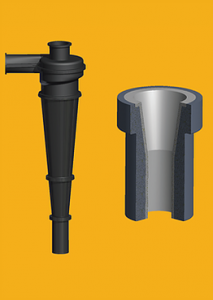

Wear resistance SiC ceramic inner lining

The reaction-sintered silicon carbide ceramic bushings are characterized by high hardness, wear resistance, impact resistance, high temperature resistance, and resistance to acid and alkali corrosion. Its actual service life is more than 7 times that of polyurethane materials and more than 5 times that of alumina materials. This product is suitable for mining industry, mixing industry and others with the characteristics of strong corrosion, coarse particle classification, concentration, dehydration and so on. In the coal, water conservancy, and oil exploration industries, this product also has a wide range of applications. For example, silicon carbide ceramic cones, elbows, tees, arc plate patches, liners, silicon carbide cyclone linings, etc., are particularly suitable for beneficiation industries.

ZPC designs and manufactures high performance hydrocyclone liners and ancillary components from advanced ceramic materials, for use in extreme abrasive and corrosive environments.

Advanced RBSiC ceramics, with new Moh’s hardness ratings of up to 13, are amongst the hardest materials available, except for diamond. They are considerably more wear resistant than stainless steels, ni-hard and stellite materials traditionally used in the manufacture of these types of hydrocyclones.

Our hydrocyclones are designed to split entrapped solids from most liquids in ambient and high temperature abrasive and corrosive environments.

We have supplied many designs of advanced SiC ceramics hydrocyclone for use in the oil, use in the mine, and other manufacturing industries.

Wear resistance SiC ceramic inner lining Related Video:

, , ,