92% Alumina tiles, blocks

Alumina tiles:

1. super wear-resistant

2. super corrosion resistant

3. super hardness

4. super density

5. free-contamination

6. prolong the equipment service life

High quality ceramic wear-resistant tiles is an alumina (Al₂O₃)-oriented material with other ingredients, and is sintered through 1700 ℃ of high temperature.

|

Items |

VANNA 92 |

|

Al₂O₃(%) |

92 |

|

Bulk density(g/cm³)

|

>3.63 |

|

Water absorption(%) |

<0.01 |

|

Hardness(Mohs) |

9 |

|

Color |

white |

Standard Dimension

|

Dimension (mm) |

Length |

Width |

Thickness |

|

150*100 |

150 |

100 |

12,15,20,25 |

|

150*60/57 |

150 |

60/57 |

12 |

|

150*50/47 |

150 |

50/47 |

12 |

|

120*80 |

120 |

80 |

10,12 |

|

110*40/37 |

110 |

40/37 |

10 |

|

100*30/37 |

100 |

30/37 |

10 |

|

50*50 |

50 |

50 |

25 |

|

24*24 |

24 |

24 |

8,12 |

|

20820 |

20 |

20 |

5,8,10 |

|

17.5*17.5 |

17.5 |

17.5 |

3,4,5,6 |

|

10*10 |

10 |

10 |

3,4,5 |

- High Quality Ceramic Wear-resistant Tile is widely used in thermal power, iron and steel,metallurgy, mechanical,coal,mine, chemical, cement, port and wharf etc. convenient for all large mechanical equipment with severe abrasions including conveying coal and material system, coal pulverizing system, dust removal system and dust pelletizing system etc. It can select different products according to different requirements.

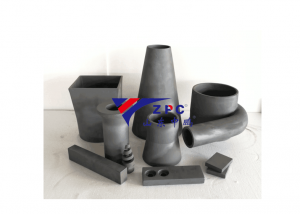

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.