high-temperature sintering, with high temperature resistance, can be used in the environment under 1450 degrees, and has a good thermal conductivity, thermal conductivity of more than 12.

Product Index

Protection the internal surfaces of the educator

reaction bonded silicon carbide are used by ZPC to protect the internal surfaces of the eductor against wear and corrosion caused through handling abrasive materials.

The ceramic lining systems have provided in excess of 200 times greater operational life than that obtained from cast iron before replacement is necessary.

Understanding of Metal Tubing within Ceramic lining Related Video:

, , ,