Good Quality Heating Oil Burner - Reaction-bonded silicon carbide Beam – ZhongPeng

Good Quality Heating Oil Burner - Reaction-bonded silicon carbide Beam – ZhongPeng Detail:

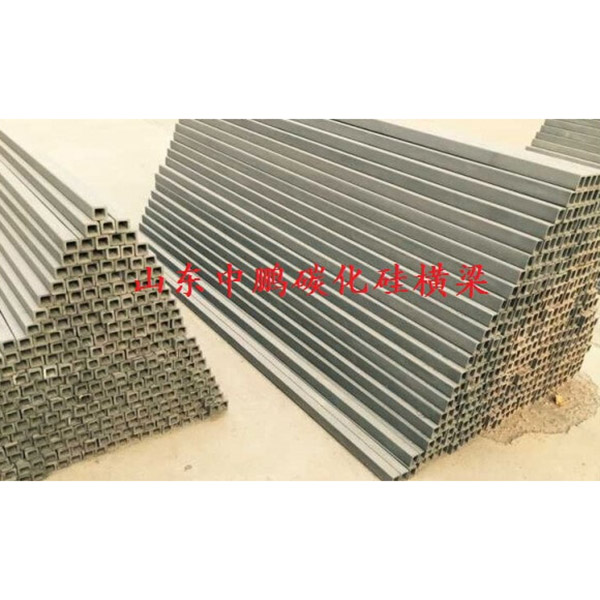

Solid beam poles are used as loading frames in porcelain producing kilns, and which can replace normal oxide bonded silicon plate and mullite post as they have good advantages like save spaces, fuel, energy and also short the firing time, and the life time of this materials is several times of others it is very ideal kiln furniture.

Beams with high – temperature bearing capacity of large, long-term use without bending deformation, especially suitable for tunnel kilns, shuttle kiln, in two – layer roller kiln and other industrial furnace load – bearing structure of frame.

Clubs apply to daily – used ceramics, sanitary porcelain, Building Ceramic, Magnetic material and high temperature firing zone of roller kiln.

Product detail pictures:

Related Product Guide:

SiC FGD desulphurization nozzles

Understanding of Metal Tubing within Ceramic lining

Good Quality Heating Oil Burner - Reaction-bonded silicon carbide Beam – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.