-

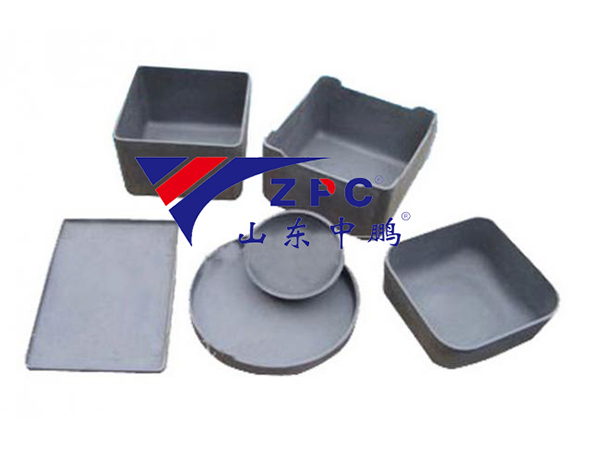

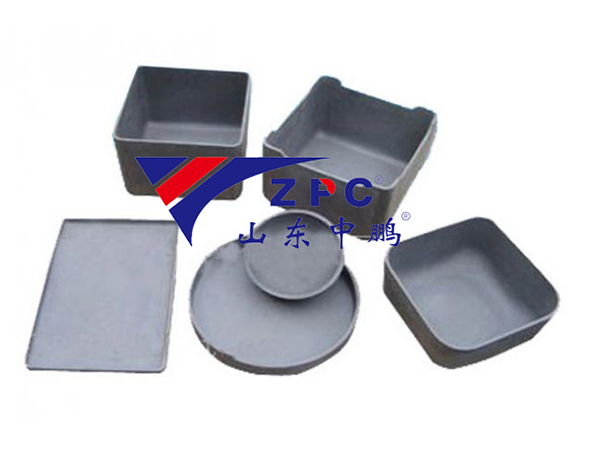

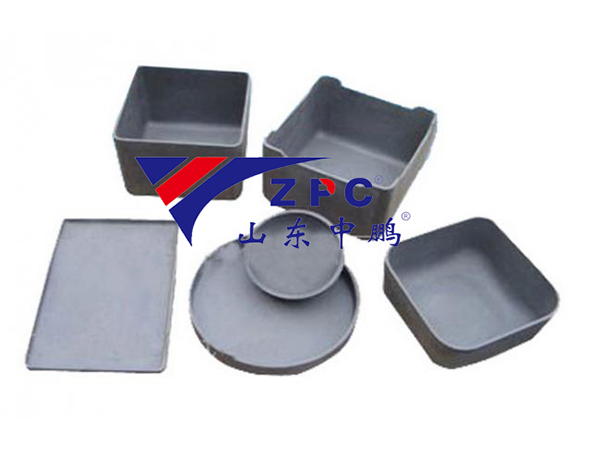

In industries such as metallurgy, chemical engineering, and new energy, there is a seemingly insignificant but crucial container – the crucible. If traditional crucibles are like “iron rice bowls”, then silicon carbide ceramic crucibles are upgraded versions of “titanium a...Read more»

-

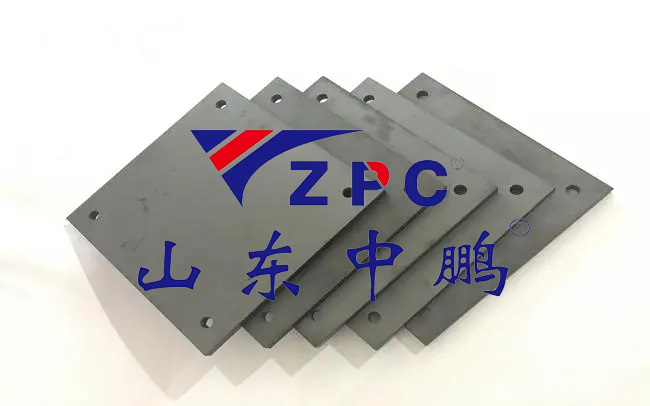

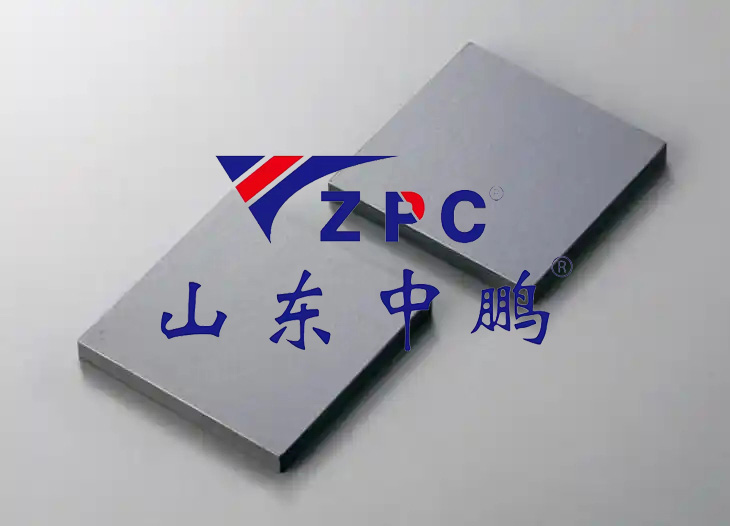

In the world of precision manufacturing, there is a material that silently supports the development of many high-end industries – it is harder than steel, more heat-resistant than graphite, but always maintains a lightweight body. This is silicon carbide ceramic plate, an indispensable R...Read more»

-

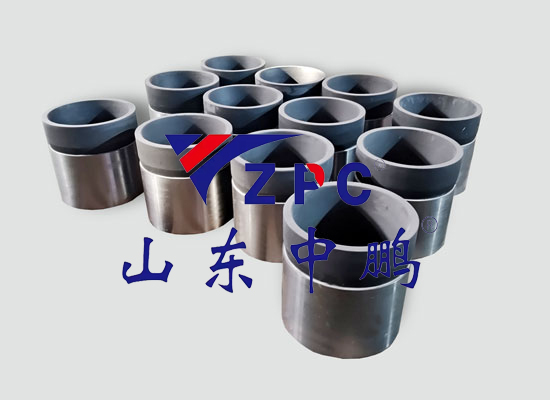

In industrial fields such as mining and metallurgy, hydrocyclones are like tireless “sorting workers”, constantly separating useful minerals and impurities from slurry day and night. Inside this device with a diameter of only a few meters, there is a hidden ultimate weapon against wea...Read more»

-

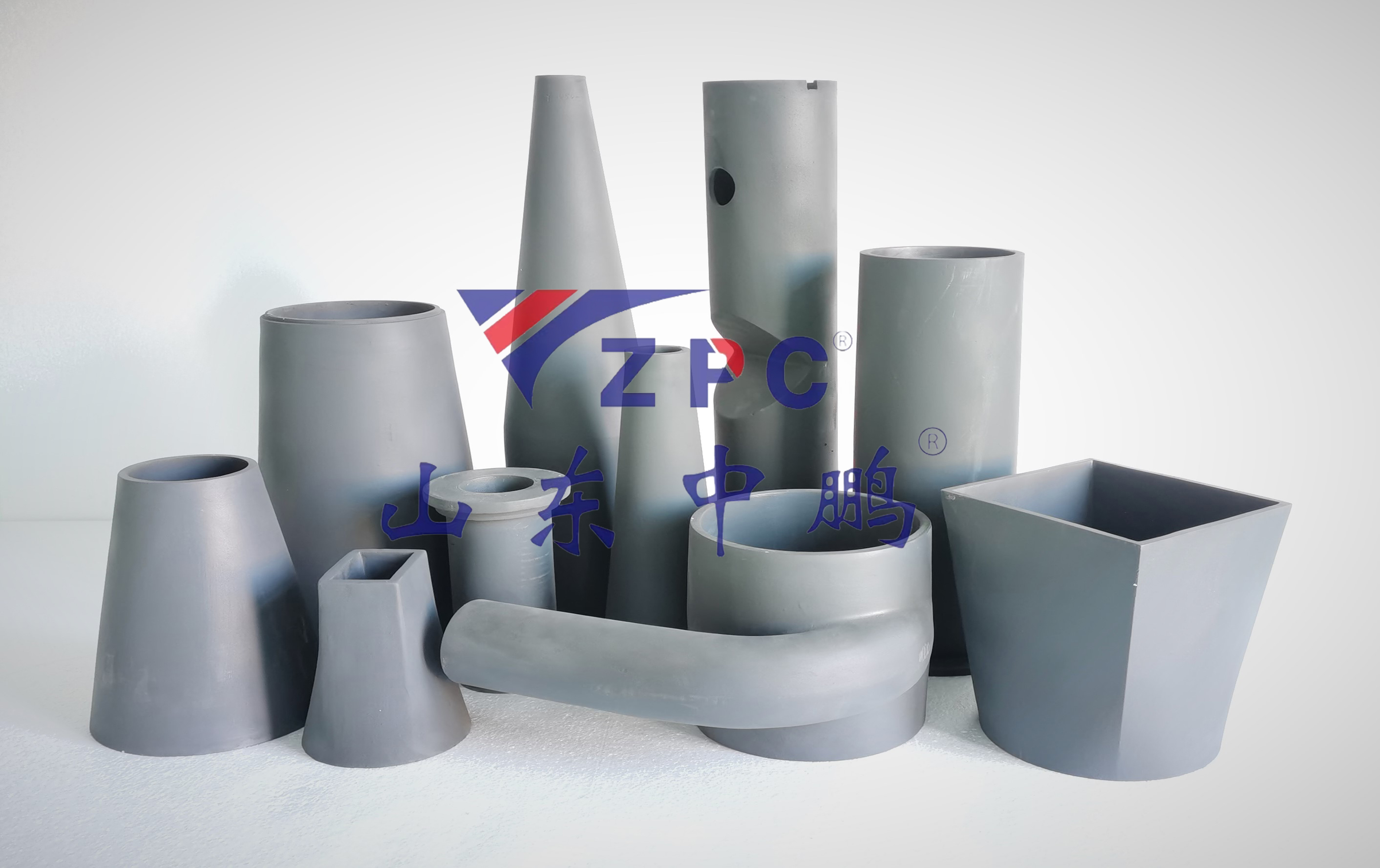

On the battlefield of industrial production, pipeline systems are like the “lifeline” that maintains the operation of enterprises, but they always face the threat of wear and corrosion. When traditional metal pipelines frequently “retreat” under harsh working conditions, a...Read more»

-

In the industrial field where high temperatures, corrosive media, and extreme working conditions frequently occur, traditional materials are often inadequate. As a leader in reaction sintered silicon carbide ceramic technology, we are well aware of how this revolutionary material redefines the bo...Read more»

-

At the scene of the Blue Sky Defense Battle, there is a little-known ‘key gentleman’ silently guarding our respiratory health – it is neither a huge absorption tower nor a complex control system, but a flue gas desulfurization nozzle(FGD spray nozzle) with a diameter of only a f...Read more»

-

Beside the 1000 ℃ kiln, in the industrial environmental protection desulfurization system, and inside the precision optical instruments, there is always a material that silently withstands the test of extreme temperatures – it is silicon carbide ceramics known as “industrial black gol...Read more»

-

In the field of industrial manufacturing, ceramic materials have long broken through the stereotype of “bottle and can” and become the “Iron Man” of modern industry, demonstrating their skills in kilns, pipelines, desulfurization and other fields. Among numerous industrial...Read more»

-

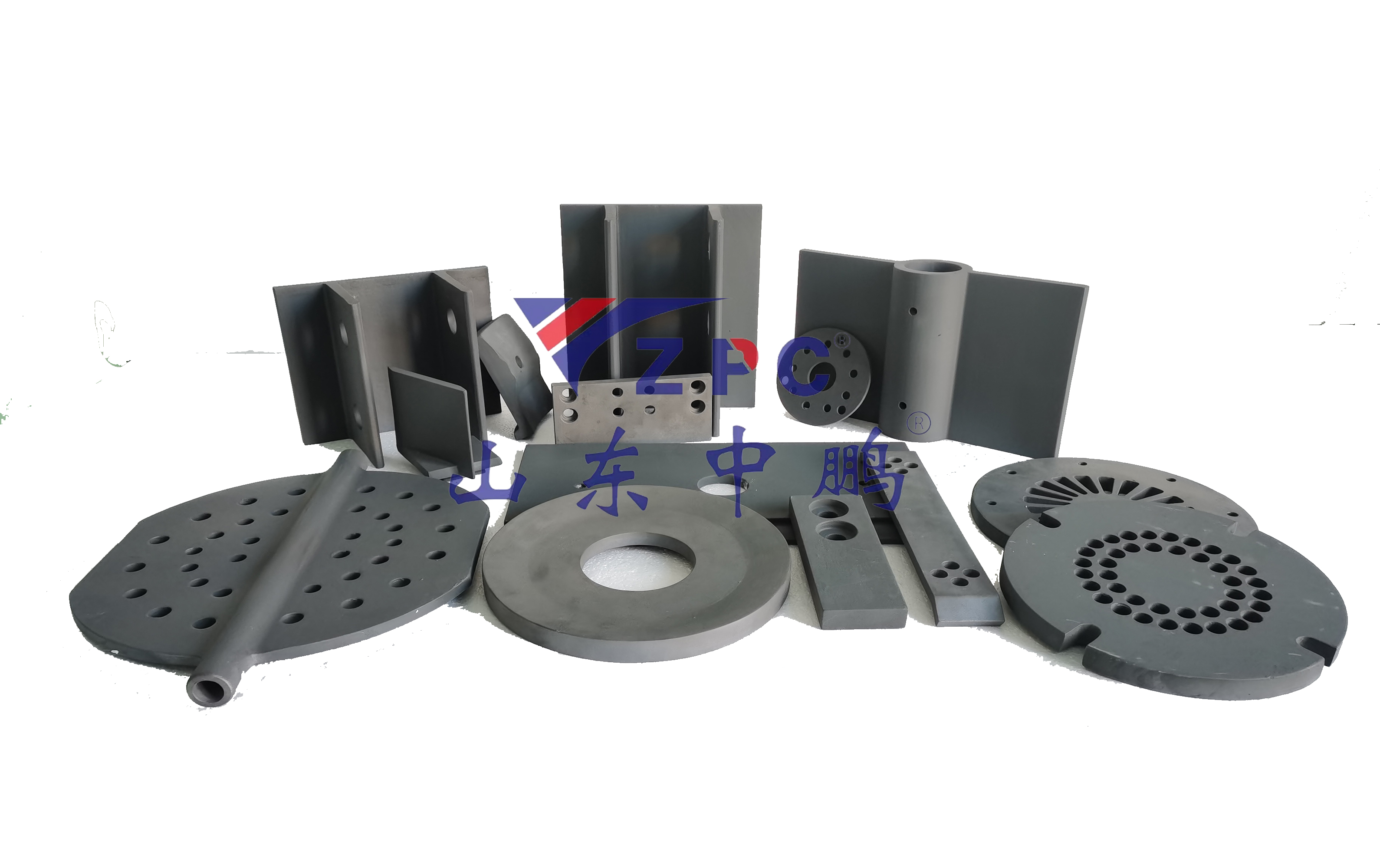

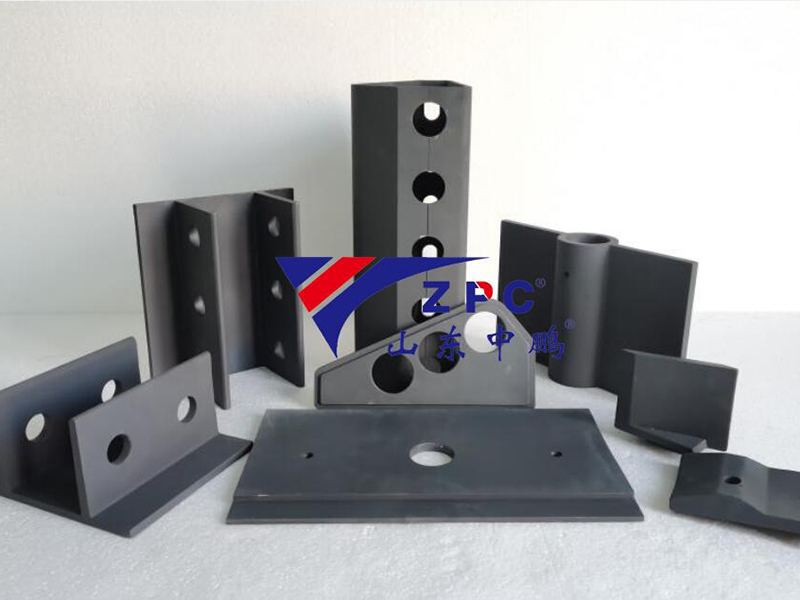

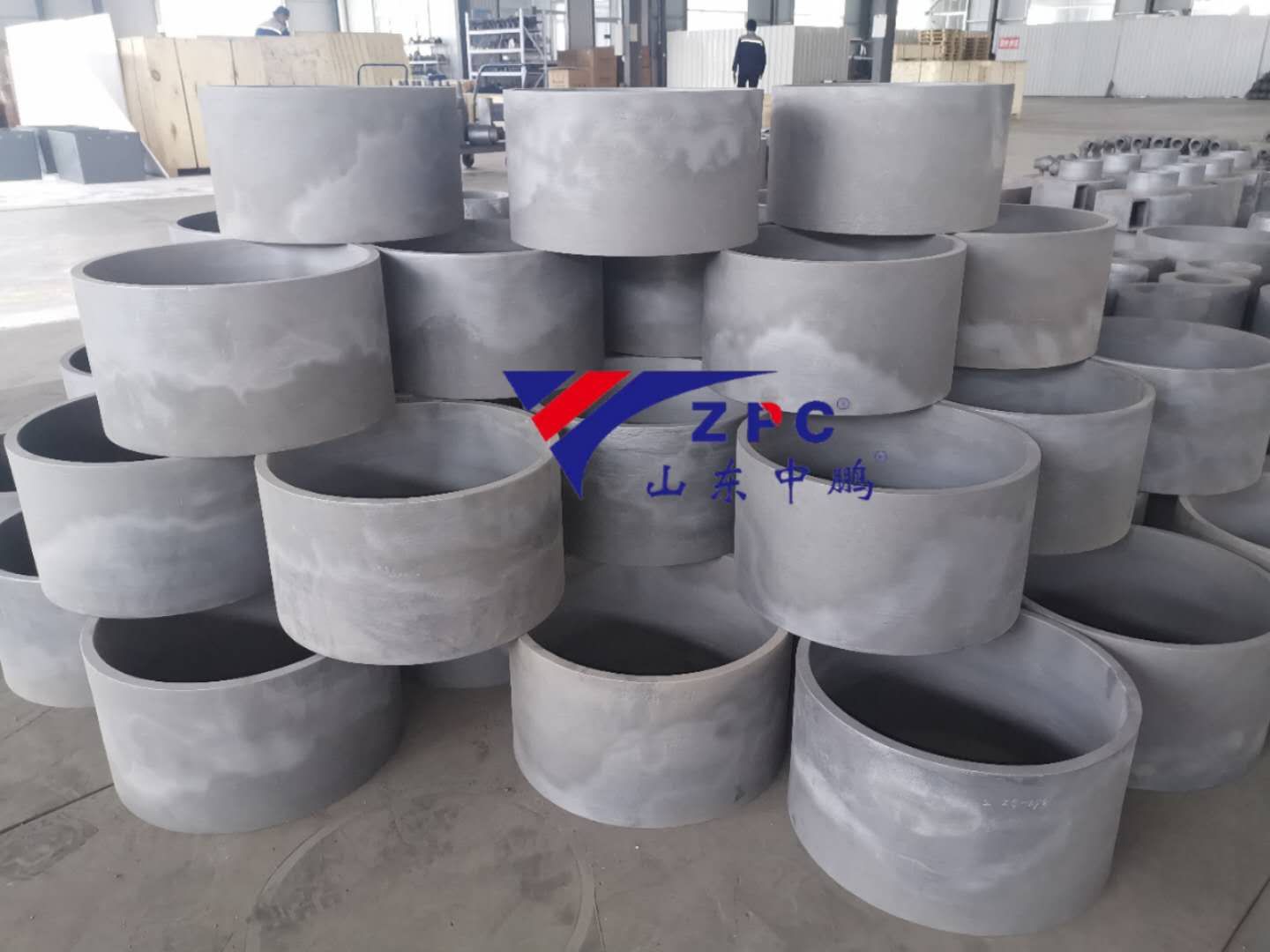

In the high-end industrial manufacturing field, the demand for customized shaped components is increasing day by day. These complex shaped and precision demanding components directly determine the performance and lifespan of the equipment. Faced with multiple tests such as high temperature, corro...Read more»

-

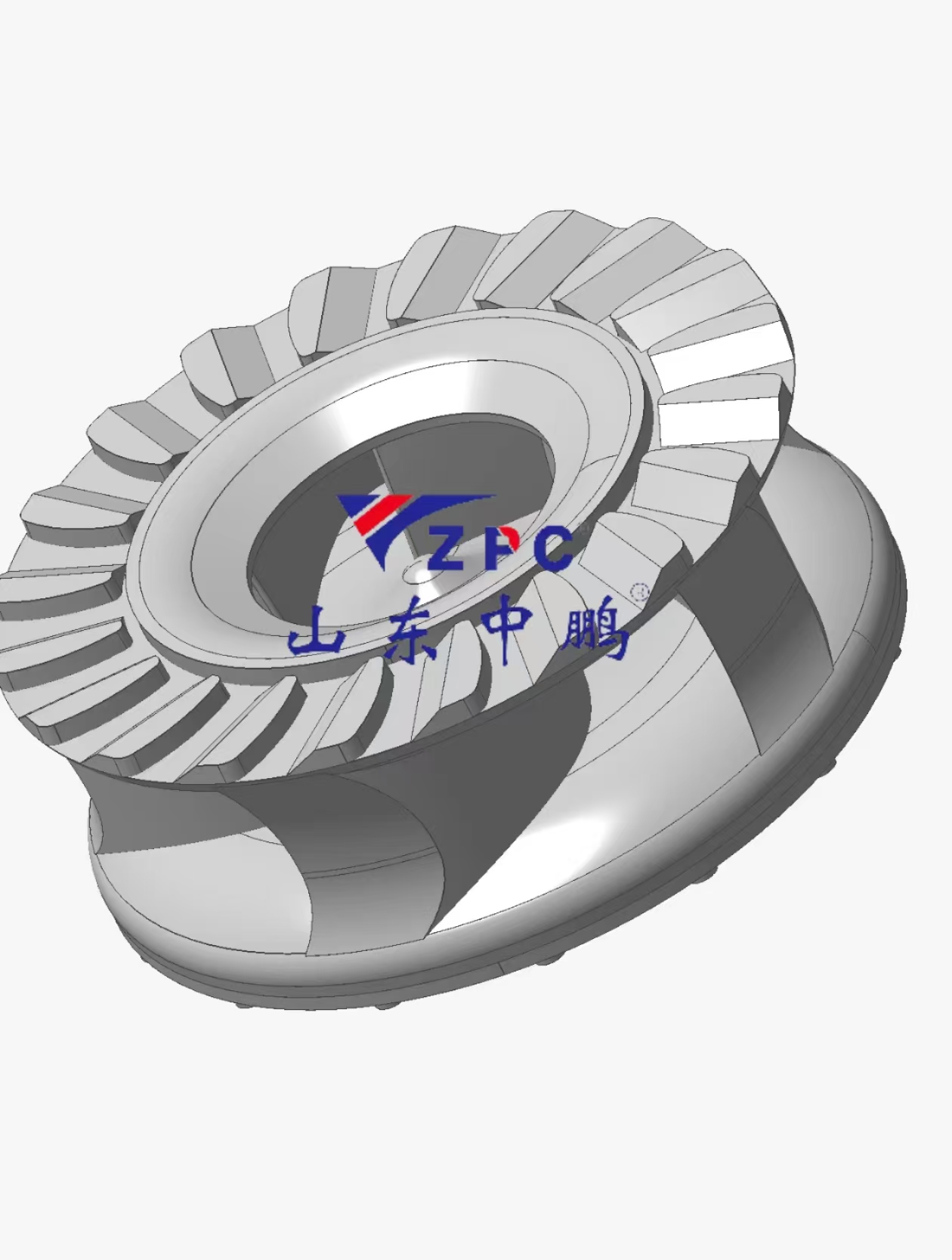

In industrial fields such as mining, metallurgy, chemical and environmental protection, slurry pumps continuously transport corrosive media containing solid particles like the “industrial heart”. As the core component of the overcurrent component, the material selection directly deter...Read more»

-

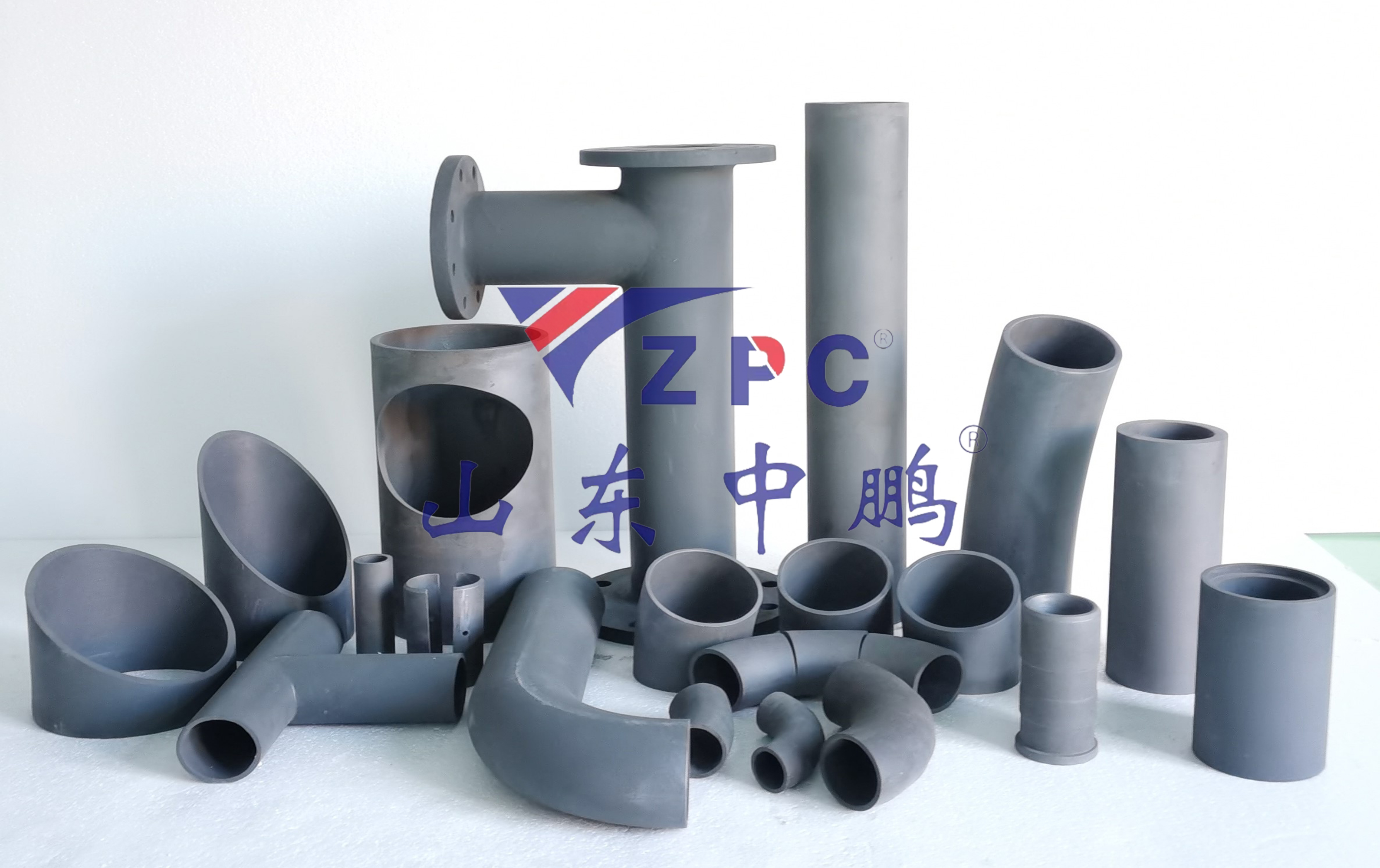

In industrial production, pipelines are like the blood vessel system of the human body, undertaking the critical task of transporting raw materials and waste. However, facing the continuous erosion of materials such as sand, gravel, and slurry, traditional pipelines often become “scarred...Read more»

-

In industrial fields such as mining, metallurgy, and power, slurry pumps are key equipment for transporting high wear and highly corrosive media. Although traditional metal pump bodies have high strength, they often face problems of rapid wear and short service life when facing complex working co...Read more»

-

In the “high-temperature battlefield” of modern industry, traditional metal materials often face challenges such as softening deformation, oxidation and corrosion. And a new type of material called silicon carbide ceramic is quietly becoming the core guardian of high-temperature equip...Read more»

-

In industrial flue gas desulfurization systems, although the nozzle is small, it bears a heavy responsibility – it directly determines the desulfurization efficiency and equipment operation stability. In the face of harsh working conditions such as high temperature, corrosion, and wear, mat...Read more»

-

In the field of industrial production, choosing suitable ceramic materials is like finding reliable partners – it needs to withstand the test of time, withstand extreme environments, and continue to add value to production efficiency. How to make a wise choice in the face of a dazzling arra...Read more»

-

In the field of industrial production, ceramic materials are writing a new legend. Unlike ceramic vessels in daily life, industrial ceramics have demonstrated their outstanding performance in key fields such as metallurgy, chemical engineering, and new energy. Aluminum oxide, silicon nitride, zir...Read more»

-

In the modern industrial field, silicon carbide ceramics are known as the “industrial armor” and have become a key material in extreme environments due to their high strength, high temperature resistance, and corrosion resistance. But what many people don’t know is that the sili...Read more»

-

In high-temperature industries such as metallurgy, ceramics, and chemical engineering, the stability and durability of equipment directly affect production efficiency and costs. As the “throat” component of the combustion system, the burner sleeve has long faced challenges such as fla...Read more»

-

In industries such as metallurgy, chemical engineering, and new energy, there is a seemingly ordinary but crucial equipment – crucible. It is like an unknown ‘high-temperature warrior’, carrying thousands of degrees of molten metal or chemical raw materials, and the crucible mad...Read more»

-

In the precision world of modern industry, the small deformations of materials often determine the ultimate performance of equipment. Silicon carbide ceramics, with their unique physical properties, are becoming an indispensable “rigid guardian” in the high-end manufacturing field. Th...Read more»

-

In the high-temperature industrial field, there is a key component that is as important as the heart of equipment – it is the silicon carbide nozzle. This industrial component manufactured using advanced ceramic technology is providing long-lasting and reliable power support for various hig...Read more»

-

In modern industrial production, pipeline systems are like the “blood vessels” of the human body, undertaking the important task of transporting high-temperature and corrosive media. The silicon carbide (SiC) lining technology is like putting a layer of high-performance armor on these...Read more»

-

In the field of industrial high temperature, achieving safe and efficient heat transfer has always been the key to technological breakthroughs. Silicon carbide radiation tube is a special equipment designed specifically for high-temperature scenarios. It acts like a silent “thermal energy t...Read more»

-

In the industrial scenarios of tunnel kilns and pipeline kilns, the high temperature environment is like a “flame mountain” – equipment components need to withstand long-term roasting above 800 ℃, while also resisting the erosion of oxidizing gases and even acidic gases. Traditi...Read more»

-

In the field of industrial flue gas treatment, the desulfurization system is like a “purifier” that protects the blue sky and white clouds, and the desulfurization nozzle is the “precision joint” of this system. In recent years, desulfurization nozzles made of silicon carb...Read more»