The Silicon Carbide ceramic manufacturer

We tries to offer service to industrial customers in electric power, ceramics, kilns, steel, mines, coal, cement, alumina, petroleum, chemical industry, wet desulfurization and denitrification, machinery manufacturing, and other special industries.

Company Profile

We are a high-tech enterprise specializing in the production, research and development, and sales of high-performance silicon carbide products and reaction bonded silicon carbide (RBSC/SiSiC).

Advantages

We have:

Professional technical support, production process and equipments.

Complete production managing system, OEM/ODM is available.

Creditable company and competitive products.

Technology

Excellent chemical resistance.

Excellent wear and impact resistance.

Excellent thermal shock resistance.

High strength (gains strength at temperature).

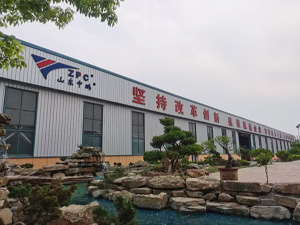

Meet The Factory

Factory exterior

Factory panorama

Machinery

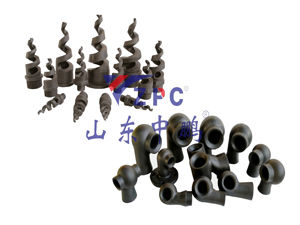

Customized SiC Ceramic Products

If you need customized products of silicon carbide ceramics, please feel free to cooperate with us.

We are willing to cooperate wholeheartedly with new and old customers at home and abroad,

Jointly develop new technologies and products to achieve win-win outcomes.

New Applications of Silicon Carbide Ceramics

The excellent characteristics of silicon carbide ceramics make them no longer limited to industries such as energy conservation and environmental protection, power energy, petrochemicals, metallurgical machinery, mining equipment, kiln equipment, etc., but are increasingly developing in fields such as aerospace, microelectronics, solar converters, automotive industry, and military.

“Building trustworthy enterprises and strengthening international cooperation”

― SHANDONG ZHONGPENG SEPCIAL CERAMICS CO., LTD