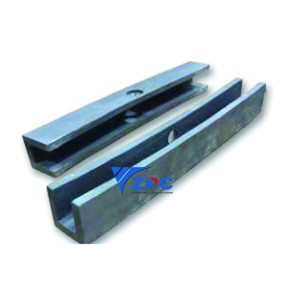

Reaction Bonded Silicon Carbide for Irregular Wear Parts and Thrust Bearings

The Reaction Bonded Silicon Carbide tolerates a wide range of acids and alkalis. And with excellent performance of high strength, high hardness, high wear resistance, high temperature resistance, corrosion resistance. The different kinds of shapes of special parts are suitable for mining, petrochemical, metallurgical manufacturing, aerospace and nuclear industries, such as a specific environment. We can make any sizes provided according to the customer request.

Wear resistance, high temperature strength and corrosion resistance make Reaction Bonded SiC an ideal material for wear components, such as screws, plates and impellers. It can also be used in thrust bearings that can carry extremely high loads in heavily contaminated liquids.

SiC bolts and hangers are widely used in cement industry, wear resistant block and irregular parts are used in steel industry, thermocouple tube in alumina industry, Crucibles and sagers used in carbon material processing industry and other high temperature kiln inner lining, tube linings and so on.

As a new cearmic material, it has many advantages:

Abrasion / Corrosion resistance

Excellent thermal shock characteristics

Excellent oxidation resistance

Good dimensional control of complex shapes

High thermal conductivity

Improved performance

Longer life between replacement / rebuilds

Resistance to corrosion

Superior Resistance to wear

Strength at high temperature up to 1380°C

SiC ceramic pump light-duty, of which the flow-through-parts are made of resin bonded SiC material. It is featured with anti-corrosion and anti-abrasion, very suitable for fulid that contains suspended particles, fouling or gas. It is widely applied to fields of desulfurization, phosphorus industry, alumina oxide, coal-fired plant, metallurgy and paper mill. For many corrosive and abrasive stations, SiC ceramic pump in LVT series are the first choice.

Silicon Carbide Ceramics for Industry Related Video:

, , ,