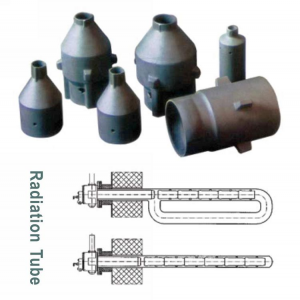

Free sample for Vortex Double Direction Nozzle - Silicon carbide radiant tube – ZhongPeng

Free sample for Vortex Double Direction Nozzle - Silicon carbide radiant tube – ZhongPeng Detail:

Silicon carbide products are the most suitable kiln furnitures of tunnel kilns, shuttle kilns, roller of hearth kilns as the flame tubes.

With high temperature thermal conductivity, good, quick cooling in heat resistance, resistance to oxidation, thermal shock resistance of good, long life.

Features:

• Excellent energy savings.

• Lighter weight and higher load capacity.

• Excellent distortion resistance at high temperature.

• High thermal conductivity

• High Young’s modulus

• Low thermal expansion coefficient

• Extremely high hardness

• Wear resistant

Application:

• sanitary ware

• Kiln furniture crucibles

• glass panel industries

• Sliding bearings

• glost firing of tableware.

• Heat exchangers

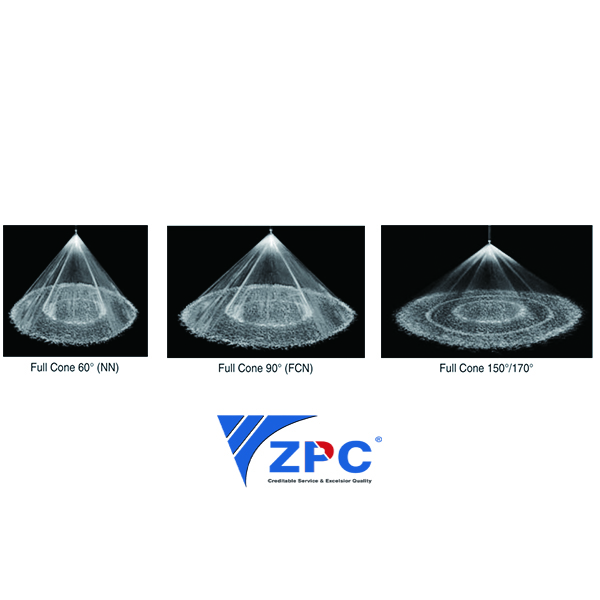

• Burners

• Wear parts (thread guides)

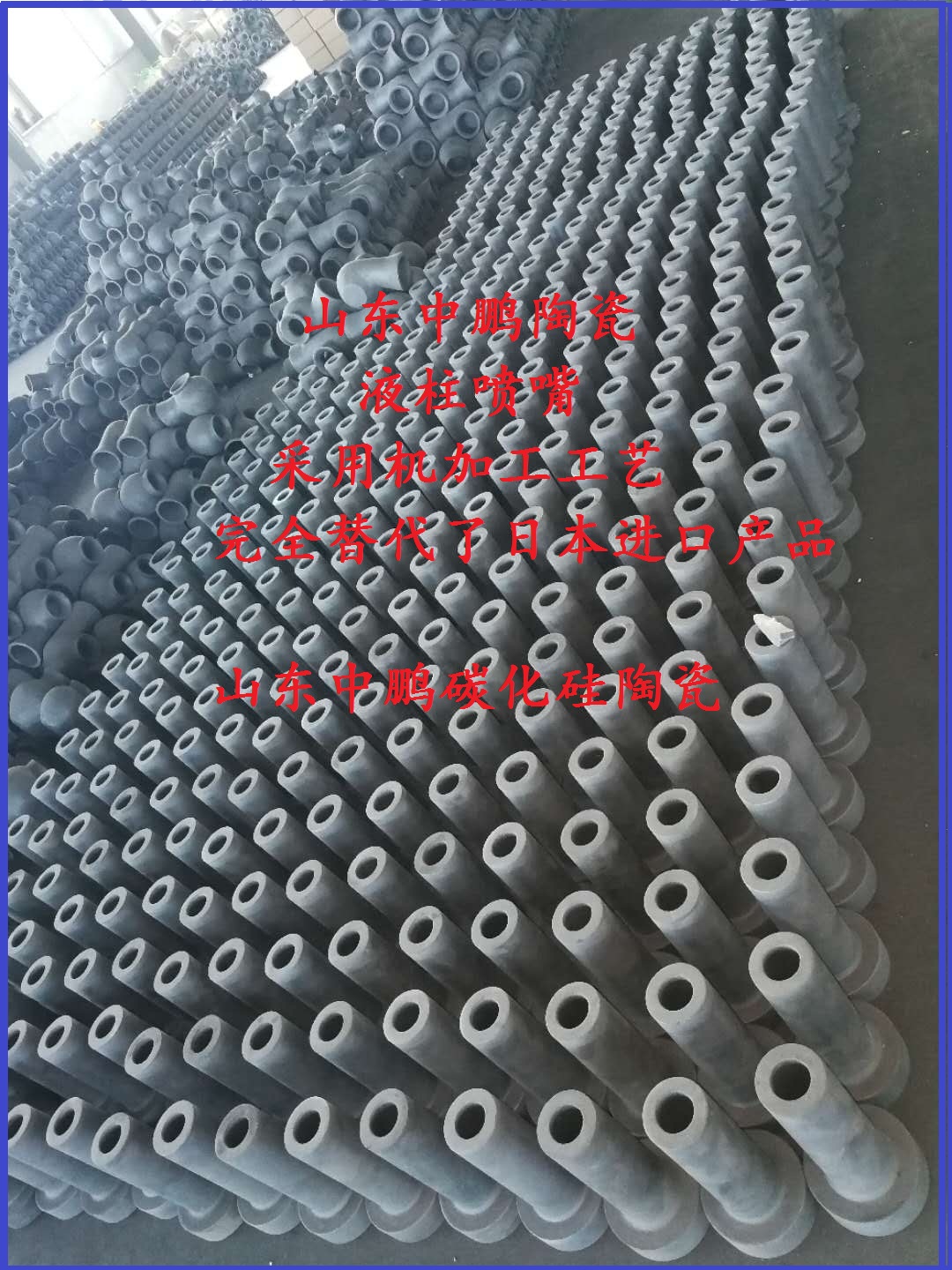

RBSiC(SiSiC) nozzles are used for the high temperature systems of tunnel kilns,shuttle kilns and many

other industrial kilns. RBSiC(SiSiC)cross beams have higher strength and there are no deformations even in very high temperature.

Specification

|

Properites

|

Units

|

Silicon carbide Material

|

||||||

|

Type

|

SiC

|

SiSiC

|

NSiC

|

RSiC

|

||||

|

Chemical composition

|

SiC%

|

89

|

87

|

92

|

70

|

99

|

||

|

SiO2 %

|

5

|

6

|

-

|

Si3N4 28

|

-

|

|||

|

Al2O3%

|

1.0

|

2.0

|

-

|

-

|

-

|

|||

|

Bulk Desity

|

g/cm3

|

2.85

|

2.8

|

3.01

|

2.8

|

2.75

|

||

|

Apparent porosity

|

%

|

12

|

14

|

0.1

|

12

|

14

|

||

|

M.O.R.@20℃

|

MPa

|

50

|

48

|

260

|

180

|

100

|

||

|

M.O.R.@1300℃

|

MPa

|

58

|

56

|

280

|

185

|

120

|

||

|

C.T.E.@20℃-1000℃

|

10-6K-1

|

4.8

|

4.2

|

4.5

|

4.7

|

4.6

|

||

|

C.C.S

|

MPa

|

100

|

90

|

900

|

500

|

300

|

||

|

Thermal shock resistance

|

★

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

||

RBSiC(SiSiC) nozzles/beams/ rollers are used for the loading structure systems of tunnel kilns,shuttle kilns and many

other industrial kilns. RBSiC(SiSiC)cross beams have higher strength and there are no deformations even in very high temperature.

And also the beams display long operational life.The beams are the most suitable kiln furniture for sanitarywear and electrical porcelain applications. RBSiC(SiSiC)has excellent thermal conductivity, so it is available to save energy with less weight of the kiln car.

Packaging &Shipping

1.50 pieces in a wooden box (fully enclosed, safe and secure)

2.800kg~1000kg /wooden box.

3.Anti-collision protection such as foam board

4.3-layer wood composite panel, sturdy, impact resistant, drop resistant

Shipping details

1.Professional car transport to various ports in China, then loaded by a professional shipping company.

2.Both FOB and CIF can be operated flexibly.

3. Competitive sea freight and short transit time.

Product detail pictures:

Related Product Guide:

Wear resistance SiC ceramic inner lining

Acid scrubber

Free sample for Vortex Double Direction Nozzle - Silicon carbide radiant tube – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.