China Factory for Gas Cutting Nozzle Tip - [Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng

China Factory for Gas Cutting Nozzle Tip - [Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng Detail:

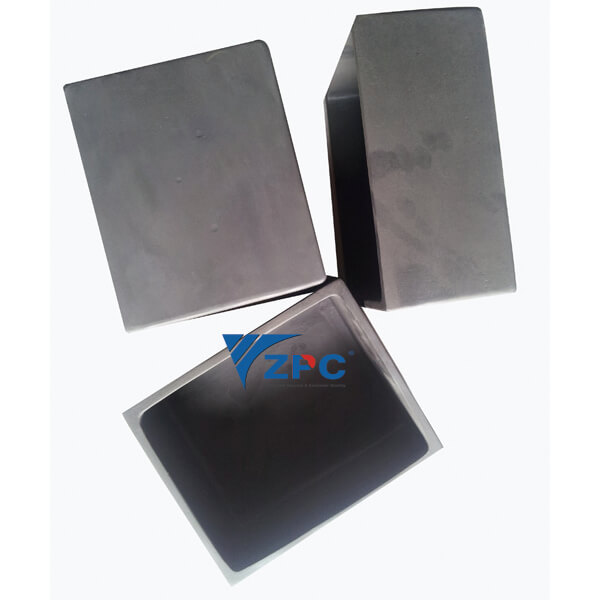

Product series of with angle impact and abrasion

Low angle and sliding abrasion

When flow of abrasive material hits a wear surface at a shallow angle or passes parallel to it, the sliding abrasion will occur.

Advanced silicon carbide ceramics can serve as wear resistance and corrosion resistance ceramic tiles and lining. These products have been proven as useful material used in conveying, processing, and storage process in mining and other perspectives. Our tiles thickness can be ranged from 8mm to 45mm which can meet the requirements of most customers.

Moh’s hardness of SiSiC is 9.5, while its New Moh’s hardness is 13. The material has excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to improve production performance and working efficiency, as well as reducing maintenance costs.

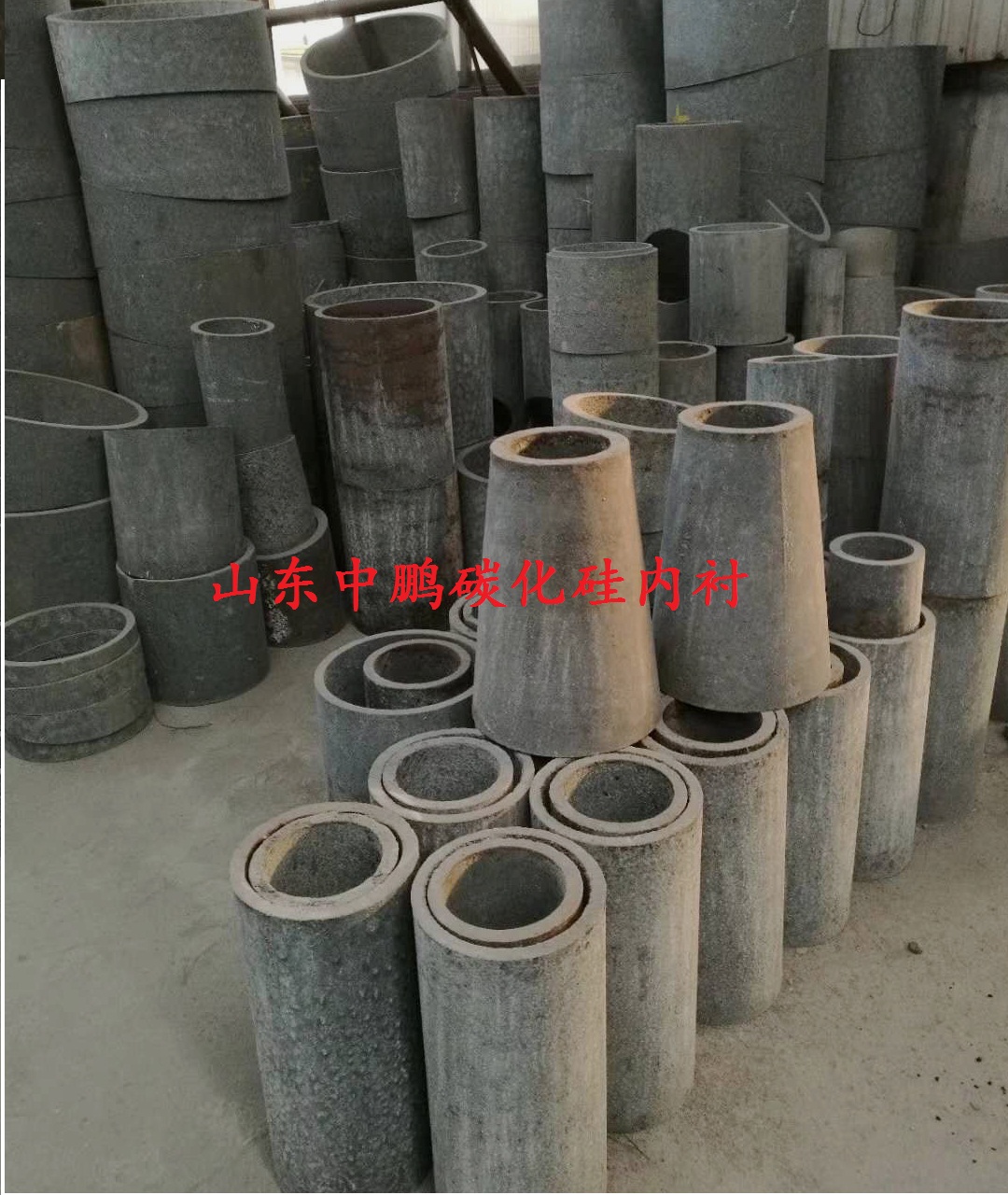

Precision ceramics have material knowledge, applied expertise and engineering skills. This can effectively ensure that the best solutions are offered to our customers. Silicon carbide ceramic tiles and lining are often used in applications such as cyclones, tubes, chutes, hoppers, pipes, conveyor belts and production systems. In the system, there are moving objects sliding on the surface. When the object slides on a material, it slowly wears the parts away until nothing remains. In high wear environments, this can happen frequently and cause a lot of expensive problems. The main structure is retained by using a very hard material, such as silicon carbide ceramics and alumina ceramics as a sacrificial lining. At the same time, silicon carbide ceramics can endure longer wear before it needs to be replaced, the silicon carbide ceramic service life is 5 to 7 times longer than alumina material .

Wear Resistant Silicon Carbide Ceramic Tiles & Lining Properties:

Chemical resistant

Electrically insulate

Mechanical erosion & Abrasion resistant

Replaceable

Advantages of Ceramic Wear Resistant Tiles & Linings:

Can be used where tight tolerances or thin linings are required

Can be used to resurface existing wear prone areas

Can be used with multiple attachment methods like welding and adhesives

Custom designed for specific applications

Highly corrosion resistant

Lightweight wear reduction solution

Protects moving parts that are subject to high wear environments

Significantly outlasts & outperforms wear reduction solutions

Ultra-high maximum use temperature of up to 1380°C

Alumina Ceramic Lining Tile

The basic material for ResisTek’s “Wear Resistance Ceramic” is extreme pure synthetic (Alpha) alumina oxide. Today alumina ceramic of 92% purity is the best solution in terms of wear protection performance and material costs. However, other alumina content such 95% and 99% purity is usually custom made by the customers based on each specific conditions, which require either higher purity, impact or hardness for their applications.

Characteristics

Good wear resistant property and long service life; smooth surface, low friction coefficient, low density and light weight; resistant to all kinds of acid, alkali and salt; low thermal expansion coefficient and thermal conductivity, operating temperature can be up to 1000 centi-degree.

Applications Areas:

Applications Areas:

| • Grinding systems | • Mixer Application areas |

| • separator systems | • chain conveyor |

| • cyclones | • diffusor |

| • pipes | • dedusting systems for coal, ash, sinter |

| • ducts | • sinter slurry ducts |

| • Hooper | • High temperature cyclones |

| • Ventilator housing | • salt plants |

Product detail pictures:

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/27.jpg)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/41.jpg)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/42.jpg)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/Rubber-ceramic-lining.png)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/3.3.png)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/13.png)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/Arc-shaped-plate-3.jpg)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/3.4.png)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/2345_image_file_copy_2.jpg)

![China Factory for Gas Cutting Nozzle Tip -

[Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng detail pictures](https://www.rbsic-sisic.com/uploads/2345_image_file_copy_32.jpg)

Related Product Guide:

SiC FGD desulphurization nozzles

Silicon Carbide Ceramics for Industry

China Factory for Gas Cutting Nozzle Tip - [Copy] Wear resistant customized Silicon carbide & Alumina tiles, Ceramic Liner, tiles, plates, blocks, lining, pipes – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.