Good Quality Helmet Test Machine - RBSiC sandspit nozzle – ZhongPeng

Good Quality Helmet Test Machine - RBSiC sandspit nozzle – ZhongPeng Detail:

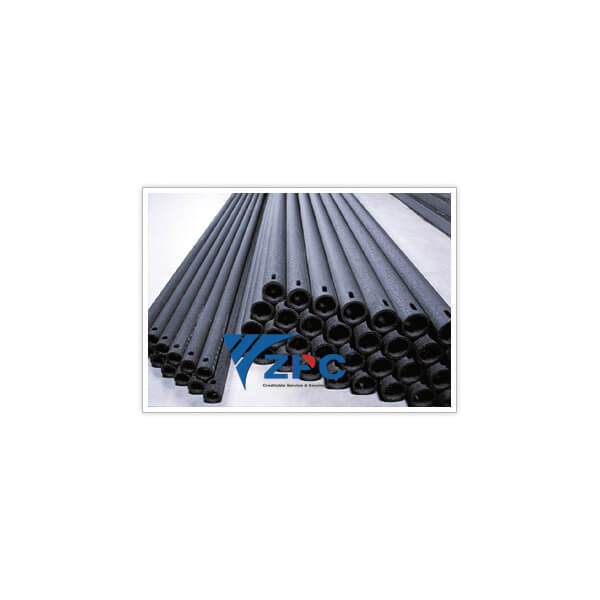

Reaction carbide Silicon Carbide ceramic sandblasting, sandspit, lining, bushings, tube, pipe fittings, and the other products in Shandong Zhongpeng Special Ceramics Co., Ltd have been widely used in many domestic and foreign mineral processing companies.

Reaction Bonded Silicon Carbide (or RBSC, or SiSiC) products offer extreme hardness/abrasion resistance and outstanding chemical stability in aggressive environments. Silicon Carbide is a synthetic material that exhibits high performance characteristics including:

A. Excellent wear and impact resistance.

RBSiC (SiSiC) is pinnacle of large scale abrasion resistant ceramic technology. RBSiC have high hardness approaching that of diamond. Designed for use in applications for large shapes where refractory grades of silicon carbide are exhibiting abrasive wear or damage from impact of large particles. Resistant to direct impingement of light particles as well as impact and sliding abrasion of heavy solids containing slurries. It can be formed into a variety of shapes, including cone and sleeve shapes, as well as more complex engineered pieces designed for equipment involved in the processing of raw materials.

- Excellent chemical resistance.

The strength of RBSC is almost 50% greater than that of most nitride bonded silicon carbides. Corrosion resistance and antioxidation. It can be formed into a variety of desulpurization nozzle (FGD)

Product detail pictures:

Related Product Guide:

Relationship Between Mechanical Properties and Wear Resistance of Alumina-Zirconia Ceramic Composites

Acid scrubber

Good Quality Helmet Test Machine - RBSiC sandspit nozzle – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.