Hollow cone nozzles demonstrate how simple nozzles can be refined for special purpose. Where a fine, uniform cone of spray is needed, for applications as diverse as cooling gases or humidification, these precisely engineered nozzles are perfect for mass transfer purposes.

How does a hollow cone nozzle work?

Hollow cone nozzles utilise precision-engineered ‘swirl inserts’ to produce fine, atomised liquid flows characterised by ring-shaped impact areas with a concentration of liquid on the edge of the spray pattern. As a result of the swirl effect, the contact surface of the atomised liquid is greatly increased, compared to standard nozzles. Allied to a narrow droplet spectrum (the drop-size distribution or the range of droplet sizes in the spray), this ensures optimum conditions for mass transfer – as required for processes such as gas cooling and cleaning.

Two main types

There are two main types of hollow cone nozzle: axial use a swirl insert to create a hollow cone, low-impact spray with a maximum angle of 90°; tangential (also referred to as eccentric-flow hollow cone nozzles) turn the liquid flow through 90° and use an integral swirl chamber to deliver spray angles up to 130°. The latter differs from the former in the following ways:

- Coarser droplets

- Large free cross-sections

- Wider spray angles

- Self-cleaning/non-clogging properties

- Enhanced operational safety (even with poorer quality water supply)

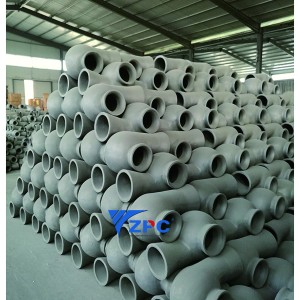

The nozzles, generally featuring two-part construction, are typically manufactured from stainless steel or brass. Leading manufacturers also produce nozzles in other materials.

Uses and applications for this cone nozzle

In general, the efficiency and spray pattern of these nozzles is suitable for processes including these:

- Gas scrubbing and cooling

- Absorption processes

- Dust control (the spray pattern is particularly suitable)

- Dampening of product

- Spraying oils

- Air humidification

Tangential versions are particularly suited to use in air-conditioning installations as well as for cleaning gases in chemical or environmental engineering processes.

Desulphurization Vortex Nozzle – Perfect For Mass Transfer Roles Related Video:

, , ,